Denitration catalyst, and preparation method and application thereof

A denitration catalyst and denitration technology, applied in the field of denitration catalysts, can solve the problems of high reaction temperature, easy to cause toxicity, environmental pollution in the preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

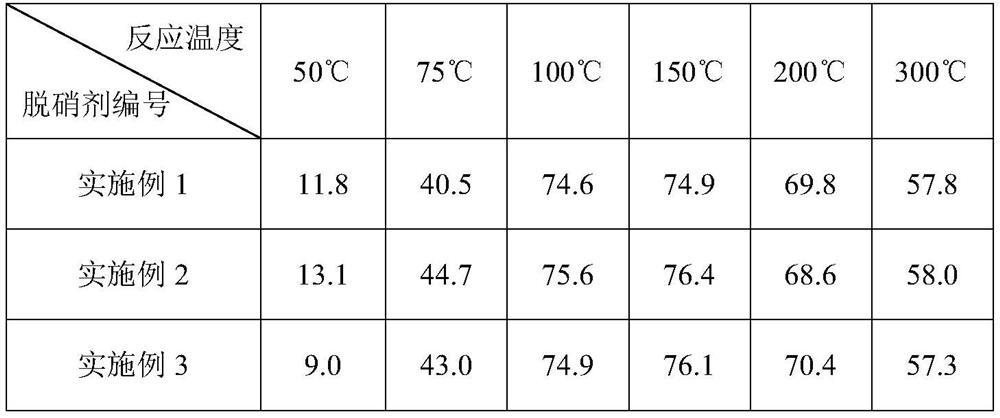

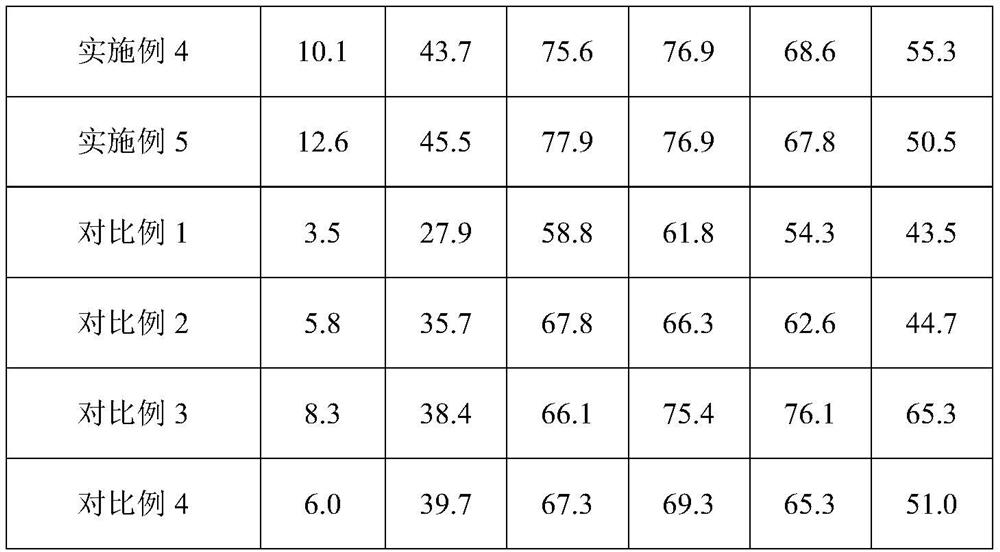

Examples

preparation example Construction

[0029] In some optional embodiments, the preparation method includes: according to the above parts by weight, the product obtained by mixing all the components is dried, roasted, cooled to room temperature, ground and sieved.

[0030] Preferably, the method includes allowing the mixture of all components to stand still for 6-12 hours, and then drying the block or ball through an extruder or a special mold.

[0031] Preferably, the prepared block or sphere is uniform in size, and its side length or diameter is not more than 0.5 cm, so as to avoid the uneven distribution of internal pores caused by the uneven heating of the catalyst in the subsequent drying and roasting process, thereby reducing the activity of the catalyst .

[0032] Preferably, the drying condition is 90-150° C. for 2-6 hours.

[0033] Preferably, the calcination condition is 300-600° C. for 2-5 hours.

[0034] Preferably, after grinding, pass through a 40-80 mesh sieve, that is, grind to 0.2mm-0.425mm.

[...

Embodiment 1

[0046] This embodiment provides a method for preparing a denitration catalyst, which includes the following steps.

[0047] (1) Raw material components:

[0048] 65.0g red mud, 27.0g CFB coal-fired boiler fly ash, 5.2g general formula CeMn 0.8 co 0.2 o 3 perovskite composite metal oxide and 2.8g pore expander.

[0049] (2) Preparation:

[0050] Prepare according to the above parts by weight. First, the red mud and fly ash are crushed separately, dried to constant weight, and mechanically stirred until uniformly mixed to obtain a mixture of red mud and fly ash.

[0051] Put the perovskite-type composite metal oxide in a beaker, add 300mL of distilled water, heat and stir in a water bath at 35°C for 120 minutes, then slowly add the mixture of red mud and fly ash into the beaker, and continue heating and stirring in the water bath after the addition is complete 15min. After stirring, add the pore-enlarging agent into the beaker. After the addition, continue heating and sti...

Embodiment 2

[0054] This embodiment provides a method for preparing a denitration catalyst, which includes the following steps.

[0055] (1) Raw material components:

[0056] 62.0g red mud, 21.0g CFB coal-fired boiler fly ash, 13.5g general formula CeMn 0.5 co 0.5 o 3 perovskite composite metal oxide and 3.5g pore expander.

[0057] (2) Preparation:

[0058] Prepare according to the above parts by weight. First, the red mud and fly ash are crushed separately, dried to constant weight, and mechanically stirred until uniformly mixed to obtain a mixture of red mud and fly ash.

[0059] Put the perovskite-type composite metal oxide in a beaker, add 300mL of distilled water, heat and stir in a water bath at 50°C for 85 minutes, then slowly add the mixture of red mud and fly ash into the beaker, and continue heating and stirring in the water bath after the addition is complete 15min. After stirring, add the pore-enlarging agent into the beaker. After the addition, continue heating and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com