Sulfur/phosphorus-free organic molybdenum complex as well as preparation method and application thereof

A technology of complexes and organic molybdenum, which is applied in the field of sulfur-free phosphorus organic molybdenum complexes and its preparation, can solve the problems that the preparation method has not been reported on a large scale, and achieve the protection of mechanical equipment and the natural environment, good tribological performance, and improved The effect of anti-friction and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Dissolve 5.4 g of 2-hydroxydodecyldiethanolamine (EHDA) in absolute ethanol solution, add 1.6 g molybdenum acetylacetonate MoO 2 (acac) 2 (CAS: 17524-05-9, chemical formula: C 10 h 14 MoO 6 ) (the molar ratio of EHDA and molybdenum acetylacetonate is 2:1), heated at reflux and stirred for 24h at 80°C, the reaction solution turned dark green, terminated the reaction, cooled to room temperature and centrifuged to remove insoluble matter, collected the supernatant Liquid, obtain a kind of blue-green viscous oily paste (double 2-hydroxydodecyldiethanolamine molybdenum complex EHDA-Mo) 6.10g of a sulfur-free phosphorus organomolybdenum complex after decompression spins off solvent, productive rate 82.10 %, of which molybdenum content is 10.03%.

[0048] The above reaction equation:

[0049] R is C 10 h 22 .

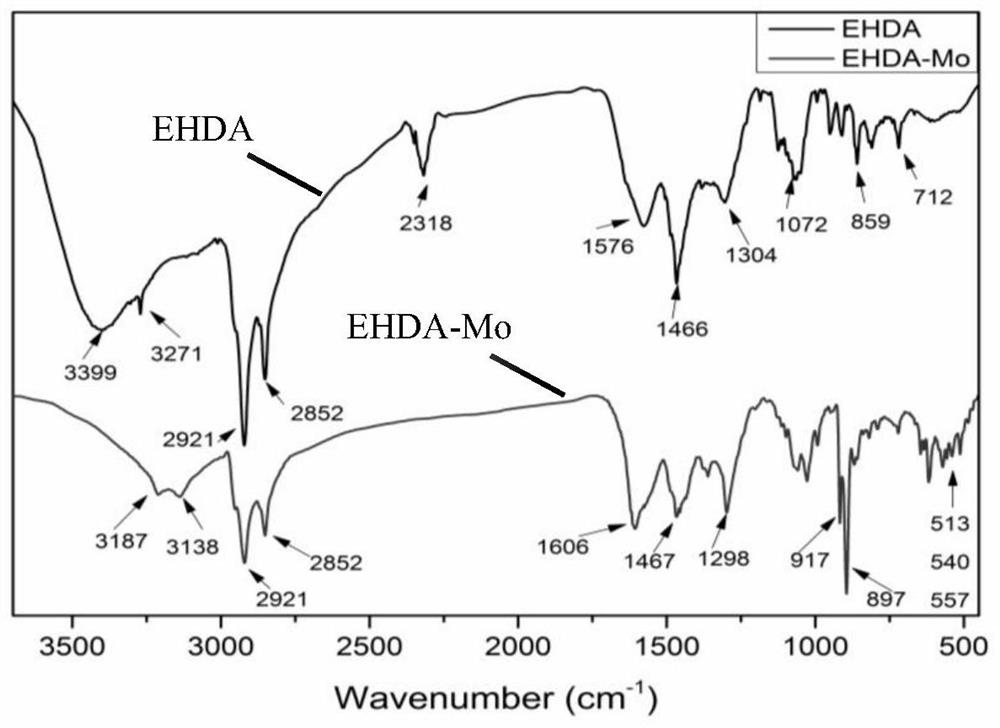

[0050] Implementation Effect: figure 1 It is the infrared spectrum analysis schematic diagram of embodiment 1 product, and analysis result is as follows: IR ...

Embodiment 2

[0052] Dissolve 5.4 g of oleic acid diethanolamine (BODA) in absolute ethanol solution, add 1.6 g of molybdenum acetylacetonate MoO 2 (acac) 22 (The molar ratio of BODA and molybdenum acetylacetonate is 2:1), heated under reflux and stirred for 36h at 80°C, the reaction solution turned dark green, terminated the reaction, cooled to room temperature and centrifuged to remove insoluble matter, and collected the supernatant , obtained a blue-green viscous oily paste (oleic acid diethanolamine molybdenum complex BODA-Mo) 6.26g of a sulfur-free phosphorus organic molybdenum complex after decompression and spin removal of solvent, the productive rate was 76.55%, and wherein the molybdenum content was 9.69% %.

[0053] The above reaction equation:

