Method for continuously maintaining performance of catalyst for cyclohexene production

A catalyst, cyclohexene technology, applied in the direction of catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of poor catalyst reactivity, unusable use, and rising catalyst unit consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

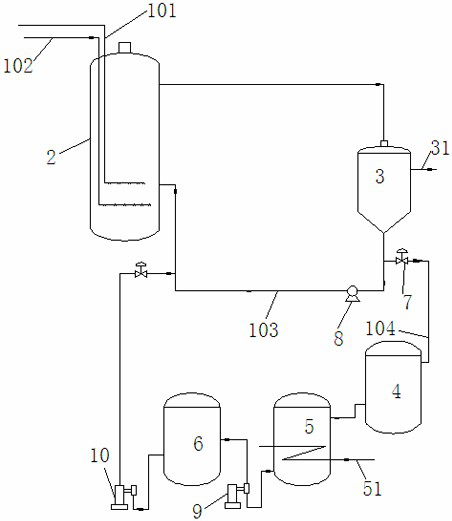

[0038] A method for continuously maintaining catalyst performance for cyclohexene production, the process is as follows:

[0039] (1) Calculate the total amount of catalyst in the benzene hydrogenation reactor:

[0040] M = ρ 催化剂 V 有效

[0041]Reduce the raw material supply of the hydrogenation reactor, reduce the supply of raw material benzene from m t / h to 1 / 2m t / h, and stabilize the system adjustment, discharge the catalyst in the hydrogenation reactor to the catalyst regeneration system, and treat it through the oil removal tank Finally, (the zinc-ruthenium catalyst exists in the zinc sulfate aqueous solution, and circulates with the catalyst in the hydrogenation reaction system, and a certain amount of high-purity water is added to the system during the catalyst discharge process to maintain a certain slurry interface to prevent the interface from being too low. Oil, affecting the reactivity), drained from the oil removal tank, if the 1 / 2M catalyst is drained out, to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com