Method and device for preparing ethyl methyl carbonate by utilizing dividing wall reactive distillation tower

A reactive distillation column, a technology of ethyl methyl carbonate, applied in the chemical method of reacting liquid with liquid, purification/separation of carbonate/haloformate, separation method, etc., can solve the complex process and energy consumption. And the problem of high equipment cost, to achieve the effect of low energy consumption and equipment cost, improve market competitiveness and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

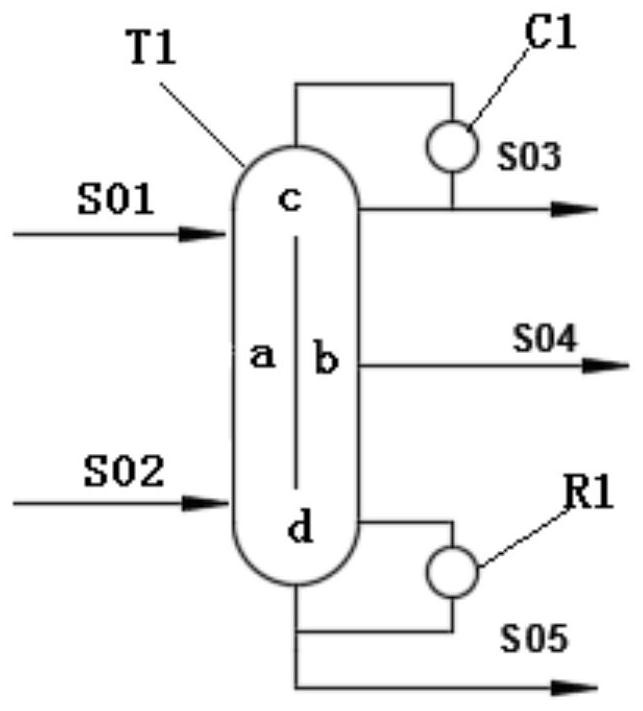

[0020] Device of the present invention is used for ethyl methyl carbonate preparation process, as figure 1 As shown, it includes a dividing wall reactive distillation column, a condenser, a reboiler, and related feed lines and lines connecting the above equipment.

[0021] The dimethyl carbonate reactant added is 1kg, and the ethanol reactant with equimolar number is added, the sulfuric acid catalyst added is 2kg, the theoretical plate number of the pre-separation column section is 10, and the theoretical plate number of the main column section is 100 , the ethyl methyl carbonate product is extracted from the 50th theoretical plate of the main column section, the theoretical plate number of the public rectification section is 0, the theoretical plate number of the public stripping section is 50, and the liquid phase reflux enters the pre-separation column section The mass fraction is 0.01, the mass fraction of gas phase reflux into the pre-separation tower section is 0.01, the...

Embodiment 2

[0023] Device of the present invention is used for ethyl methyl carbonate preparation process, as figure 1 As shown, it includes a dividing wall reactive distillation column, a condenser, a reboiler, and related feed lines and lines connecting the above equipment.

[0024] The dimethyl carbonate reactant that adds is 1kg, and the ethanol reactant that adds 10 times of moles, the sulfuric acid catalyst that adds is 1kg, and the pre-separation column section theoretical plate number is 200, and the main column section theoretical plate number is 10, Extract the ethyl methyl carbonate product from the 10th theoretical plate of the main column section, the theoretical plate number of the public rectification section is 0, the theoretical plate number of the public stripping section is 50, and the mass of the liquid phase reflux entering the pre-separation column section The fraction is 0.99, the mass fraction of gas phase reflux entering the pre-separation tower section is 0.99, t...

Embodiment 3

[0026] Device of the present invention is used for ethyl methyl carbonate preparation process, as figure 1 As shown, it includes a dividing wall reactive distillation column, a condenser, a reboiler, and related feed lines and lines connecting the above equipment.

[0027] The dimethyl carbonate reactant that adds is 1kg, and the ethanol reactant that adds 10 times of moles, the sulfuric acid catalyst that adds is 1kg, and the pre-separation column section theoretical plate number is 100, and the main column section theoretical plate number is 10, Extract the ethyl methyl carbonate product from the 10th theoretical plate of the main column section, the theoretical plate number of the public rectification section is 0, the theoretical plate number of the public stripping section is 50, and the mass of the liquid phase reflux entering the pre-separation column section The fraction is 0.99, the mass fraction of gas phase reflux entering the pre-separation tower section is 0.99, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com