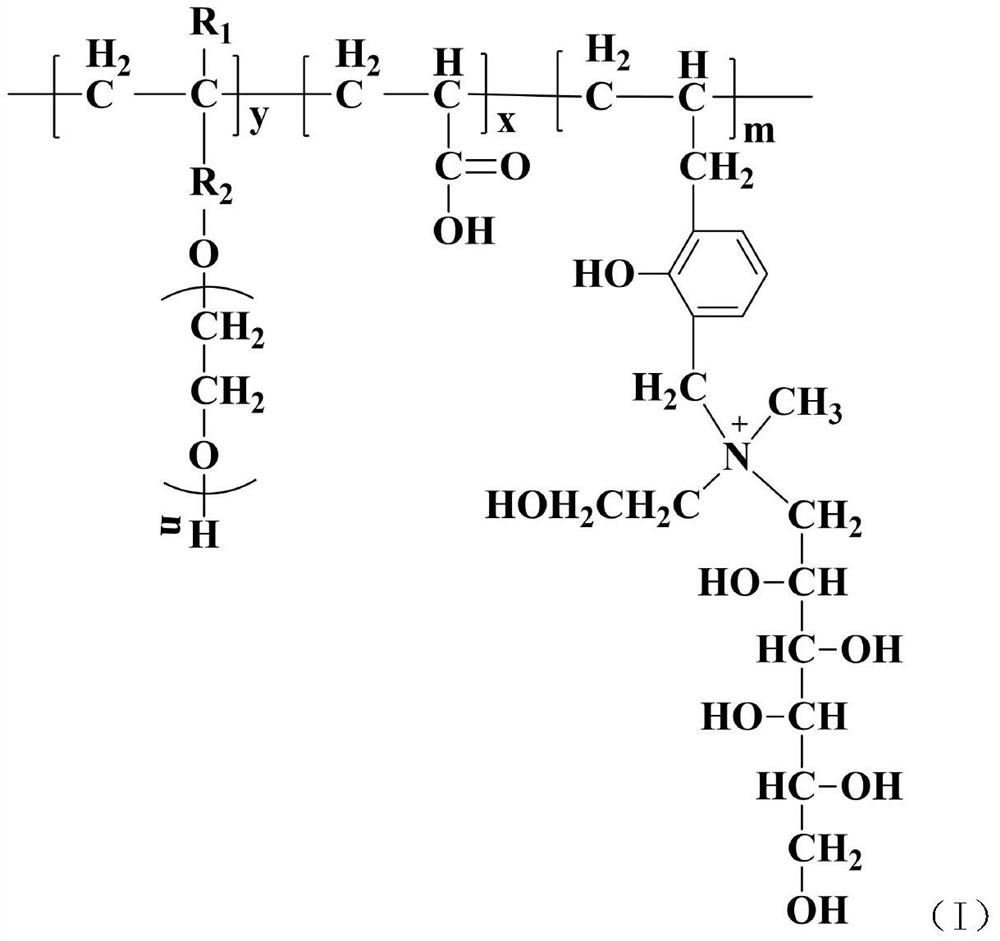

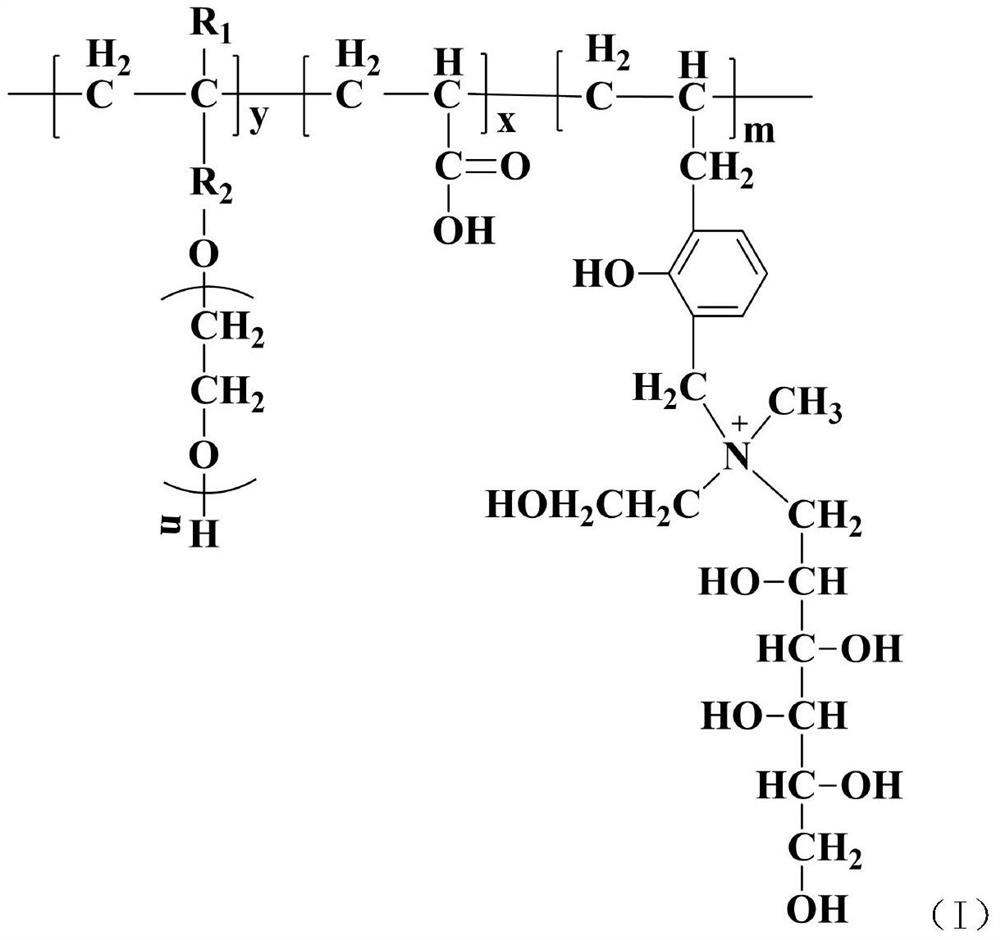

Anti-mud polycarboxylate water reducing agent and preparation method thereof

A polycarboxylic acid, anti-mud type technology, applied in the field of building material admixtures, can solve the problems of insufficient slump retention performance, poor adaptability, segregation and bleeding of concrete, achieve good dispersion and dispersion retention, and improve slump retention performance. , the effect of improving dispersing ability and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

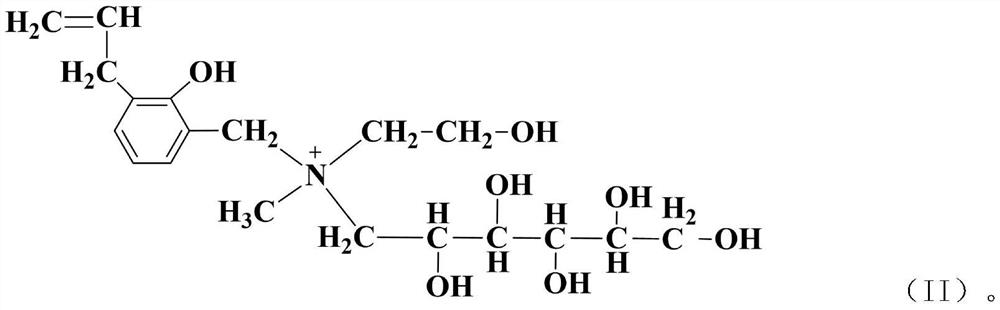

[0020] A preparation method of anti-mud type polycarboxylate water reducer, comprising the following steps:

[0021] Add 250g of water and 300g of polyether macromonomer APEG to a 1000mL four-necked round-bottom flask equipped with a thermometer, an electric stirrer, a constant temperature electric heating mantle, and a peristaltic pump. Then directly add the mixed solution of 3.6g ammonium persulfate and 16g water and stir for 10 minutes to fully dissolve it. Within 3 hours, add dropwise the mixed aqueous solution consisting of 42g of acrylic acid, 10g of glucose-based unsaturated cationic functional monomers, and 72g of water, and the mixed solution of 0.65g of ascorbic acid, 1.5g of mercaptopropionic acid, and 85g of water. The temperature was maintained at 57 Between -60°C; continue to react for 2 hours after the dropwise addition is completed, then cool down to 30-35°C, add 30% sodium hydroxide solution and dilution water to obtain an anti-mud type polymer with a pH of 6-...

Embodiment 2

[0024] A preparation method of anti-mud type polycarboxylate water reducer, comprising the following steps:

