Method for preparing supported nano-metal material through microwave-assisted carbon template method

A nano-metal, microwave-assisted technology, applied in nanotechnology, nanotechnology, metal processing equipment and other directions, can solve the problems of poor dispersion, serious pollution, and high cost of stencil agents, achieving low cost, simple synthesis route, and huge application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Silicon oxide loaded nano-Ni

[0034] Synthetic raw materials: glucose, urea, silica sol, water, Ni(NO 3 ) 2` 6H 2 O (nickel nitrate)

[0035] (1) Weigh 1.5 g glucose, 2.5 g urea, 2 g silica sol, 5 g water and 0.9 g Ni(NO 3 ) 2 9H 2 O in a 100mL beaker, ultrasonically stirred for 10min until the drug in the beaker was dissolved.

[0036] (2) Take out the molten liquid described in (1), put it into a microwave and heat it with a heating power of 800w, and heat it for 3 minutes to obtain a dark brown puffy solid.

[0037] (3) Grind the sample obtained in (2) with a mortar, put it in a crucible, and bake it in air at 500°C for 5 hours to obtain nano-nickel oxide supported on silicon oxide.

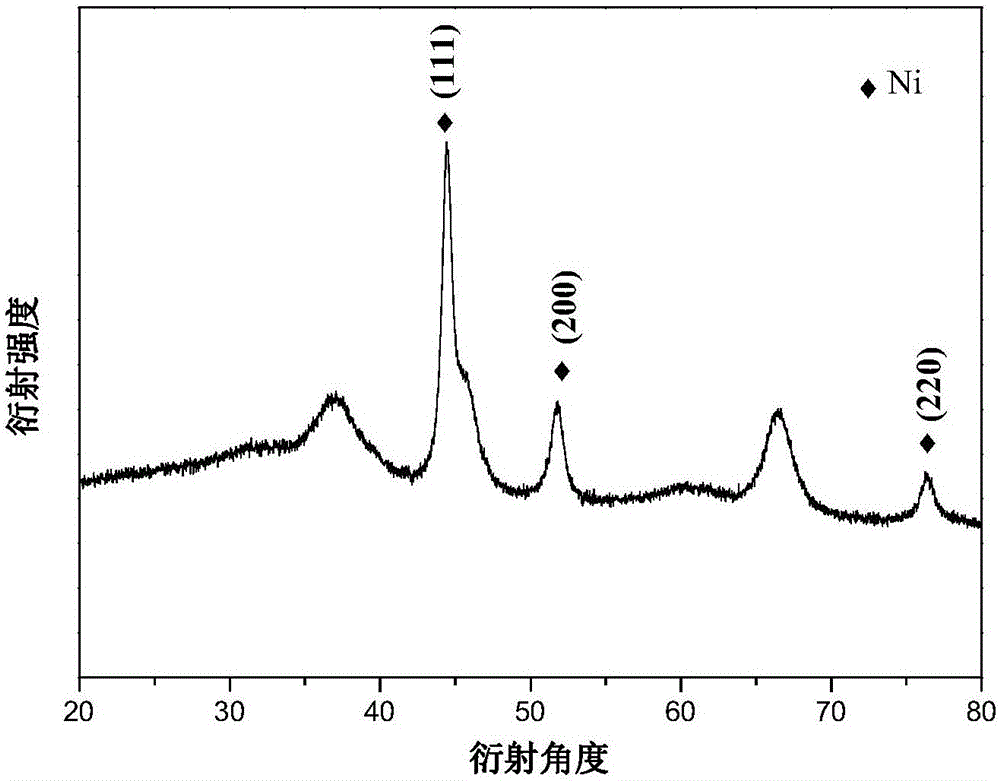

[0038] (4) At 550°C, 5%H 2 / N 2 After heat treatment for 4 h under the same conditions, the silicon oxide-supported nano-metal nickel was obtained, and the XRD test showed that the particle size of Ni was 5 nm.

[0039] figure 1 It is the XRD pattern of metal Ni s...

Embodiment 2

[0040] Example 2: Alumina loaded nano-Ni

[0041] Synthetic raw materials: glucose, urea, aluminum sol, water, Ni(NO 3 ) 2` 6H 2 O (nickel nitrate)

[0042] (1) Weigh 1.5 g glucose, 2.5 g urea, 1 g aluminum sol, 5 g water and 0.9 g Ni(NO 3 ) 2 9H 2 O in a 100mL beaker, ultrasonically stirred for 10min until the drug in the beaker was dissolved.

[0043] (2) Take out the melt described in (1), put it into a microwave and heat it with a heating power of 700w, and heat it for 10 minutes to obtain a dark brown puffy solid.

[0044] (3) Grind the sample obtained in (2) with a mortar, put it in a crucible, and bake it in air at 500°C for 5 hours to obtain nano-nickel oxide supported on alumina.

[0045] (4) At 650°C, 5%H 2 / N 2 After heat treatment for 4 h under the same conditions, the aluminum oxide-supported nano-metal nickel was obtained, and the XRD test showed that the particle size of Ni was 10 nm.

[0046] figure 2 It is the XRD pattern of aluminum oxide loaded n...

Embodiment 3

[0047] Example 3: Lanthanum oxide loaded nano-NiO

[0048] Synthetic raw materials: glucose, urea, lanthanum nitrate, water, Ni(NO 3 ) 2` 6H 2 O (nickel nitrate)

[0049] (1) Weigh 1.5g of glucose, 2.5g of urea, 0.42g of lanthanum nitrate, 5g of water and 0.2g of Ni(NO 3 ) 2 9H 2 O in a 100 mL beaker, ultrasonically stirred for 10 min until the drug in the beaker was dissolved.

[0050] (2) Take out the molten liquid described in (1), put it into a microwave and heat it with a heating power of 700w, and heat it for 5 minutes to obtain a dark brown puffy solid.

[0051] (3) Grind the sample obtained in (2) with a mortar, put it in a crucible, and bake it in air at 500°C for 5 hours to obtain nano-nickel oxide supported by lanthanum oxide.

[0052] image 3 is the XRD pattern of the prepared lanthanum oxide-loaded metal NiO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com