Spraying type silver paste for 5G ceramic dielectric filter and preparation method thereof

A ceramic dielectric and filter technology, which is applied in the field of spray-coated silver paste for 5G ceramic dielectric filters and its preparation, can solve problems such as blistering, low quality factor, and weak adhesion of silver film ceramics, and achieve Strong welding force, avoid desoldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

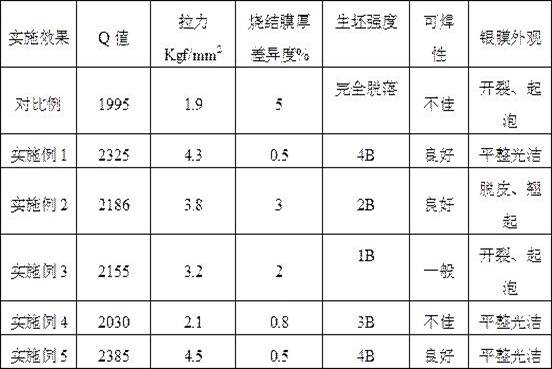

Examples

Embodiment 1~5

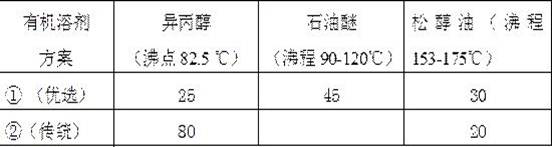

[0024] A spray-on silver paste for 5G ceramic dielectric filter, the silver paste includes the following components in parts by mass: 10 parts of organic binder, 73 parts of silver powder, 2 parts of soldering agent, 1 part of anti-settling agent, and 14 parts of volatile agent. Wherein the organic binder is composed of 20wt% organic resin and 80wt% organic solvent.

[0025] Prepare spray-coated silver paste for 5G ceramic dielectric filter according to the following method

[0026] (1) Preparation of organic binder: based on the total weight of the organic binder as 100, including 20wt% organic resin and 80wt% organic solvent, add the organic resin to the organic solvent and place in a constant temperature water tank at 75°C to 95°C Keep the temperature at medium temperature for 3 hours until the dissolution is complete, and then filter through a 250-325 mesh screen to obtain an organic adhesive.

[0027] (2) Preparation of solder: Mix the metal oxides in the solder, melt at...

Embodiment 6

[0056] A preparation method for spraying silver paste for a 5G ceramic dielectric filter, the method comprising the following steps:

[0057] (1) Material preparation: Prepare materials by weight, 8 parts of organic binder, 82 parts of silver powder, 1.5 parts of soldering agent, 0.5 parts of anti-settling agent, and 12 parts of volatile agent;

[0058] The organic binder includes 8wt% organic resin and 92wt% organic solvent. Among them, the organic resin is a mixed resin composed of hydroxyethyl cellulose, epoxy acrylic resin and dammar resin with a mass ratio of 20:48:16; the organic solvent is butyl carbitol acetate with a mass ratio of 28:42:22 , a mixed organic solvent composed of terpineol and PMA;

[0059] The solder includes the following components in parts by weight: 20 parts of silicon oxide, 5 parts of aluminum oxide, 10 parts of barium oxide, 10 parts of boron oxide, 5 parts of bismuth oxide, 1 part of lithium oxide, 0 parts of zinc oxide, calcium oxide 0 parts,...

Embodiment 7

[0065] A preparation method for spraying silver paste for a 5G ceramic dielectric filter, the method comprising the following steps:

[0066] (1) Material preparation: Prepare materials by weight, 15 parts of organic binder, 68 parts of silver powder, 3.5 parts of soldering agent, 2.0 parts of anti-settling agent, and 15 parts of volatile agent;

[0067]The organic binder includes 30wt% organic resin and 70wt% organic solvent. Among them, the organic resin is a mixed resin composed of hydroxyethyl cellulose, epoxy acrylic resin and dammar resin with a mass ratio of 32:63:24; the organic solvent is butyl carbitol acetate with a mass ratio of 32:48:28 , a mixed organic solvent composed of terpineol and PMA;

[0068] The solder includes the following components by weight: 40 parts of silicon oxide, 15 parts of aluminum oxide, 25 parts of barium oxide, 35 parts of boron oxide, 35 parts of bismuth oxide, 4 parts of lithium oxide, 20 parts of zinc oxide, calcium oxide 15 parts, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com