Silver-iron oxide composite structure film and preparation method and application thereof

A technology of iron oxide and composite structure, which is applied in the direction of structural parts, photosensitive equipment, electrolytic capacitors, etc., can solve the problems of difficult powder dispersion, uneven coating, and weak adhesion, etc., to achieve firm adhesion, uniform membrane electrodes, Pore structure maintains good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

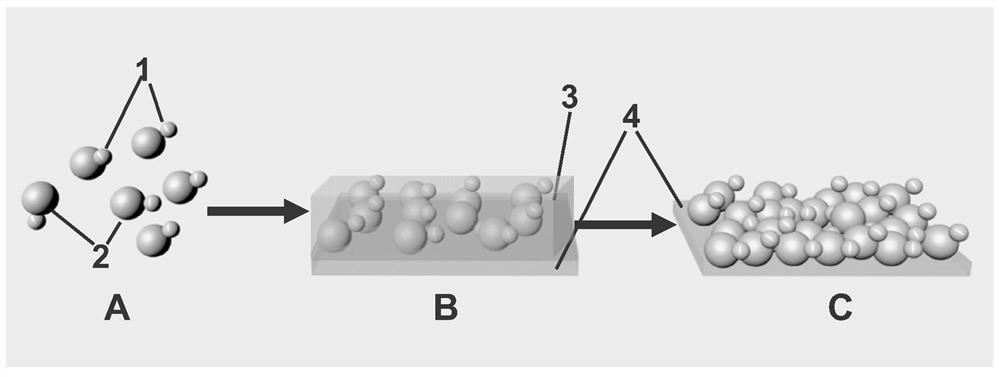

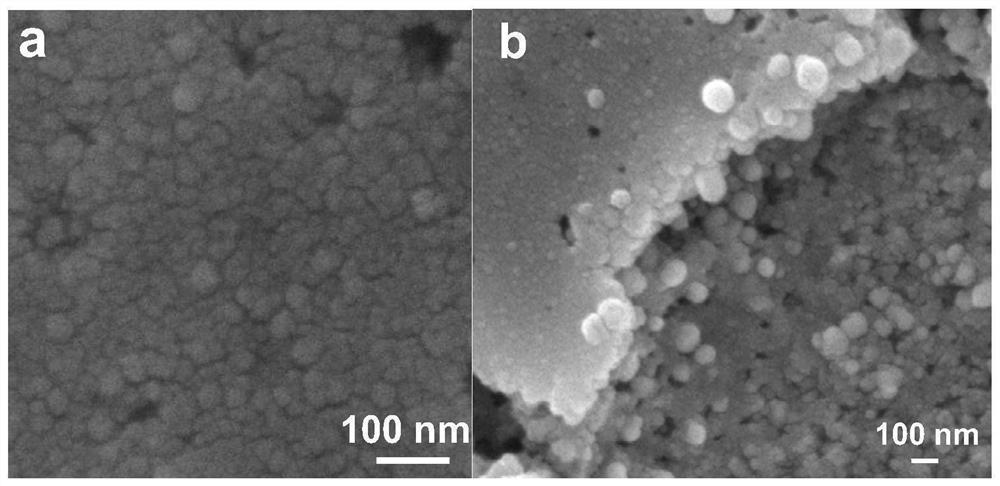

[0022] Firstly, silver-iron oxide composite particles are prepared by condensation reflux method, and then the particles are dispersed in PU glue binder to make slurry, and then coated on the substrate by drop coating method to obtain a thin film. Follow the steps below:

[0023] (1) Add 5, 6, 7, 8, 9, 10mL of dodecanol, 1mL of oleic acid and 1mL of oleylamine to the reaction vessel in turn, heat to 220°C under magnetic stirring, connect the reaction vessel to a condenser tube, and proceed to the heating process Zhongtong condensate return;

[0024] (2) When the temperature rises to 220°C, add 100mg of silver acetate, keep it warm for 1 hour, and then drop the temperature to 150°C;

[0025] (3), add 250mg iron acetylacetonate, keep warm for 1 hour, then rise to 160°C, keep warm for 1 hour;

[0026] (4), the solution was cooled to room temperature, poured ethanol and n-hexane mixed solution with a volume ratio of 4:1 into the reactant, centrifuged and washed 3 times, and coll...

Embodiment 2

[0043] (1) Add 10mL dodecanol, 0.5, 0.6, 0.7, 0.8, 0.9, 1mL oleic acid and 1mL oleylamine to the reaction vessel in turn, heat to 220°C under magnetic stirring, connect the reaction vessel to a spherical condenser, and heat During the process, the condensed water is refluxed;

[0044] Steps (2)~(4) are with embodiment 1;

[0045] (5), transfer the collected precipitate to a blast drying oven, and dry at 60°C for 8 hours to obtain the silver-iron oxide composite particles prepared by adding different volumes of oleic acid in step (1);

[0046] Steps (6)~(13) are the same as in Example 1;

[0047] (14), after the calcination is completed, the tube furnace is cooled to room temperature, the sample is taken out, and finally the silver-iron oxide composite particles prepared by adding different volumes of oleic acid are attached to the silver-iron oxide composite particles formed on the conductive glass substrate. Oxide composite structure film.

Embodiment 3

[0049] (1) Add 10mL dodecanol, 1mL oleic acid and 0.5, 0.6, 0.7, 0.8, 0.9, 1mL oleylamine to the reaction vessel in turn, heat to 220°C under magnetic stirring, connect the reaction vessel to a spherical condenser, and heat During the process, the condensed water is refluxed;

[0050] Steps (2)~(4) are with embodiment 1;

[0051] (5) Transfer the collected precipitate to an air blast drying oven, and dry at 60° C. for 8 hours to obtain silver-iron oxide composite particles prepared by adding different volumes of oleylamine in step (1).

[0052] Steps (6)~(13) are the same as in Example 1;

[0053] (14) After the calcination is completed, the tube furnace is cooled to room temperature, the sample is taken out, and finally the silver-iron oxide composite particles prepared by adding different volumes of oleylamine are attached to the silver-iron oxide composite particles formed on the conductive glass substrate. Oxide composite structure film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com