A kind of preparation method and application of double hemispherical W zeolite

A hemispherical, zeolite technology, applied in chemical instruments and methods, inorganic chemistry, seawater treatment, etc., can solve the problems of uneven zeolite morphology, high energy consumption, high temperature, low cost, good crystallinity, and time-consuming short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 8.42g of potassium hydroxide and 1.22g of sodium aluminate and put them into a glass container respectively, then add 57.80g of deionized water, heat and stir to dissolve the raw materials completely, and make solution A;

[0028] (2) Weigh 10.28g of silica sol, slowly add the silica sol into solution A under stirring, and continue stirring for 0.5h after the addition to form a silica-alumina gel mixture;

[0029] (3) Transfer the above-mentioned silica-alumina gel mixture to a stainless steel synthesis kettle with a polytetrafluoroethylene liner, seal it, place it in an oven, set the oven temperature to 90°C, and crystallize for 48 hours;

[0030] (4) After the reaction is completed, take out the synthesis kettle, filter the reaction mixture with suction, and wash the filter cake with deionized water until the pH of the washing solution reaches 8-9;

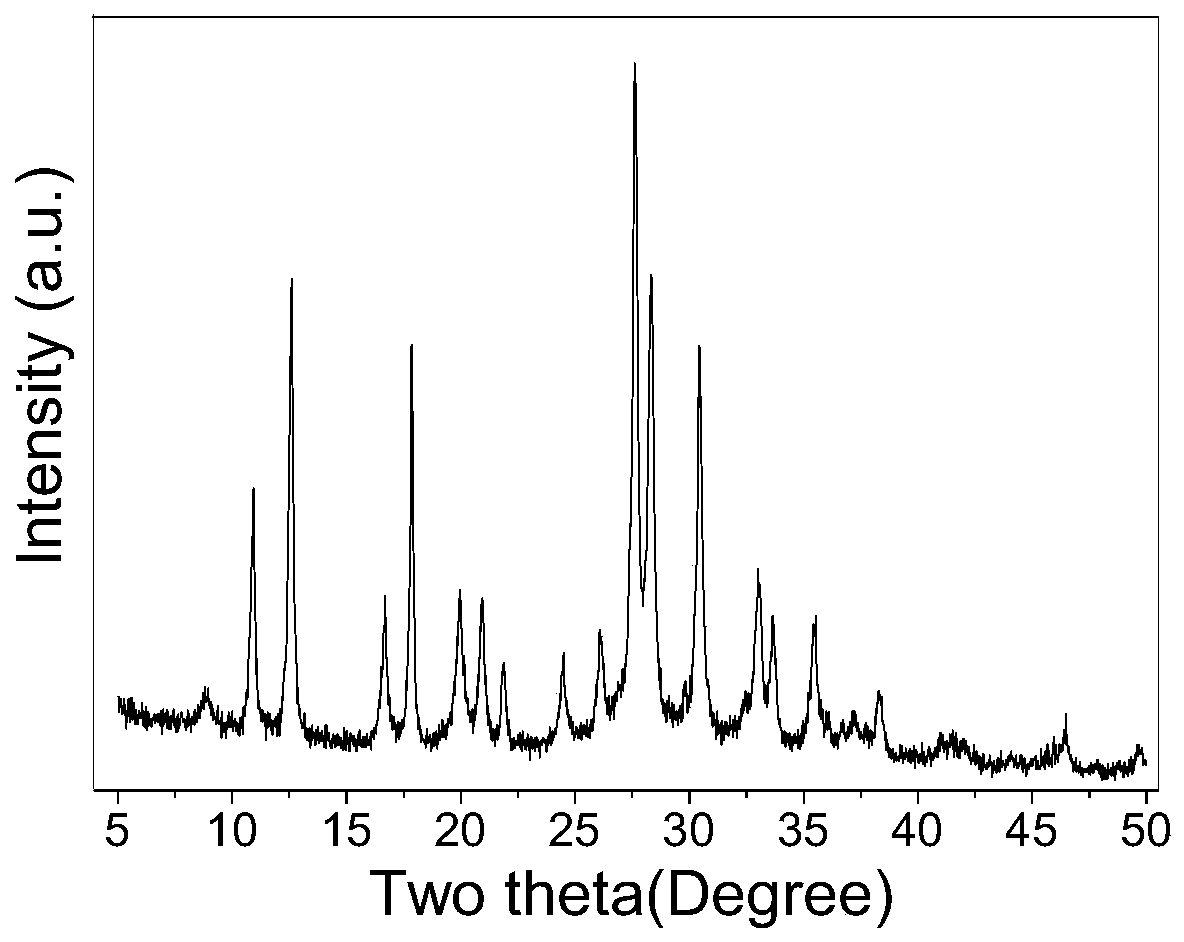

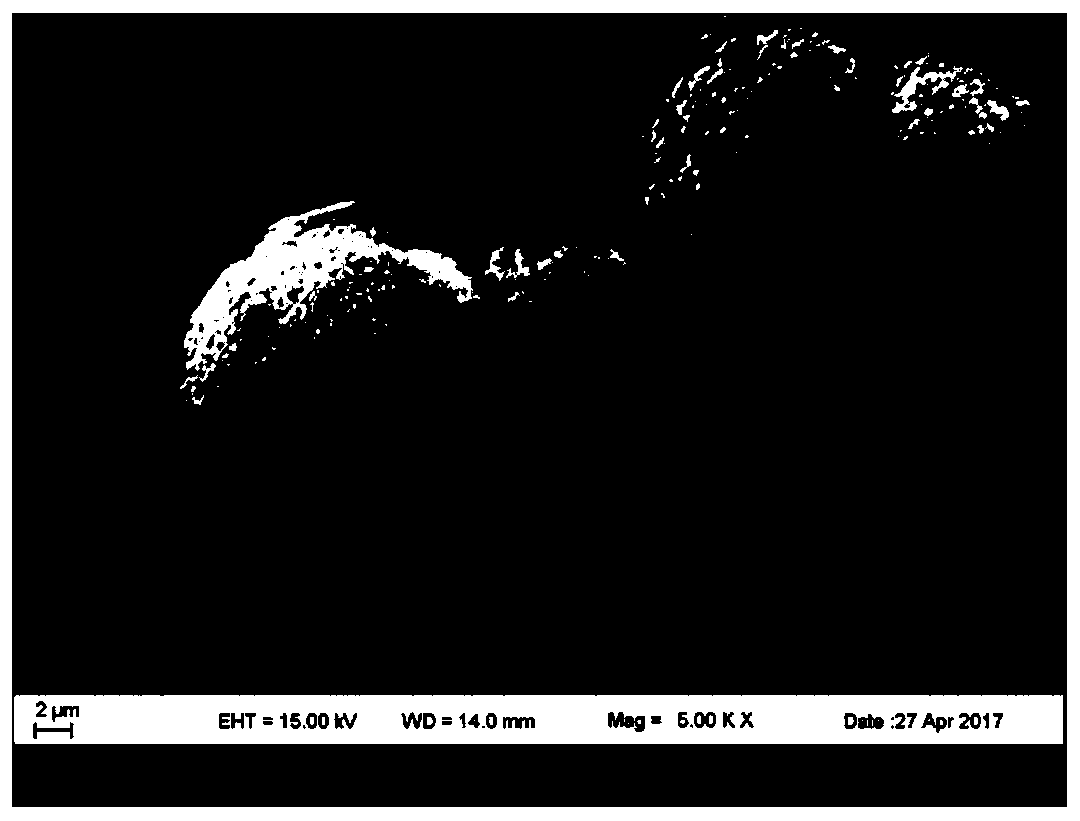

[0031] (5) drying the filter cake at 100°C for 24 hours to obtain the double hemispherical W zeolite of the p...

Embodiment 2

[0036] (1) Take by weighing 8.98g of potassium hydroxide and 0.78g of aluminum hydroxide and put them into a glass container respectively, then add 65.24g of deionized water, heat and stir to dissolve the raw materials completely, and make solution A;

