Furfural preparation process

A preparation process and furfural technology are applied in the field of furfural preparation technology to achieve the effects of reducing waste water discharge, inhibiting side reactions and enhancing dehydration selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

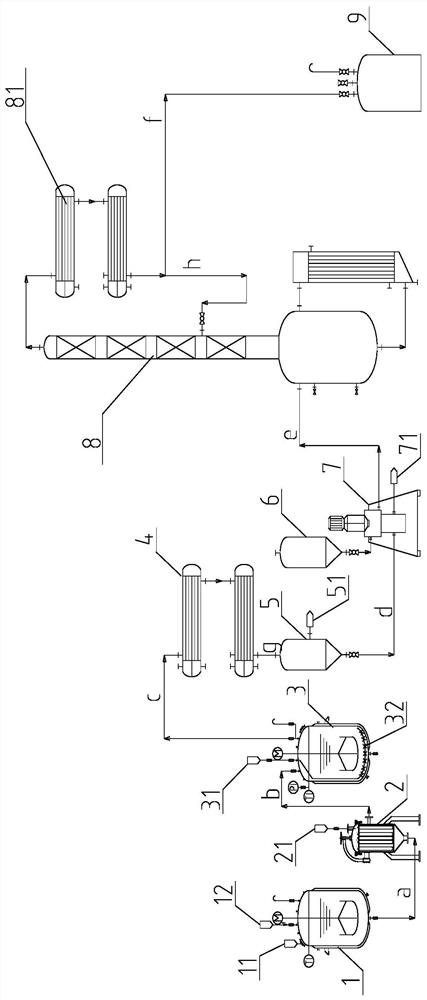

[0031] combine figure 1

[0032] A furfural preparation process device, comprising a hydrolysis reaction kettle 1, the bottom of the hydrolysis reaction kettle 1 is connected to the bottom of the filter 2 through a pipe a, the upper part of the filter 2 is connected to the top of the dehydration reaction kettle 3 through a pipeline b, and the dehydration reaction kettle 3 The top is connected to the inlet of the aldehyde vapor condenser 4 through the pipe c, the outlet of the aldehyde vapor condenser 4 is connected to the stratified tank 5 through the pipe g, and the bottom of the stratified tank 5 is connected to the extraction centrifuge 7 through the pipe d, and the extraction centrifuge 7 The top of the furfural rectification tower is connected to each other by the 8 inlets of the pipeline e, and the upper part of the extraction centrifuge 7 is connected to the lye tank 6 by a pipeline, and the pipeline h is arranged between the top and the bottom of the furfural rectifica...

Embodiment 2

[0041] Adopt the preparation process device of furfural described in embodiment 1, carry out the technique that furfural is prepared, concrete steps are as follows:

[0042] 1) Combine corn cob, SO 4 2- / Fe 2 o 3 -α-Al 2 o 3 The loaded solid acid catalyst is added to the hydrolysis reactor 1 through the solid feed port 11, and the deionized water is passed through the deionized water feed port 12 to hydrolyze the reactor 1, and the temperature and pressure are controlled to start the reaction. After 2 hours of reaction, the reaction solution is Pipeline a enters the catalyst / aldehyde residue filter 2 for filtration, uses nitrogen to dry the filter cake through the first nitrogen inlet 21, and obtains corncob hydrolyzate;

[0043] 2) Add the corn cob hydrolyzate and catalyst obtained in step 1) into the dehydration reactor 3, control the temperature at 160°C and pressure to start the reaction, nitrogen enters the dehydration reactor 3 through the second nitrogen inlet 31, ...

Embodiment 3

[0057] Adopt the preparation process device of furfural described in embodiment 1, carry out the technique that furfural is prepared, concrete steps are as follows:

[0058] 1) Combine corn cob, SO 4 2- / Fe 2 o 3 -α-Al 2 o 3 The supported solid acid catalyst is added to the hydrolysis reactor 1 through the solid feed port 11, and the deionized water is passed through the deionized water feed port 12 to hydrolyze the reactor 1, and the temperature and pressure are controlled to start the reaction. After 2.5 hours of reaction, the reaction The liquid enters the catalyst / aldehyde residue filter 2 from the pipeline a to filter, and uses nitrogen to dry the filter cake through the first nitrogen inlet 21 to obtain the corncob hydrolyzate;

[0059] 2) Add the corncob hydrolyzate and catalyst obtained in step 1) into the dehydration reactor 3, control the temperature at 165°C and pressure to start the reaction, nitrogen enters the dehydration reactor 3 through the second nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com