Construction method of large-diameter rain sewage pipeline assembling type component structure

A construction method and technology of component structure, which are applied in the sewer system, waterway system, water supply device, etc., can solve the problems of long concrete construction period, easy damage of the pipe body, and pipe deviation, and improve the bearing capacity and stability of the foundation. , Enhance the integrity of the installation and reduce the effect of later settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this embodiment, the construction technical requirements for the excavation of pipe grooves, the construction process requirements for solidified soil, and the ratio of cement grouting will not be described in detail, and the implementation of the construction of the assembled component structure of the large-diameter rainwater and sewage pipelines and sewage pipelines involved in the present invention will be focused on Way.

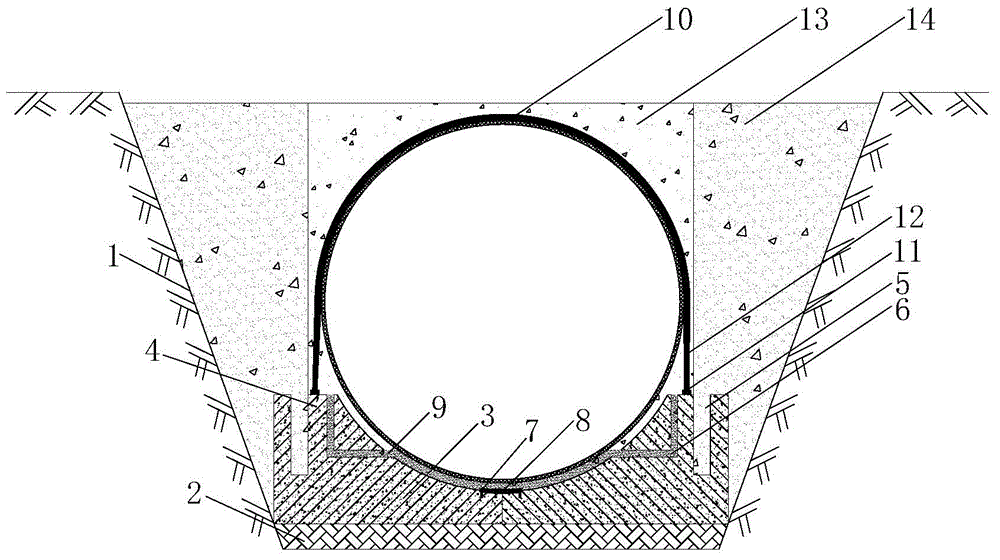

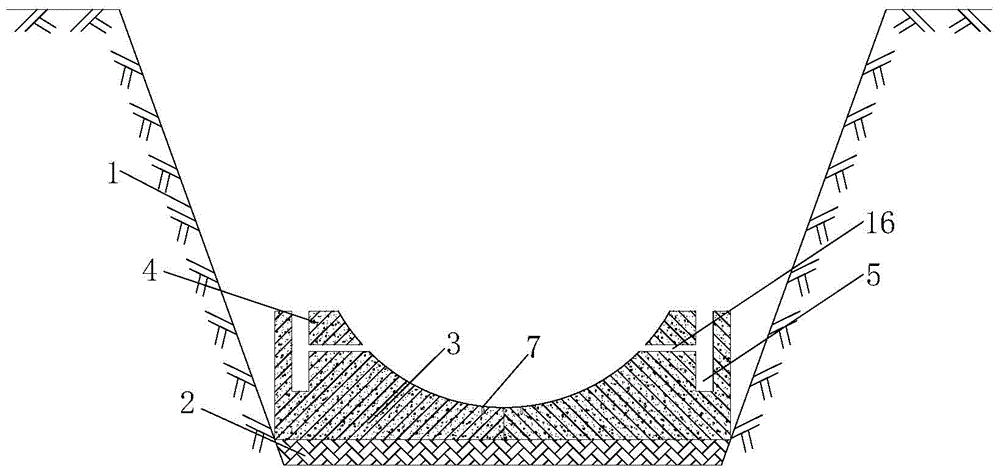

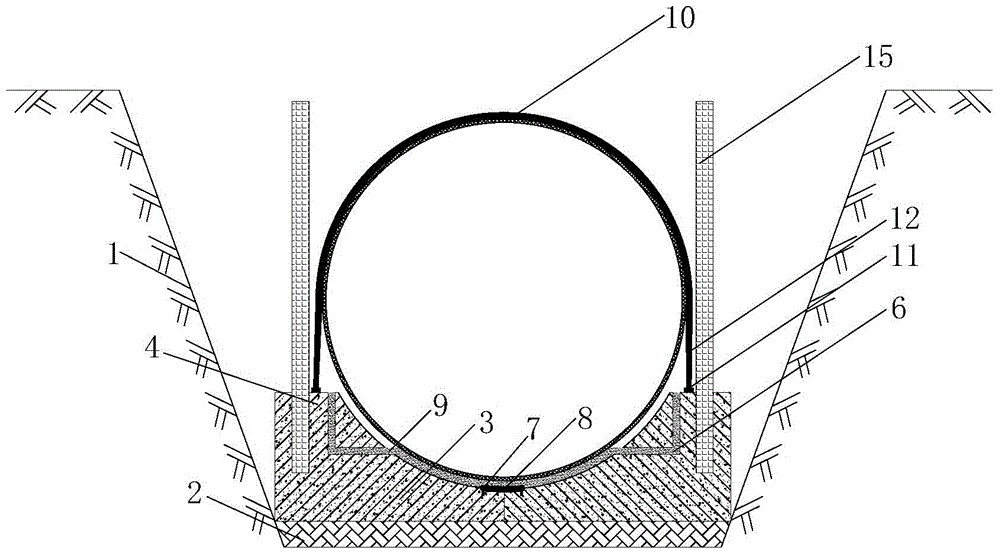

[0034] figure 1 It is a structural schematic diagram of the large-caliber rainwater and sewage pipeline assembly type component of the present invention, figure 2 It is a schematic diagram of the connection of the symmetrical double-split pipeline base in the present invention, image 3 It is a schematic diagram of concrete backfill formwork in the present invention. refer to figure 1 The assembly structure of the large-diameter rainwater and sewage pipes and sewage pipes shown is mainly composed of the pipe base padding part 3, the pipe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com