A laser cladding seven-element high-entropy alloy coating and its preparation method

A high-entropy alloy and laser cladding technology, applied in metal material coating process, coating and other directions, can solve the problem that laser cladding high-entropy alloy coating composition design process parameters are unstable, and the comprehensive performance of the coating cannot be universal. The application, hardness, strength and wear resistance are not ideal, and the cladding layer is uniform and dense, the performance is improved, and the combination is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a seven-element high-entropy alloy coating by laser cladding on a TC4 titanium alloy surface, comprising the following steps:

[0027] (1) The base material titanium alloy (TC 4 ) steel plate wire-cut into a single sample of 52mm×10mm×4mm, polished with 200-mesh and 400-mesh metallographic sandpaper to remove the scale on the surface of the substrate, soaked in 5% NaOH solution for 20min, rinsed with water, took out the sample The sample was placed in an anhydrous ethanol solution for ultrasonic cleaning to remove residual impurities on the surface of the titanium alloy, dried with a hair dryer, and then placed in a 60°C drying oven for drying for 1 hour.

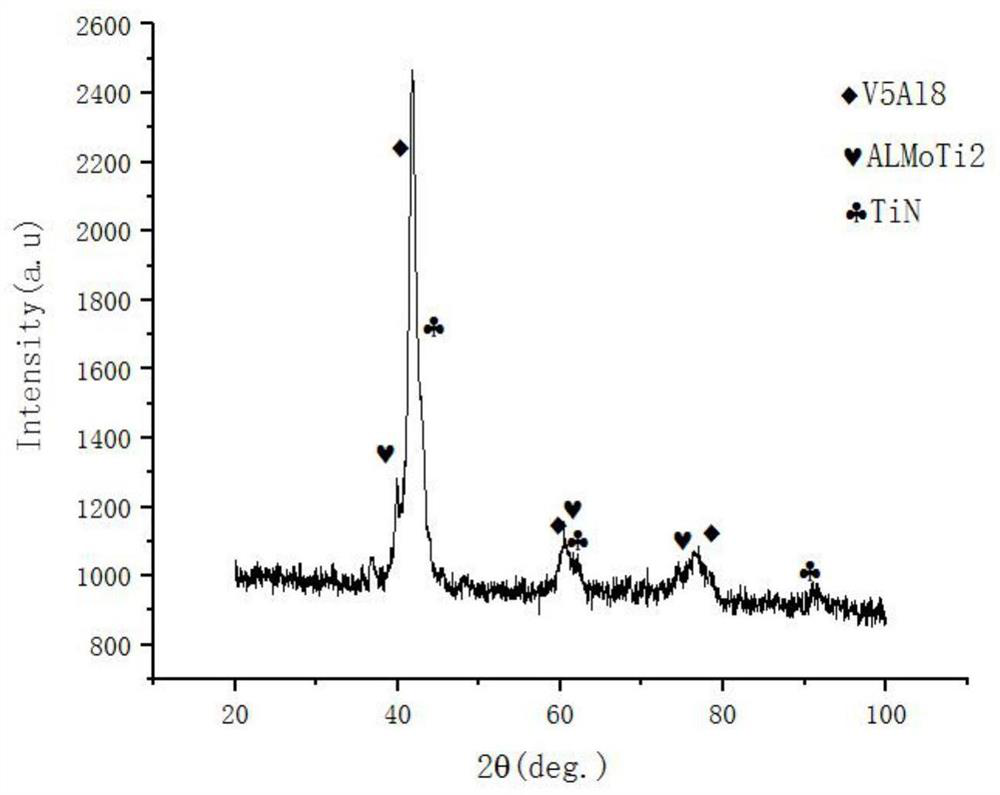

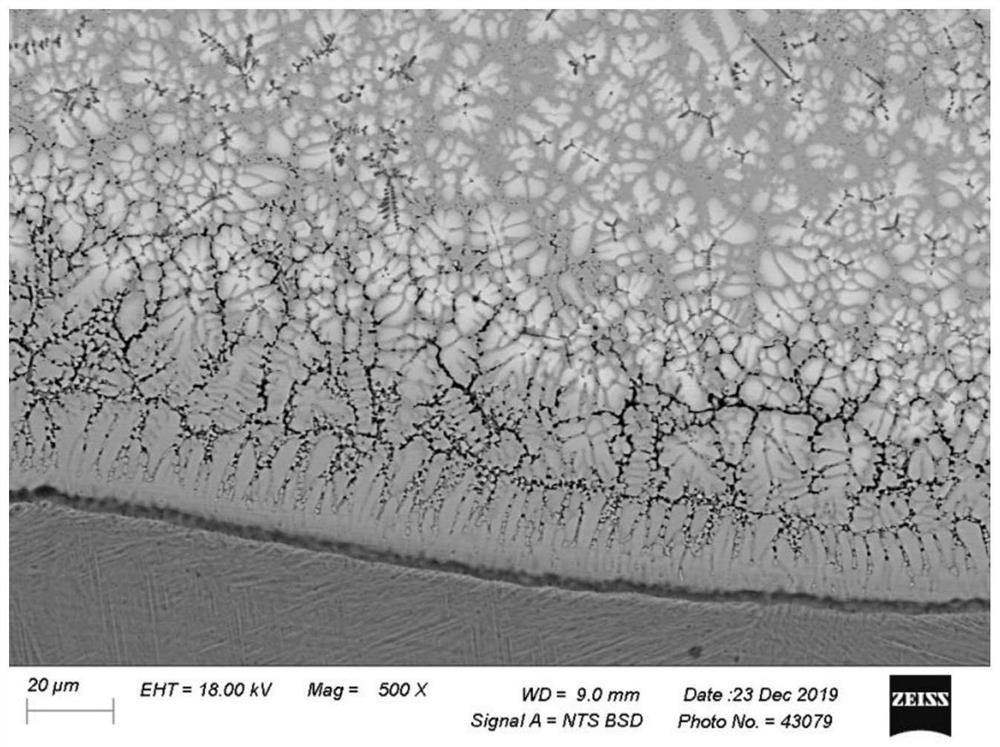

[0028] (2) Al, Co, Cr, Fe, Mo, V, Ti powders with a purity of 99.9% are divided into atomic fractions Al (14.3%), Co (14.3%), Cr (14.3%), Fe (14.3%), After Mo (14.3%), V (14.3%), Ti (14.3%) weighed, carry out ball milling, the parameter of ball milling is ball milling speed 45r / min, ball-mater...

Embodiment 2

[0032] A method for preparing a seven-element high-entropy alloy coating by laser cladding on a TC4 titanium alloy surface, comprising the following steps:

