High-cohesiveness solid electrolyte prepared by in-situ curing, preparation method and application thereof

A technology of solid electrolyte and high adhesion, which is applied in the direction of solid electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte, etc., and can solve problems such as poor rate and cycle performance, and large solid/solid interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

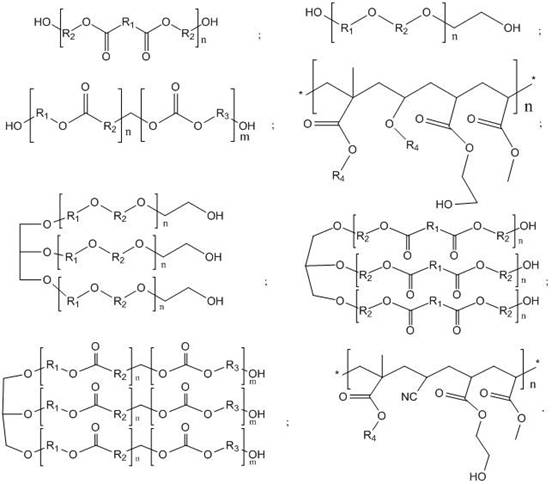

Method used

Image

Examples

preparation example Construction

[0056] (1) Preparation of positive electrode sheet

[0057] 1) Dissolve polyvinylidene fluoride (PVDF) in N,N-2-methylpyrrolidone with a solid content of 6%.

[0058] 2) After mixing the positive electrode active material, PVDF solution, and conductive carbon black at a mass ratio of 95:2:3, grind for at least 3 hours, wherein the positive electrode active material is lithium cobaltate, lithium iron phosphate, lithium manganese iron phosphate, manganese One of Lithium Oxide, Lithium Nickel Manganese Oxide and NCM ternary materials.

[0059] 3) Apply the slurry obtained in the previous step evenly on the aluminum foil with a thickness of 50-100 μm, and dry it at 80°C first, and the positive active material content is less than 10 mg / cm 2 , rolled, and then dried in a vacuum oven at 120°C, punched, weighed and then dried in a vacuum oven at 120°C, and placed in a glove box for use.

[0060] 4) Cut to size.

[0061] (2) Preparation of negative electrode sheet

[0062] 1) Afte...

Embodiment 1

[0072] In a glove box filled with argon, LiTFSI and LiPF 6 Dissolve in hydroxyl-terminated oligomer A1 and succinonitrile, stir for 2 hours to dissolve completely, then add terminal isocyanate group-containing compound B1 and porous PMMA particles, stir well, and finally add dibutyltin dilaurate, each The ratio of components is shown in Table 1.

[0073] Quickly inject the mixed electrolyte raw materials into the cell, let it stand for 24 hours, extract excess electrolyte, and then heat at 50°C for 2 hours.

[0074] The long-term cycle performance of the full battery of NCM811 on silicon carbon was tested. When the capacity retention rate decayed to 80%, a total of 850 cycles were cycled.

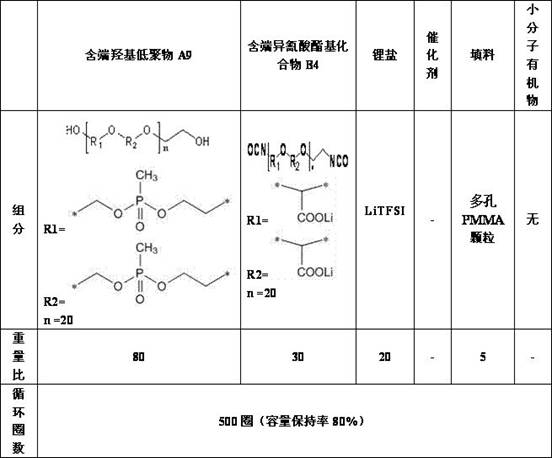

[0075] Table 1

[0076]

Embodiment 2

[0078] In a glove box filled with argon, the LiDFOB / LiPF 6 Dissolve in hydroxyl-terminated oligomer A2 and succinonitrile, stir for 2 hours to dissolve completely, then add terminal isocyanate group-containing compound B2 and porous PMMA particles, stir well, and finally add dibutyltin dilaurate, each The ratio of components is shown in Table 2.

[0079] Quickly inject the mixed electrolyte into the cell, let it stand for 24 hours, extract the excess electrolyte, and then heat it at 50°C for 2 hours.

[0080] The long-term cycle performance of the full battery of NCM811 on silicon carbon was tested. When the capacity retention rate decayed to 80%, a total of 850 cycles were cycled.

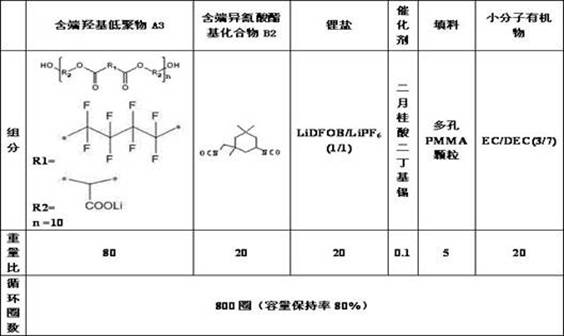

[0081] Table 2

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com