[0037] (2) Weigh 11.34g of silica sol, slowly add the silica sol to solution A under stirring, and continue stirring for 0.5h after the addition to form a silica-alumina gel mixture;

[0038] (3) Transfer the above-mentioned silica-alumina gel mixture to a stainless steel synthesis kettle with a polytetrafluoroethylene liner, seal it, place it in an oven, set the oven temperature to 90°C, and crystallize for 48 hours;

[0039] (4) After the reaction is completed, take out the synthesis kettle, filter the reaction mixture with suction, and wash the filter cake with deionized water until the pH of the washing solution reaches 8-9;

[0040] (5) drying the filter cake at 100°C for 24 hours to obtain the double hemispherical W zeoli...

Embodiment 3

[0043] (1) Take 9.78g of potassium hydroxide and 3.22g of aluminum sulfate and put them into a glass container respectively, then add 65.56g of deionized water, heat and stir to dissolve the raw materials completely, and make solution A;

[0044] (2) Weigh 12.30 g of silica sol, slowly add the silica sol to solution A under stirring, and continue stirring for 0.5 h after the addition to form a silica-alumina gel mixture;

[0045] (3) Transfer the above-mentioned silica-alumina gel mixture to a stainless steel synthesis kettle with a polytetrafluoroethylene liner, seal it, place it in an oven, set the oven temperature to 90°C, and crystallize for 48 hours;

[0046] (4) After the reaction is completed, take out the synthesis kettle, filter the reaction mixture with suction, and wash the filter cake with deionized water until the pH of the washing solution reaches 8-9;

[0047] (5) drying the filter cake at 100°C for 24 hours to obtain the double hemispherical W zeolite of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com