[0054] R is C 15 h 30

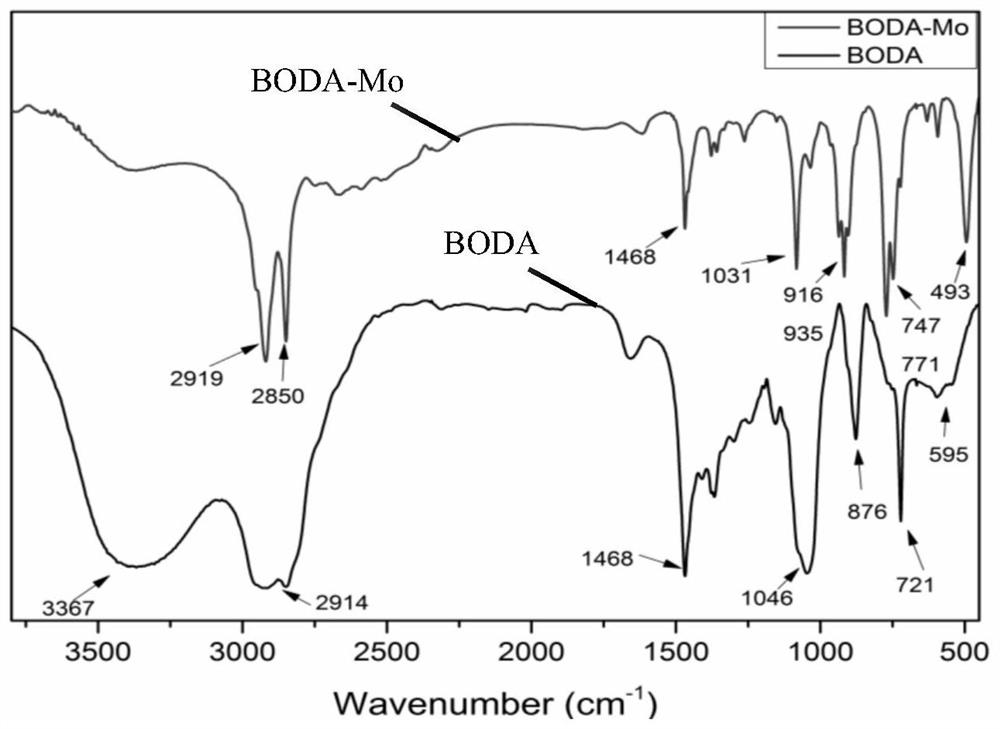

[0055] Implementation Effect: figure 2 It is the infrared spectrum analysis schematic diagram of embodiment 2 product, and analysis result is as follows: IR (cm -1 ): 3187, 3138 (-NH, -OH); 2921, 2852 (-C...

Embodiment 3

[0057] 6.85g of glycerol monooleate (GMO) was dissolved in absolute ethanol solution, and 3.12g of molybdenum acetylacetonate Mo(acac) was added 2 (The molar ratio of GMO and molybdenum acetylacetonate is 2:1), heated at reflux and stirred for 48h at 80°C, centrifuged to remove insolubles after terminating the reaction, collected the supernatant, and decompressed to remove the solvent to obtain a sulfur-free The blue-green viscous oily paste (GMO-Mo) of phosphorus organomolybdenum complex is 8.06g, the yield is 85.33%, and the molybdenum content is 7.68%.

[0058] The above reaction equation:

[0059] R is C 15 h 30

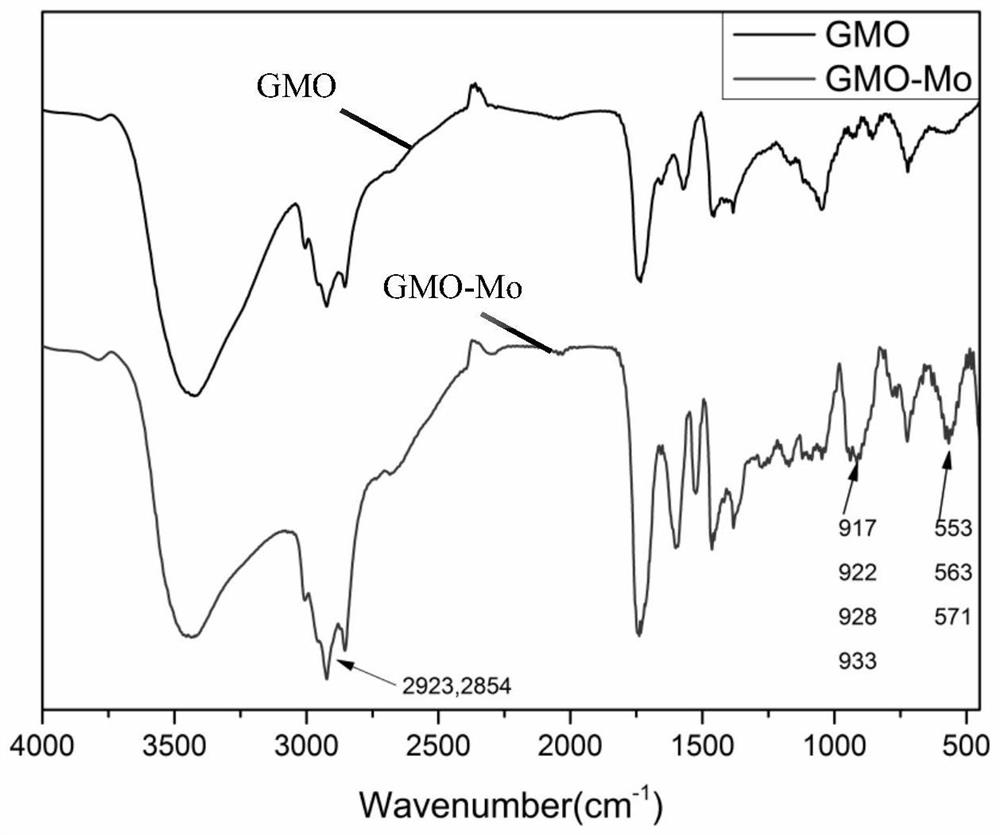

[0060] Implementation Effect: image 3 It is the infrared spectrum analysis schematic diagram of embodiment 3 product, and analysis result is as follows: IR (cm -1 ): 2919, 2850 (-CH 2 -, -CH 3 ); 917,938 (Mo=O); 513,493 (Mo-O), the infrared spectrogram can confirm that the obtained compound is the target compound.

[0061] The ICP test results of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com