Horseshoe processing and preparation method

A horseshoe and round steel technology, applied in metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem that round steel is prone to offset during stamping and forming, inconvenient to bend round steel, fixed and clamped, and cannot ensure level Stability and other issues, to avoid offset, easy to fix and clamp, good bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

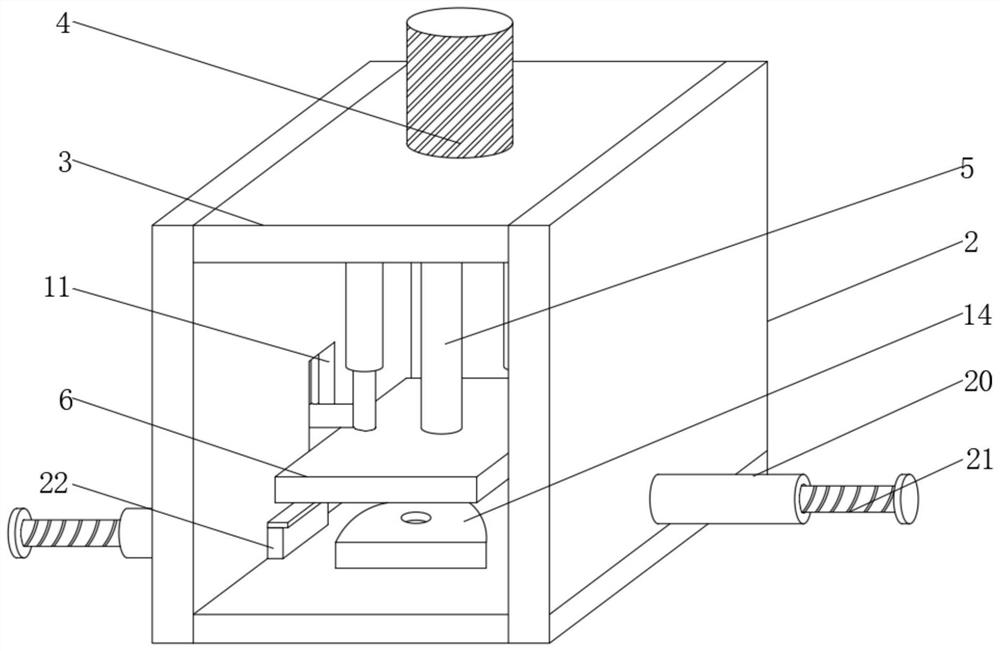

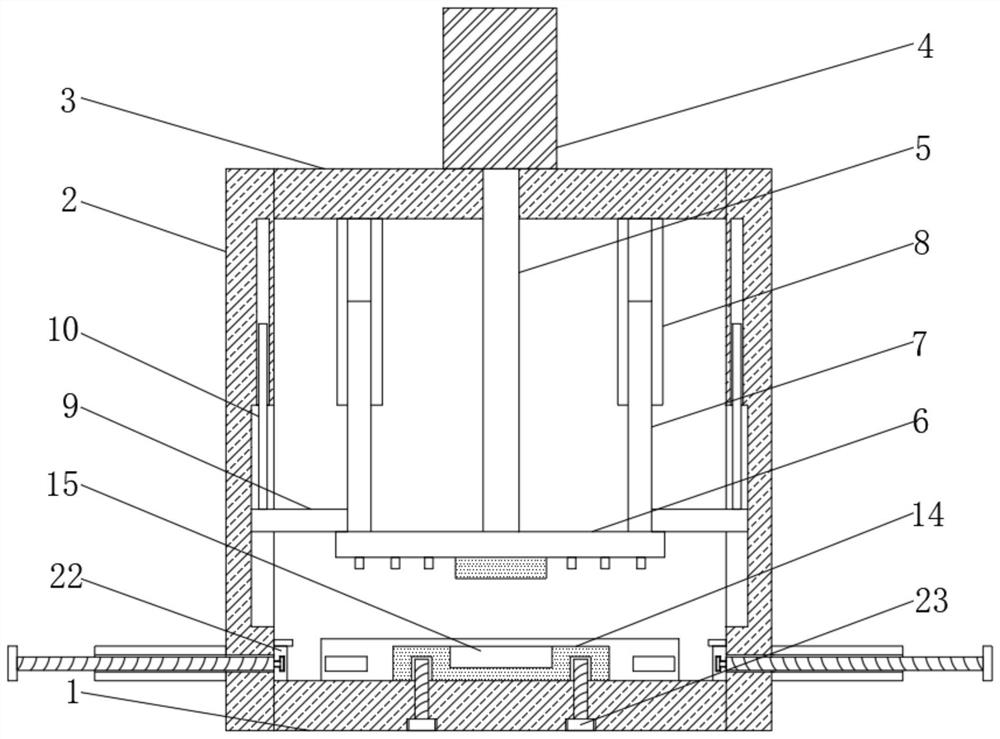

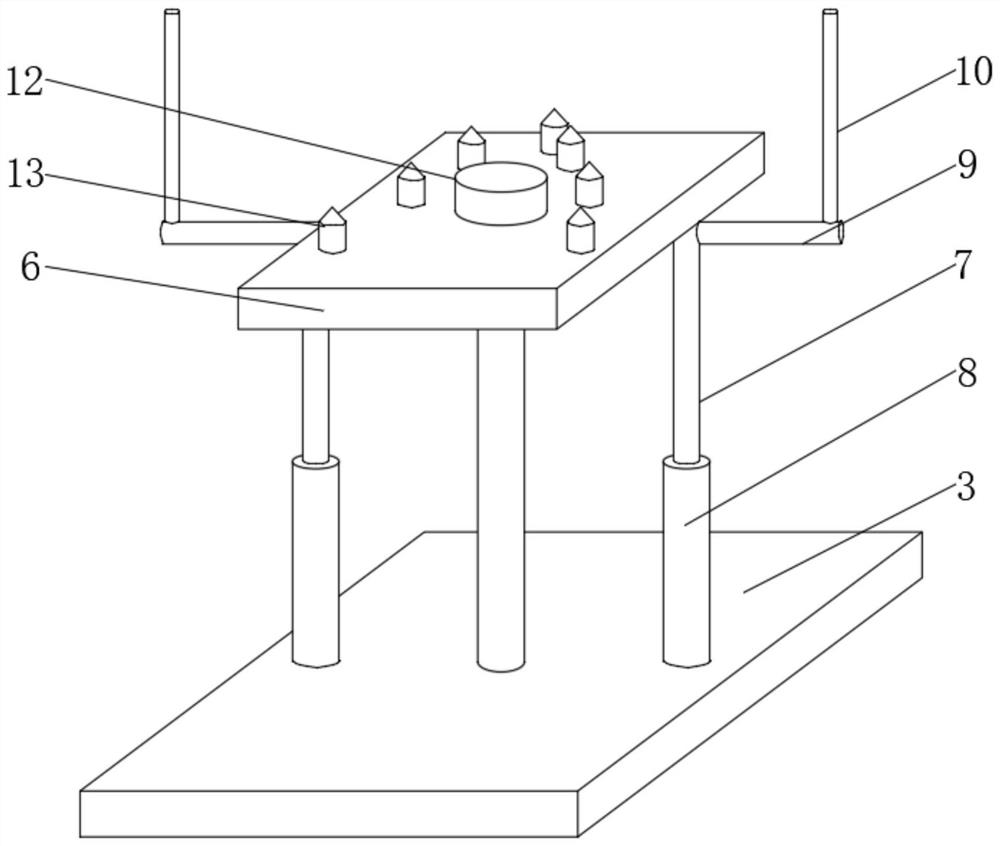

[0029] The processing and preparation method of horseshoe includes a base plate 1, and the specific steps are as follows:

[0030] Step 1: Prepare the raw materials: After selecting the intact round steel, cut the round steel to the required length with a cutting tool, and remove the dust and debris on the round steel;

[0031] Step 2: pretreatment of blanking: put the round steel obtained in step 1 into the intermediate frequency furnace, and make the internal temperature of the intermediate frequency furnace reach 1050 degrees;

[0032] Step 3: pressure forming: the round steel heated in step 2 is made into a blank by a punching machine, and placed on the bottom plate 1 in the pressure forming device for punching forming, so that the round steel is punched into the shape of a horseshoe;

[0033] Step 4: Punch slicing: After the horseshoe after stamping in step 3 is cooled, place the horseshoe on the punch to clamp, and slice the horseshoe, so that the horseshoe is sliced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com