Multilayer extrusion type transparent solar photovoltaic backboard

A solar photovoltaic and multi-layer extrusion technology, applied in the field of solar photovoltaic, can solve the problems of acetic acid not easy to discharge, PID phenomenon, easy to produce pollution, etc., achieve high peel strength, avoid recycling pollution, and high water vapor barrier performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

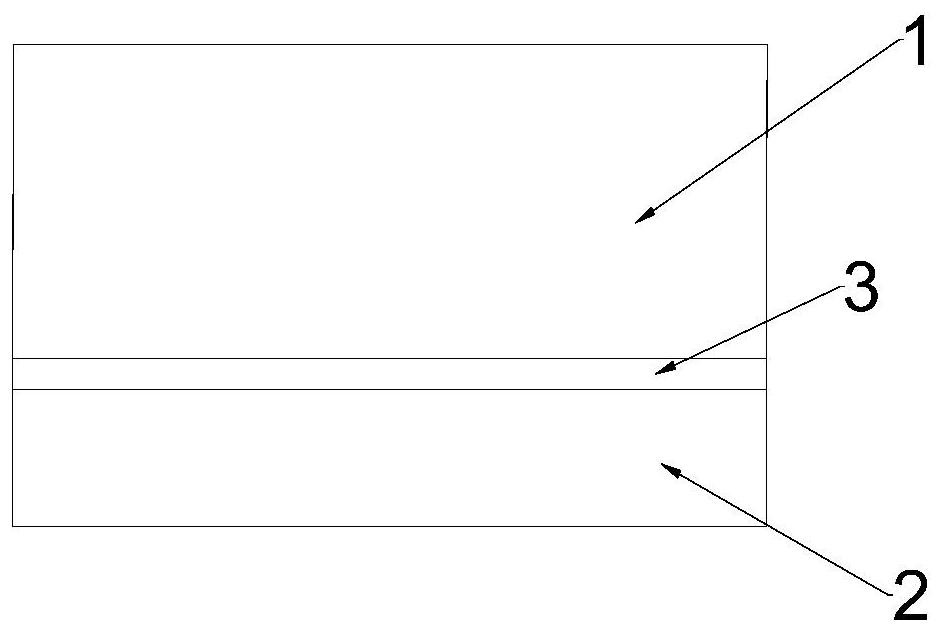

[0022] Embodiment one, such as figure 1 As shown, a multi-layer extruded transparent solar photovoltaic backsheet includes a transparent outer layer 1 and a transparent inner layer 2 that are bonded to each other, and the transparent outer layer 1 is polypropylene (PP) and polyolefin elastomer ( POE) mixed to form a transparent modified polyolefin material, wherein the weight ratio of polypropylene to polyolefin elastomer is 100:20, and the transparent outer layer 1 also contains a certain amount of ultraviolet absorbers and antioxidants. The transparent inner layer 2 is made of a transparent modified polyolefin material, and the transparent modified polyolefin material of this layer is formed by mixing polyethylene (PE) and polyolefin elastomer (POE), wherein polyethylene and polyolefin elastomer The weight ratio is 100:20, and the transparent inner layer 2 also contains a certain amount of ultraviolet absorber and antioxidant. The above-mentioned ultraviolet absorbers are b...

