5G base station protection chip manufacturing process

A technology for protecting chips and manufacturing processes, which is applied in the field of 5G base station protection chip manufacturing processes, and can solve problems such as channel diffusion leakage current and poor chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

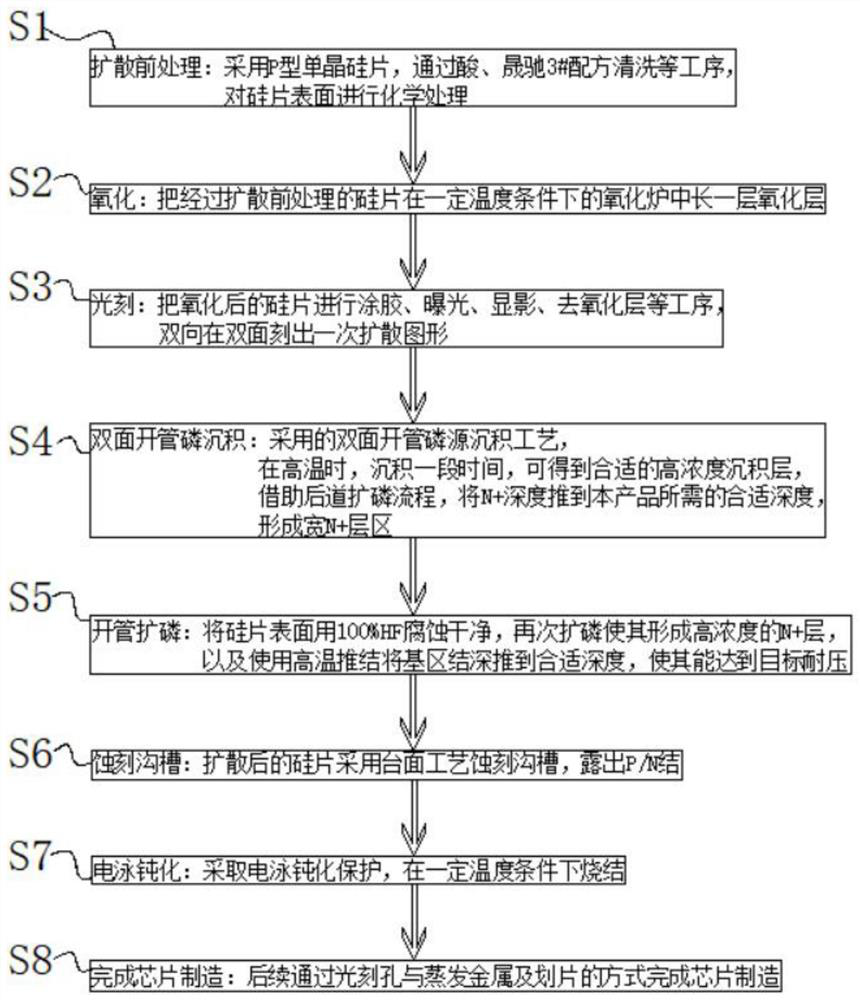

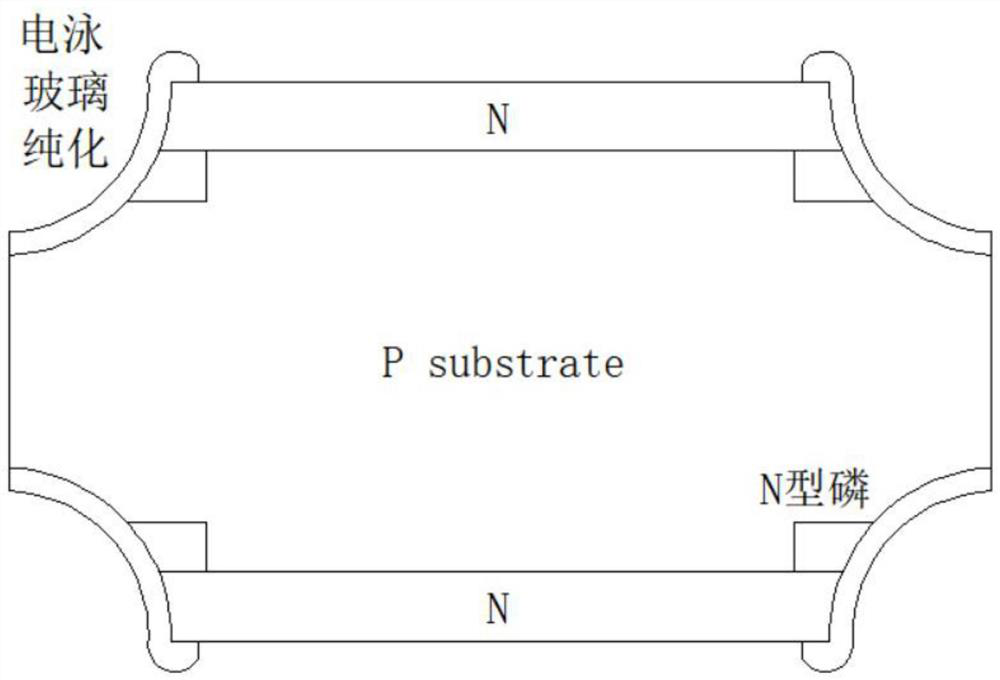

[0025] see Figure 1 to Figure 2 , the present invention provides a technical solution: a 5G base station protection chip manufacturing process, comprising the following steps:

[0026] S1. Pre-diffusion treatment: use P-type single crystal silicon wafers, and carry out chemical treatment on the surface of silicon wafers through processes such as cleaning with acid and Shengchi 3# formula;

[0027] S2. Oxidation: grow a layer of oxide layer on the silicon wafer that has been pre-diffused in an oxidation furnace at a certain temperature;

[0028] S3. Photolithography: apply glue, exposure, development, and deoxidation to the oxidized silicon wafer, and engrave a diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com