Amorphous porous silicon dioxide coated Pt/C catalyst and preparation method thereof

A porous silica and amorphous technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of poor activity and stability of Pt/C catalyst question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

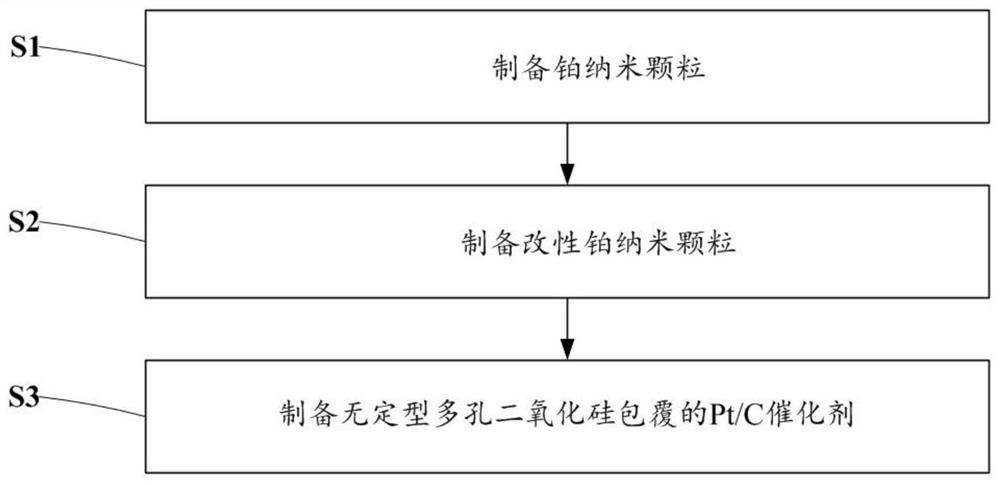

[0018] see figure 1 , the first aspect of the present invention provides a method for preparing a Pt / C catalyst coated with amorphous porous silica, comprising the following steps: preparing platinum nanoparticles S1; preparing modified platinum nanoparticles S2; preparing amorphous porous Silica-coated Pt / C catalyst S3. Each step is described in detail below.

[0019] The steps for preparing platinum nanoparticles S1 are as follows: adjust the pH of the platinum-containing solution to 10-12, add a reducing agent, heat to 80-100°C, stir and reflux for 2-4 hours, centrifuge and wash to obtain platinum nanoparticles. In this embodiment, the platinum-containing solution is an ethylene glycol solution of 0.005-0.05 mol / L chloroplatinic acid, the reducing agent is 1-5 mol / L sodium borohydride solution, and the platinum-containing solution is chloroplatinic acid and boron in the reducing agent The molar ratio of sodium hydride is (0.01-0.03):1. In this process, the solvent used f...

Embodiment 1

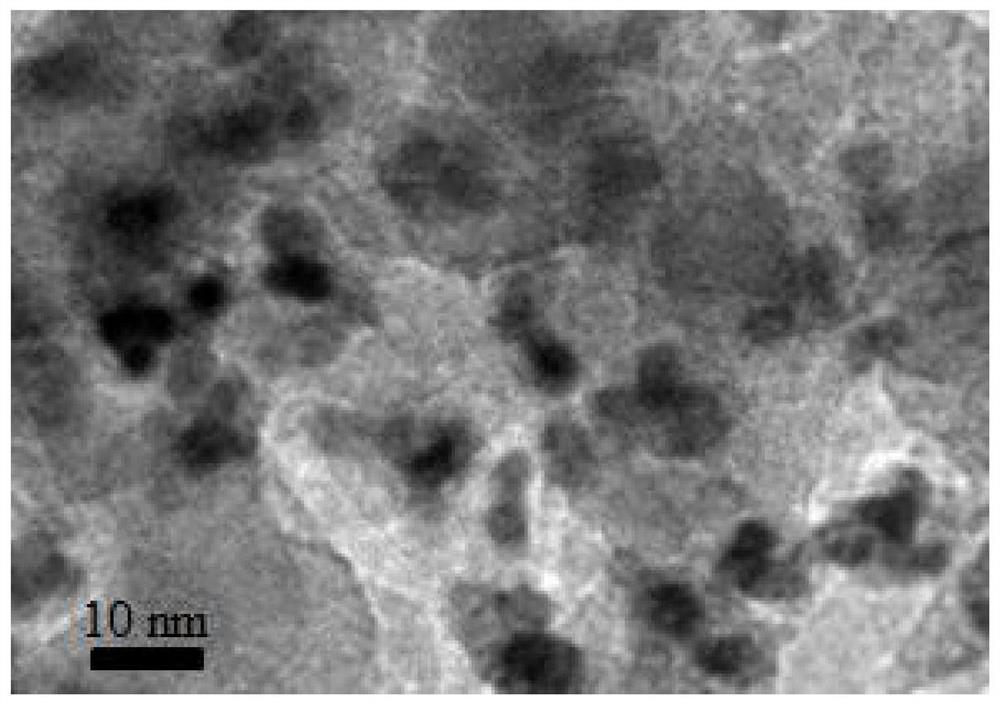

[0024] Adjust the pH of the platinum-containing solution prepared by 1.06g of chloroplatinic acid hexahydrate and 200mL of ethylene glycol to 11 with sodium hydroxide solution, keep stirring, and add 80ml of NaBH with a molar concentration of 1.5mol / L 4 The solution was heated to 90° C., stirred and refluxed for 3 h, centrifuged and washed with a mixed solution of ethanol and water at a volume ratio of 1:1 to obtain platinum nanoparticles.

