Micro-gap test device for stamping formed stainless steel plate

A stainless steel plate and testing device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of troublesome operation process, reduce the work efficiency of technicians, etc., and achieve the effect of reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

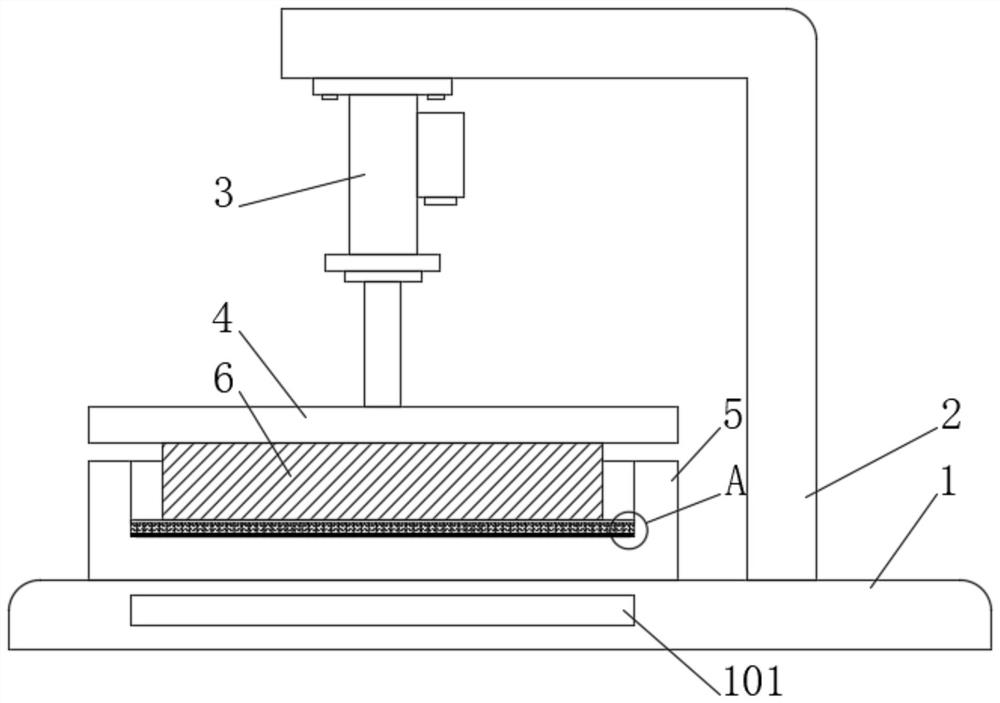

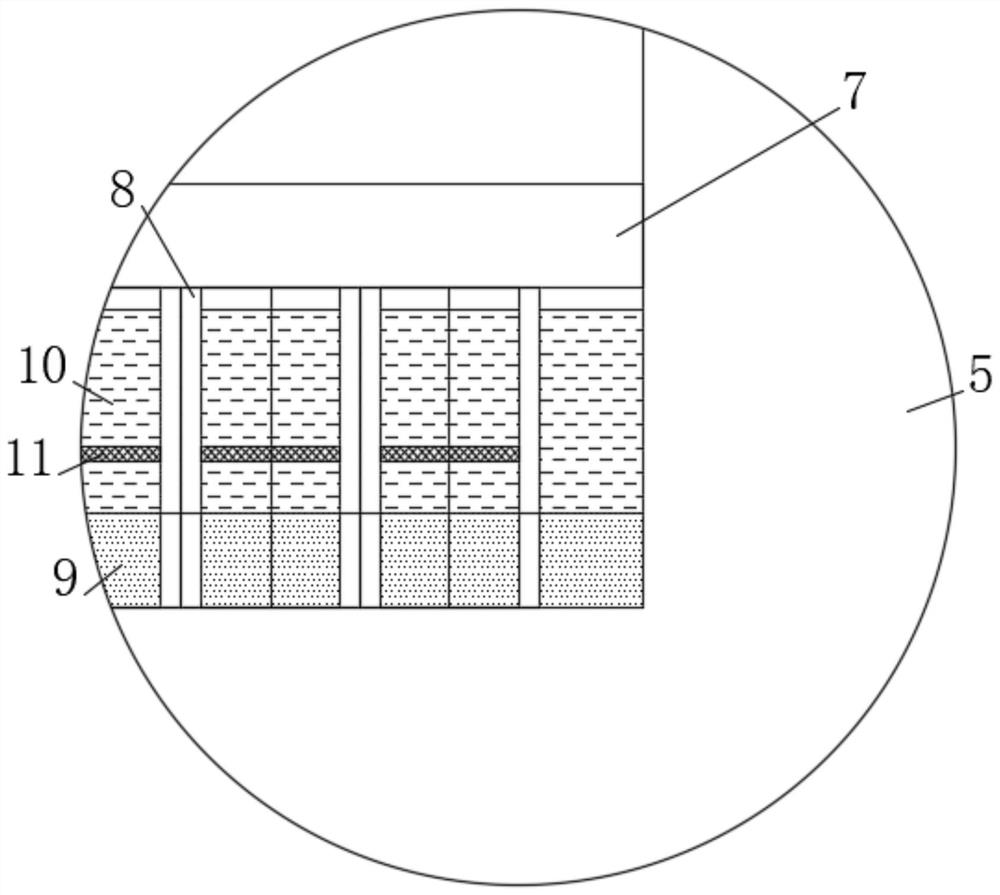

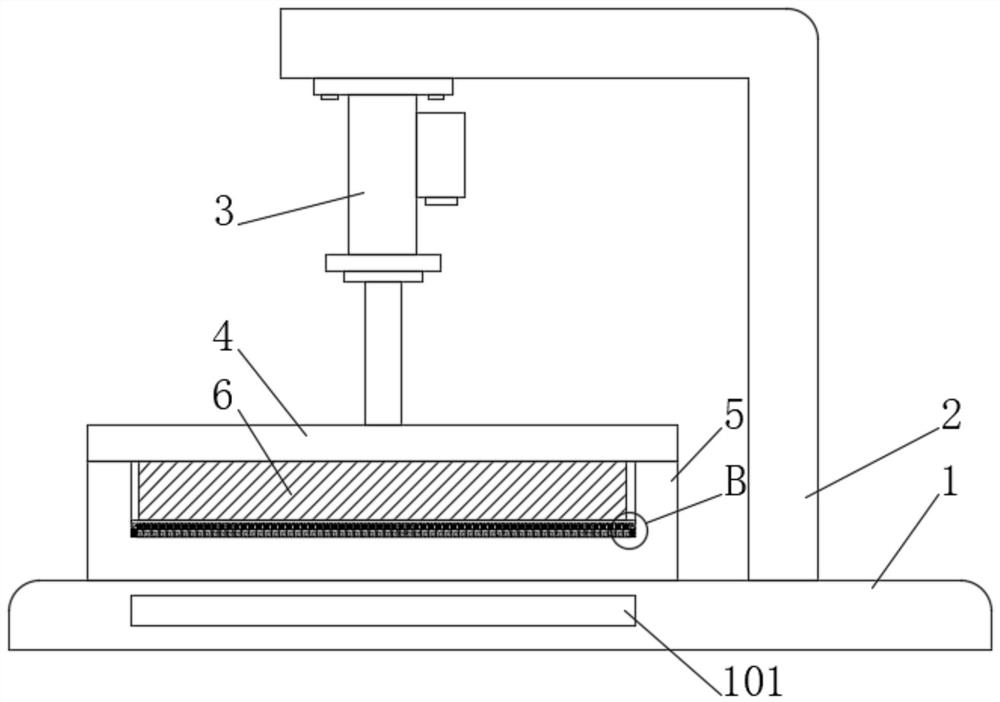

[0043] see Figure 1-5 , a stamping-formed stainless steel plate micro-gap test device, comprising a stamping test base 1, the upper end of the stamping test base 1 is fixedly connected with an L-shaped connecting plate 2 equipped with a cylinder 3, the cylinder 3 is located on the upper side of the stamping test base 1, and the cylinder 3 The power output end of the power output end is fixedly connected with a stamping plate 4, and the upper end of the stamping test base 1 is fixedly connected with a storage mold 5 located at the lower side of the stamping plate 4. The storage mold 5 is provided with a stainless steel plate 6, and the inner wall of the storage mold 5 is fixedly connected with a stainless steel plate. 6 The contact plate 7 on the lower side and in contact with the stainless steel plate 6 is fixedly connected between the contact plate 7 and the inner bottom end of the storage mold 5, and a plurality of evenly distributed and fixedly connected beam-splitting supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com