Embodiment 2

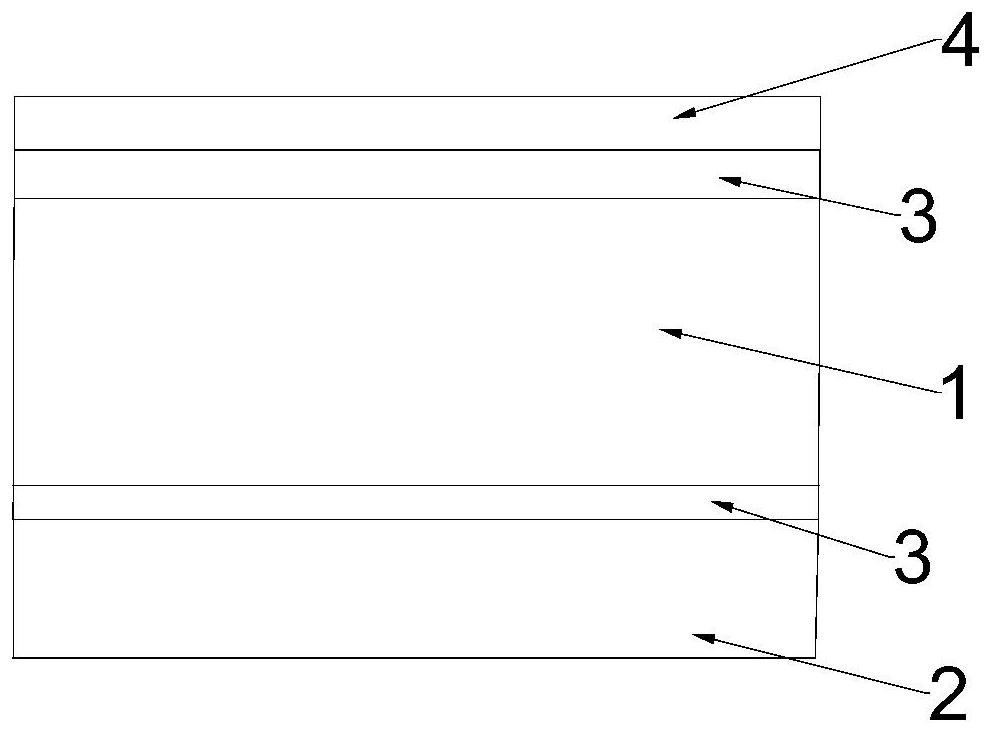

[0024] Embodiment two, such as figure 2 As shown, a multi-layer extruded transparent solar photovoltaic backsheet includes a barrier protective layer 4, a transparent outer layer 1 and a transparent inner layer 2 arranged in sequence, and the components of the transparent outer layer 1 and the transparent inner layer 2 and The thickness is the same as in Example 1. The barrier protection layer 4 is made of ethylene-vinyl alcohol copolymer (EVOH), and when the barrier protection layer 4 is made of the ethylene-vinyl alcohol copolymer, a certain amount of additives such as plasticizer, heat stabilizer, and antioxidant are added. Control the alkaline earth metal salt in the ethylene-vinyl alcohol copolymer below 5ppm. The ethylene content in the ethylene-vinyl alcohol copolymer is controlled between 25-50 mole percent. Apply viscose between the transparent outer layer 1 and the transparent inner layer 2, between the barrier protective layer 4 and the transparent outer layer 1,...

Embodiment 3

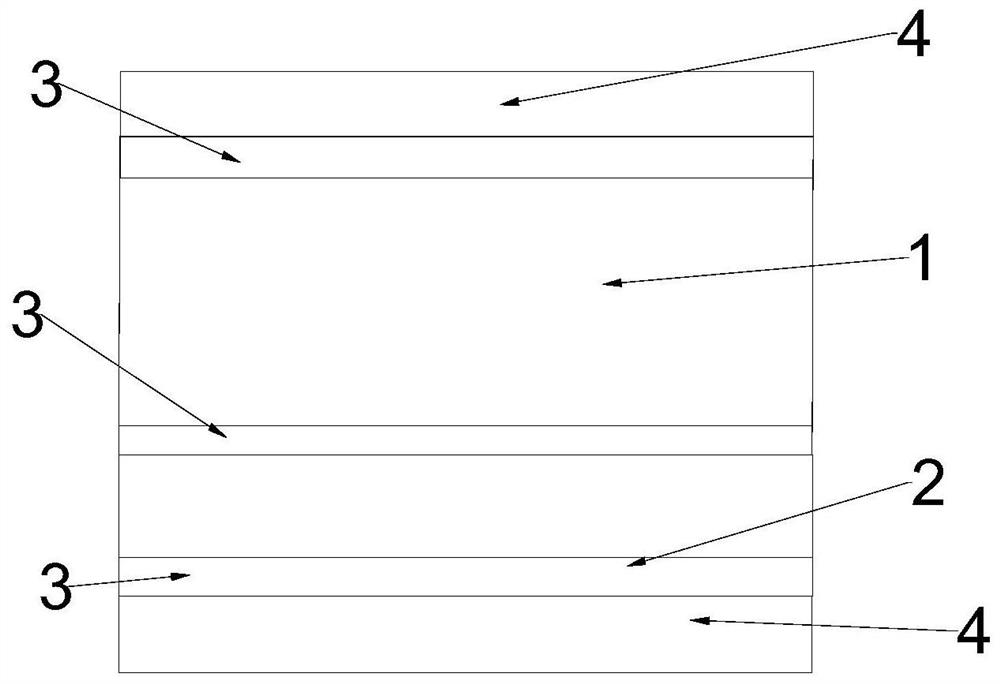

[0025] Embodiment three, such as image 3 As shown, a multi-layer extruded transparent solar photovoltaic backsheet includes a barrier protection layer 4, a transparent outer layer 1, a transparent inner layer 2 and a barrier protection layer 4 arranged in sequence, the transparent outer layer 1 and the transparent inner layer The composition and thickness of layer 2 are the same as those in Example 1. Both barrier protection layers 4 are made of polyvinylidene chloride (PVDC), and their thicknesses are the same as those of the barrier protection layer 4 in the second embodiment. The backsheet is formed by co-extrusion with an extruder, and an adhesive layer 3 with the same function is also formed between the transparent inner layer 1 and the barrier protection layer 4 . The backboard of this embodiment structure is a co-extruded transparent backboard 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com