[0025] Add 250g of water and 300g of polyether macromonomer HPEG into a 1000mL four-necked round-bottomed flask equipped with a thermometer, an electric stirrer, a constant temperature electric heating mantle, and a peristaltic pump. Then directly add the mixed solution of 3.6g ammonium persulfate and 16g water and stir for 10 minutes to fully dissolve it. Within 3 hours, add dropwise the mixed aqueous solution consisting of 42g of acrylic acid, 10g of glucose-based unsaturated cationic functional monomers, and 72g of water, and the mixed solution of 0.65g of ascorbic acid, 1.5g of mercaptopropionic acid, and 85g of water. The temperature was maintained at 57 Between -60°C; continue to react for 2 hours after the dropwise addition is completed, then cool down to 35-40°C, add 30% sodium hydroxide solution and dilution water to obtain a mud-resistant polymer with a pH of...

Embodiment 3

[0028] A preparation method of anti-mud type polycarboxylate water reducer, comprising the following steps:

[0029] Add 250g of water and 300g of polyether macromonomer TPEG to a 1000mL four-necked round-bottom flask equipped with a thermometer, an electric stirrer, a constant temperature electric heating mantle, and a peristaltic pump. Then directly add the mixed solution of 3.6g ammonium persulfate and 16g water and stir for 10 minutes to fully dissolve it. Within 3 hours, add dropwise the mixed aqueous solution consisting of 42g of acrylic acid, 10g of unsaturated cationic functional monomers containing glucose groups, and 72g of water, and the mixed solution of 0.65g of ascorbic acid, 1.5g of mercaptopropionic acid, and 90g of water, and keep the temperature at 57 Between -60°C; continue to react for 2 hours after the dropwise addition is completed, then cool down to 35-40°C, add 30% sodium hydroxide solution and dilution water to obtain a mud-resistant polymer with a pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com