[0025] Disperse the above-mentioned platinum nanoparticles in 100ml of deionized water, then add 0.4g of polyvinylpyrrolidone, stir for 20h, then add a mixed solution of 0.4g of cetyltrimethylammonium bromide and 200mL of isopropanol, and continue stirring for 1h. Centrifuge to obtain modified platinum nanoparticles.

[0026]Add the above-mentioned modified platinum nanoparticles into 300ml of carbon black dispersion with a mass concentration of 2g / L, stir at room temperature for 12h, adjust the pH to 10 with sodium hydroxide solution, and...

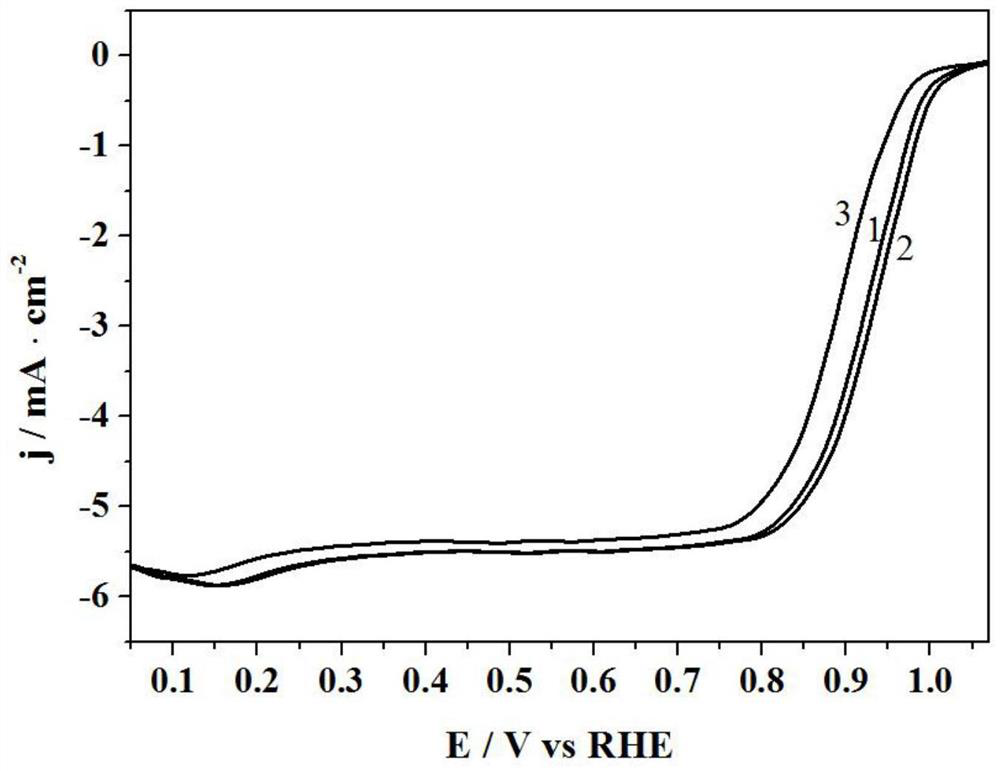

Embodiment 2

[0029] Adjust the pH of the platinum-containing solution prepared by 0.53g of chloroplatinic acid hexahydrate and 200mL of ethylene glycol to 11 with sodium hydroxide solution, keep stirring, and add 60ml of NaBH with a molar concentration of 1mol / L 4 The solution was heated to 90° C., stirred and refluxed for 3 h, centrifuged and washed with a mixed solution of ethanol and water at a volume ratio of 1:1 to obtain platinum nanoparticles.

[0030] Disperse the above platinum nanoparticles in 20ml of deionized water, then add 0.04g of polyvinylpyrrolidone, stir for 18h, then add a mixed solution of 0.04g of cetyltrimethylammonium bromide and 50mL of isopropanol, and continue stirring for 1.5h , centrifuged to obtain modified platinum nanoparticles.

[0031] Add the above-mentioned modified platinum nanoparticles to 400ml of carbon black dispersion with a mass concentration of 2g / L, stir at room temperature for 12h, adjust the pH to 10 with sodium hydroxide solution, and add 0.5m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com