High-yield and high-strength cold-drawn deoxidized aluminum bar and processing technology thereof

A cold-drawn deoxidized aluminum bar and processing technology, applied in the field of aluminum bar processing, can solve problems such as hindering further dissolution of aluminum, affecting deoxidation efficiency, affecting aluminum yield, etc., to prevent sputtering, improve deoxidation efficiency, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

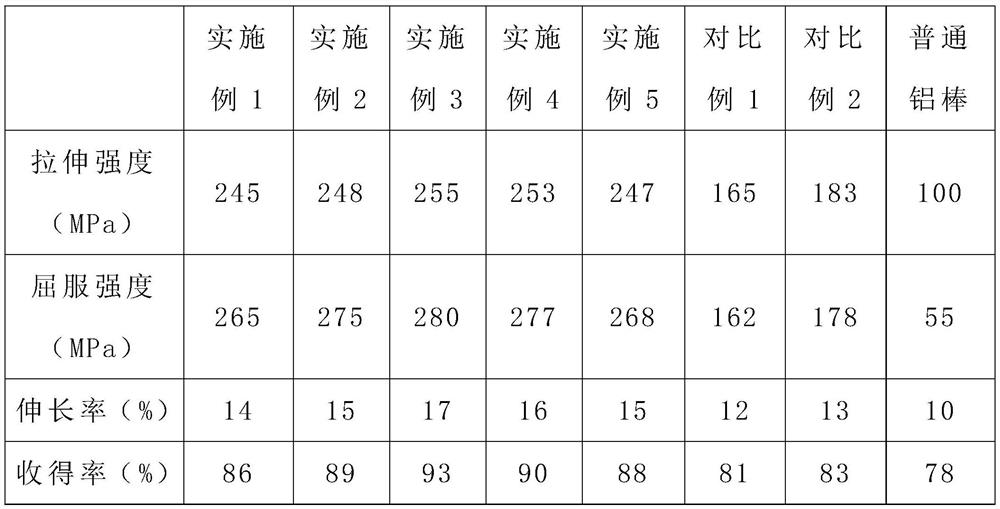

Examples

Embodiment 1

[0067] Take calcium chloride, magnesium chloride, potassium heptafluoroniobate, and silicon oxide for molten electrolysis at a temperature of 710°C, a voltage of 4.3V, and an electrolysis time of 1 hour. After the reaction is completed, an alloy is prepared; preheat the furnace, add aluminum and alloy, and at this time The composition by weight is 9% silicon, 10% calcium, 5% magnesium, and 1% niobium, the temperature is raised to 840° C., and the temperature is kept for 1 hour. 0.4% manganese alloy is added in proportion to the mass, and the temperature is kept for 5 minutes. After removing the slag, the core material A is obtained; Adjust the temperature of the furnace to 720°C, pass in dry argon for refining and degassing, let it stand for 10 minutes, add 0.1% strontium alloy of the core material A as a modification agent, carry out modification treatment, let it stand for 10 minutes, cool down to 680°C, and cast to obtain core material B;

[0068] Take the core material B a...

Embodiment 2

[0071] Take calcium chloride, magnesium chloride, potassium heptafluoroniobate, and silicon oxide for molten electrolysis at a temperature of 715°C, a voltage of 4.4V, and an electrolysis time of 2 hours. After the reaction is completed, an alloy is obtained; preheat the furnace, add aluminum and alloy, and The components are 10% silicon, 11% calcium, 5% magnesium, and 2% niobium. The temperature is raised to 880°C, and the temperature is maintained for 2 hours. 0.5% manganese alloy is added in proportion to the mass, and the temperature is maintained for 5 minutes. After removing the slag, the core material A is obtained; Furnace temperature to 725°C, pass through dry argon for refining and degassing, stand still for 12 minutes, add 0.3% strontium alloy by mass of core material A as a modification agent, carry out modification treatment, stand still for 12 minutes, cool down to 690°C, and cast to obtain the core Material B;

[0072] Take the core material B and heat it to 535...

Embodiment 3

[0075] Take calcium chloride, magnesium chloride, potassium heptafluoroniobate, and silicon oxide for molten electrolysis at a temperature of 720°C, a voltage of 4.5V, and an electrolysis time of 2.5 hours. After the reaction is completed, an alloy is obtained; preheat the furnace, add aluminum, and press The weight components are 11% silicon, 12% calcium, 5% magnesium, and 3% niobium. The temperature is raised to 920 ° C, and the temperature is kept for 3 hours. 0.6% manganese alloy is added according to the mass ratio, and the temperature is kept for 6 minutes. After removing the slag, the core material A is obtained; Adjust the temperature of the furnace to 730°C, pass in dry argon for refining and degassing, let it stand for 15 minutes, add 0.3% strontium alloy of the core material A as a modification agent, carry out modification treatment, let it stand for 15 minutes, cool down to 700°C, and cast to obtain core material B;

[0076] Take the core material B and heat it to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com