[0033] (1) The base material titanium alloy (TC 4 ) wire cutting into a single piece of 52mm×10mm×4mm sample, and then use 200-mesh and 400-mesh metallographic sandpaper to remove the scale on the surface of the substrate, soak it in NaOH solution with a concentration of 4% for 25min, rinse it with water, and take out the sample Put it in absolute ethanol solution for ultrasonic cleaning to remove residual impurities on the surface of the titanium alloy, blow it dry with a hair dryer, and then put it in a 65°C drying oven for drying. The drying time is 0.8h.

[0034] (2) Al, Co, Cr, Fe, Mo, V, Ti powders with a purity of 99.9% are used according to the mass fraction of Al (15%), Co (11%), Cr (14%), Fe (12%), After weighing Mo (17%), V (15%), T (16%), carry out ball milling, the parameter of ball milling is ball milling s...

Embodiment 3

[0037] A method for preparing a seven-element high-entropy alloy coating by laser cladding on a TC4 titanium alloy surface, comprising the following steps:

[0038] (1) The base material titanium alloy (TC 4 ) wire-cut into a single piece of 52mm×10mm×4mm sample, polished with 200-mesh and 400-mesh metallographic sandpaper to remove the scale on the surface of the substrate, soaked in 6% NaOH solution for 22min, rinsed with water, and took out the sample Put it in absolute ethanol solution for ultrasonic cleaning to remove residual impurities on the surface of the titanium alloy, dry it with a hair dryer, and then put it in a 70°C drying oven for drying. The drying time is 0.6h.

[0039] (2) Al, Co, Cr, Fe, Mo, V, Ti powders with a purity of 99.9% are used according to the mass fraction of Al (16%), Co (14%), Cr (10%), Fe (14%), After Mo (16%), V (15%), T (15%) weighed, carry out ball milling, the parameter of ball milling is ball milling speed 50r / min, ball material ratio 17:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com