Preparation method and application of titanium alloy surface iodine-loaded antibacterial coating

An antibacterial coating and titanium alloy technology, applied in the field of pharmaceutical biomaterial preparation, can solve the problems of inability to achieve antibacterial effect, no longer suitable, poor antibacterial performance, etc., achieve high-efficiency and long-lasting antibacterial effect, prevent explosive release, prolong The effect of release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

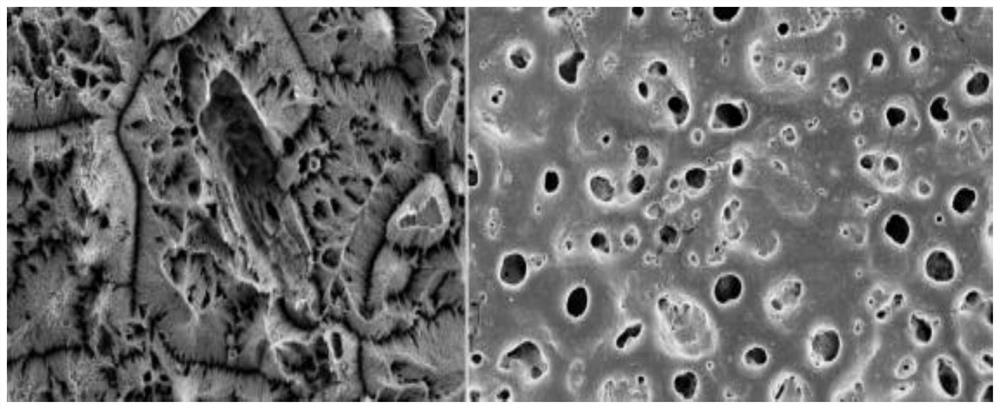

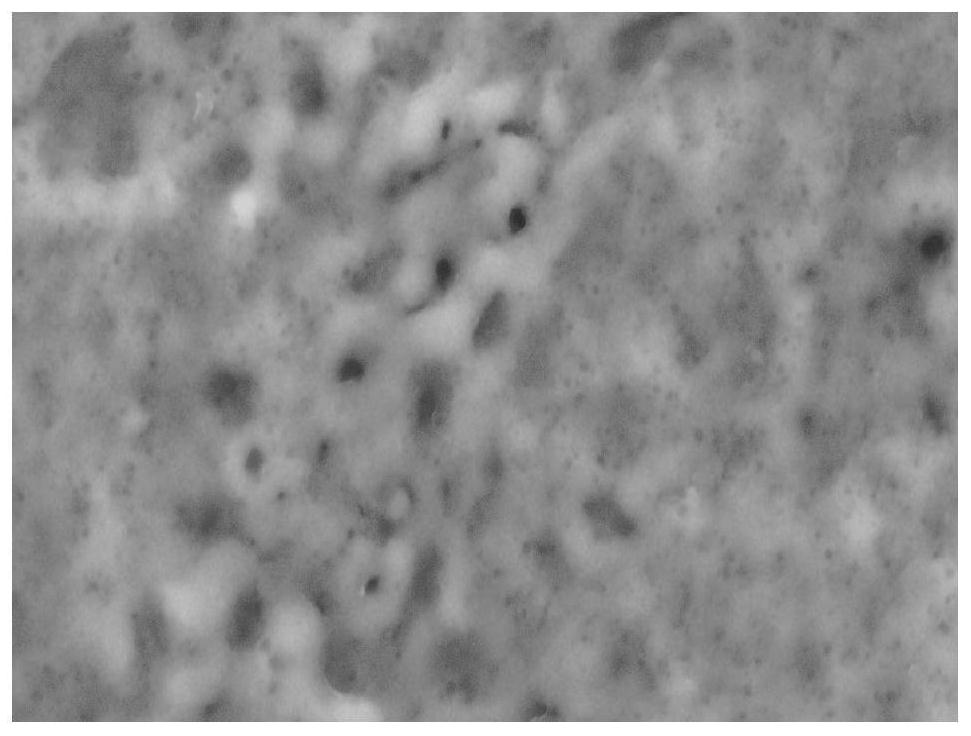

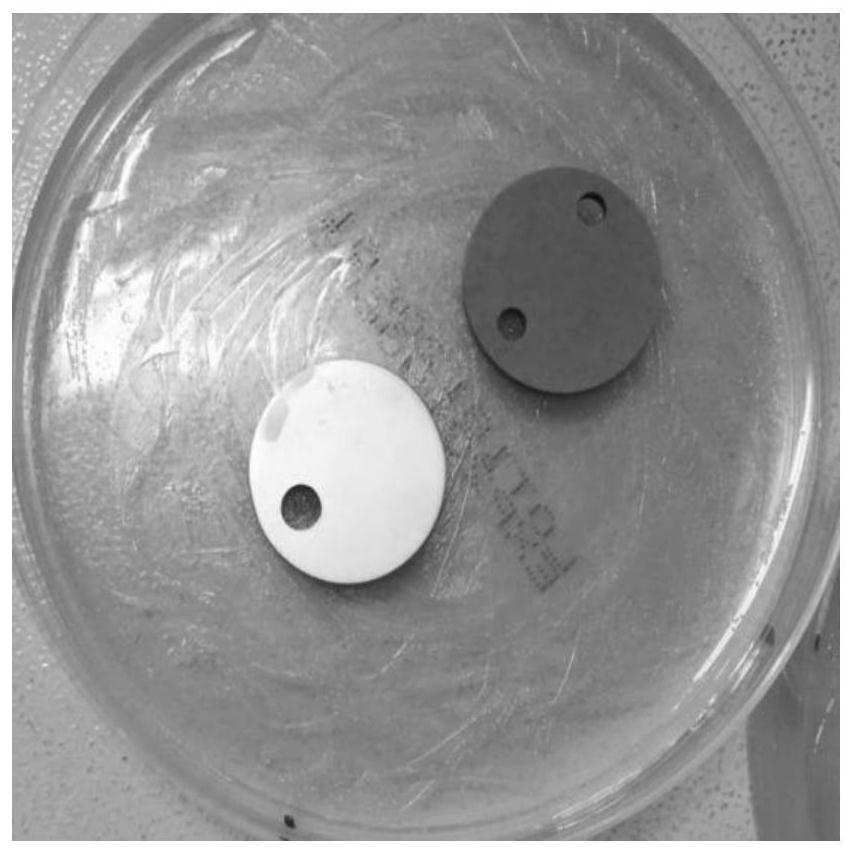

[0054] A method for preparing an iodine-carrying antibacterial coating on the surface of a titanium alloy, comprising the following steps:

[0055] (1) Degreasing the titanium alloy to obtain the substrate A;

[0056] (2) Substrate A is sandblasted and polished to a uniform surface to obtain substrate B;

[0057] (3) Substrate B is cleaned with ultrasonic waves to obtain substrate C;

[0058] (4) Pickling the substrate C: firstly, at room temperature, treat it with the pickling solution 1 for 10 seconds; then, at 40° C., treat it with the pickling solution 2 for 3 minutes; obtain the substrate D;

[0059] (5) Washing, rinsing and spraying the substrate D with purified water in sequence to obtain the substrate E;

[0060] (6) Put the substrate E in the micro-arc anodizing working solution, and perform micro-arc anodizing treatment for 10 minutes, with a voltage of 160V, a temperature of 10°C, and a frequency of 300H Z , the duty ratio is 10%, and the substrate F is obtained;...

Embodiment 2

[0081] A method for preparing an iodine-carrying antibacterial coating on the surface of a titanium alloy, comprising the following steps:

[0082] (1) Degreasing the titanium alloy to obtain the substrate A;

