Preparation method of lysergol

A technology of lysergol and lysergic acid, applied in the field of medicine, can solve the problems of unfriendly environment, low yield of lysergol and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: slough the preparation of the lysergic acid of crystallization water

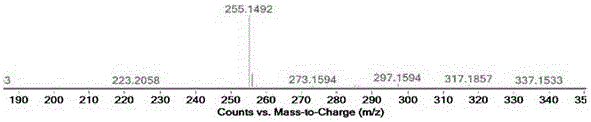

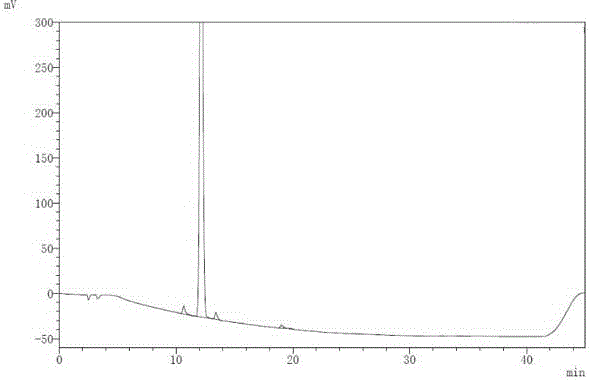

[0061] A mechanical stirrer, a thermometer, a reflux condenser and a nitrogen protection device were installed in a 2L three-necked flask. Add 50g of lysergic acid [purity 97.91%, content (calculated as anhydrous matter) 91.90%] 50g, methanol 1000g and ammonia water 25g into the three-necked bottle, stir to dissolve. Add 10 g of 819-type activated carbon and 100 g of anhydrous sodium sulfate, stir and heat up to reflux. Keep the temperature and stir for 1~2h, filter while it is hot, concentrate the mother liquor under reduced pressure to about 1 / 10 of the original volume, a large amount of solid precipitates, add 100g of methanol, beat at 20~30°C for 1~2h, filter, and filter the cake at 50~60 ℃ and dried under reduced pressure to obtain 35.28 g of lysergic acid with a purity of 99.14% (the HPLC spectrum is attached figure 1 shown), the content (calculated as anhydrous matter) is 98.16...

Embodiment 2

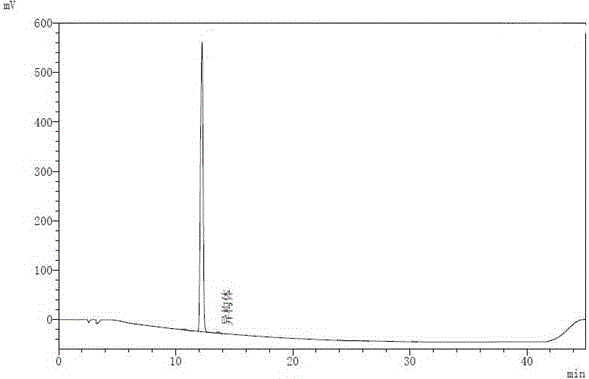

[0062] Embodiment 2: Lysergic acid prepares ergot alcohol

[0063] Install mechanical stirring, thermometer, reflux condenser, drying tube and nitrogen protection device in the 1L three-necked flask. Add 20 g of lysergic acid (purified) and 200 g of pre-dried tetrahydrofuran prepared in Example 1 into the three-necked flask. Stir and lower the temperature to 0~10°C, add 8.50g of lithium aluminum hydride in batches, after the addition, slowly raise the temperature to reflux reaction (reaction liquid temperature 60~70°C). Keep the temperature and stir for 24 hours. After the reaction is complete as monitored by TLC, the temperature is lowered to 0~10°C. Slowly add 200g of 10% ammonium chloride aqueous solution dropwise, after the dropwise addition is complete, continue stirring for 2~3h. Add 10 g of diatomaceous earth and continue stirring for 0.5~1h. Filter and wash the filter cake with tetrahydrofuran / water mixture (20g / 20g). Add 300g of ethyl acetate to the mother liquor,...

Embodiment 3

[0064] Embodiment 3: Lysergic acid prepares ergot alcohol

[0065] Add 2.11g of sodium borohydride and 50g of chloroform into a 250ml three-necked flask, add 5g of decrystallized lysergic acid (purified) prepared in Example 1 under stirring at room temperature, continue stirring for 0.5~1h after adding, slowly add iodine (7.10 g) in chloroform (20 g) solution. After dropping, the temperature was raised to reflux and stirred for 10~15h. After the completion of the reaction was monitored by TLC, the temperature was lowered to 0-10°C. Add 20 g of methanol dropwise, and continue stirring for 3 to 5 hours after the dropwise addition is complete. Add 2g of activated clay and continue stirring for 0.5~1h. Filter, wash the filter cake with chloroform / methanol mixture (15g / 5g), combine the mother liquor, add 30g of water, stir for 5-10min, and separate the liquids. The aqueous phase was extracted twice with chloroform / methanol mixture (30g / 10g). Combine the organic phases, concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com