Fluorine-containing organic electret agent, preparation method thereof and application of fluorine-containing organic electret agent in electret master batch

An electret, electret technology, applied in separation methods, chemical instruments and methods, rayon manufacturing, etc., can solve problems such as poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

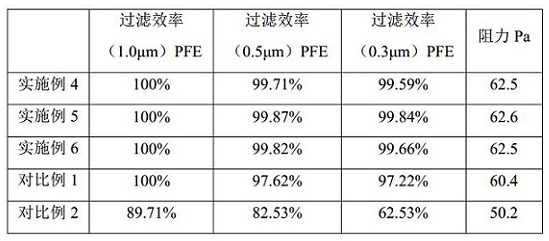

Examples

Embodiment 1

[0033] 1) Preparation of silica particles

[0034] Dissolve 1 g of cetyltrimethylammonium bromide and 50 mL of n-hexane in 100 mL of ethanol solvent, add 50 mL of tetraethyl orthosilicate and 20 mL of ammonia solution under stirring condition, the mass percentage of ammonia solution is 25%, in React at 40°C for 6 hours. After the reaction, centrifuge, wash, dry, and then perform high-temperature roasting. The roasting conditions are: first heat to 260°C at a heating rate of 10°C / min, keep warm for 1h, and then continue to heat at 5°C / min Heating speed to 550°C and holding for 1 hour to prepare silica particles;

[0035] 2) Preparation of electret silica particles

[0036] Put 10g of the silica particles prepared in step 1) into a mixture of 50mL of absolute ethanol and 100mL of deionized water, carry out ultrasonic dispersion, and disperse for 20min; then add 0.1g of silane coupling agent KH-550 to adjust the pH to 5 , stirred and reacted at a constant temperature of 80°C fo...

Embodiment 2

[0040] 1) Preparation of silica particles

[0041]Dissolve 1 g of cetyltrimethylammonium bromide and 100 mL of n-hexane in 300 mL of ethanol solvent, add 200 mL of tetraethyl orthosilicate and 60 mL of ammonia solution under stirring condition, the mass percentage of ammonia solution is 25%. React at 80°C for 3 hours. After the reaction is completed, centrifuge, wash, dry, and then perform high-temperature roasting. The roasting conditions are: first heat to 260°C at a heating rate of 10°C / min, keep warm for 3 hours, and then continue to heat at 5°C / min Heating speed to 550°C, holding temperature for 3 hours, to prepare silica particles;

[0042] 2) Preparation of electret silica particles

[0043] Put 10 g of the silica particles prepared in step 1) into a mixture of 50 mL of absolute ethanol and 200 mL of deionized water, and disperse ultrasonically for 30 minutes; then add silane coupling agent KH-550 to adjust the pH to 4. Stir and react at a constant temperature of 70°C...

Embodiment 3

[0047] 1) Preparation of silica particles

[0048] Dissolve 1 g of cetyltrimethylammonium bromide and 80 mL of n-hexane in 200 mL of ethanol solvent. Under stirring conditions, add 100 mL of tetraethyl orthosilicate and 40 mL of ammonia solution. The mass percentage of ammonia solution is 25%. React at 60°C for 4 hours. After the reaction, centrifuge, wash, dry, and then perform high-temperature roasting. The roasting conditions are: first heat to 260°C at a heating rate of 10°C / min, keep warm for 2 hours, and then continue to heat at 5°C / min Heating speed to 550°C, holding temperature for 2 hours, to prepare silica particles;

[0049] 2) Preparation of electret silica particles

[0050] Put 10g of the silica particles prepared in step 1) into a mixture of 50mL of absolute ethanol and 150mL of deionized water, carry out ultrasonic dispersion, and disperse for 30min; then add silane coupling agent KH-550, adjust the pH to 4, and Stir and react at a constant temperature of 70°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com