[0083] (2) Substrate A is sandblasted and polished to a uniform surface to obtain substrate B;

[0084] (3) Substrate B is cleaned with ultrasonic waves to obtain substrate C;

[0085] (4) Pickling the substrate C: firstly, at room temperature, treat it with pickling solution 1 for 15 seconds; then, treat it with pickling solution 2 at 50° C. for 5 minutes; obtain substrate D;

[0086] (5) Washing, rinsing and spraying the substrate D with purified water in sequence to obtain the substrate E;

[0087] (6) Put the base material E in the micro-arc anodizing working solution, and carry out the micro-arc anodizing treatment for 11 minutes, the voltage is 180V, the temperature is 15°C, and the frequency is 500H Z , the duty ratio is 10%, and the substrate F is obtained; ...

Embodiment 3

[0108] A method for preparing an iodine-carrying antibacterial coating on the surface of a titanium alloy, comprising the following steps:

[0109] (1) Degreasing the titanium alloy to obtain the substrate A;

[0110] (2) Substrate A is sandblasted and polished to a uniform surface to obtain substrate B;

[0111] (3) Substrate B is cleaned with ultrasonic waves to obtain substrate C;

[0112] (4) Pickling the substrate C: firstly, at room temperature, treat it with pickling solution 1 for 20 seconds; then, treat it with pickling solution 2 at 60° C. for 5 minutes; obtain substrate D;

[0113] (5) Washing, rinsing and spraying the substrate D with purified water in sequence to obtain the substrate E;

[0114] (6) Put the substrate E in the working solution of micro-arc anodizing, and perform micro-arc anodizing treatment for 12 minutes, with a voltage of 200V, a temperature of 20°C, and a frequency of 1000H Z , the duty ratio is 10%, and the substrate F is obtained;

[0115] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com