Berberine sulfate or hydrochloride multi-vesicular liposome and preparation method thereof

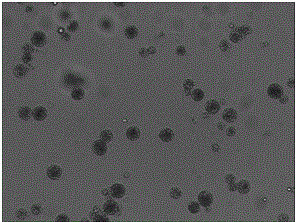

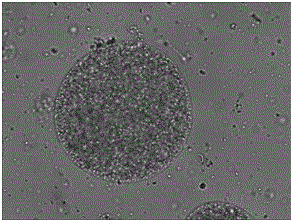

A technology of multivesicular liposomes and berberine hydrochloride, which is applied in the field of liposomes, hydrochloric acid or sulfated liposomes, can solve the problem of high solubility of berberine sulfate or berberine hydrochloride, the inability to obtain stable final products, and the difficulty of multivesicular systems. Damaged and other problems, to achieve the effect of good appearance, uniform size and large number of vesicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

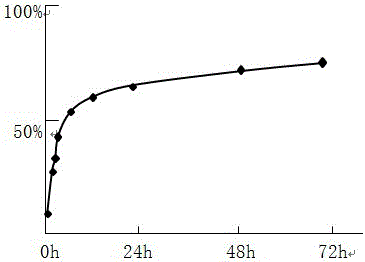

Examples

Embodiment 1

[0049] (1) Dissolve 0.2g of lecithin, 0.1g of cholesterol, 0.1mL of oleic acid, and 0.5mL of triolein in 7.5mL of a mixed solvent formed of ether and chloroform at a volume ratio of 1:1 In, the oil phase is obtained;

[0050] (2) Dissolve 0.0375 g of berberine sulfate in 7.5 mL of sucrose solution with a concentration of 5 wt % to form an inner water phase;

[0051] (3) Take the internal water phase with a volume ratio of 1:1 to the oil phase and slowly inject it into the oil phase, and pass it through a high-speed homogenizer at 12000r.min -1 Homogenize for 9 minutes at a high speed to obtain colostrum;

[0052] (4) Take 4mL of colostrum and quickly pour it into the mixed solution to form the outer water phase, and pass it through a high-speed homogenizer at 9500 r.min -1 Homogenize at a rate of 1min to obtain double emulsion, and the concentration of L-lysine in the mixed solution is 40mmol.L -1 , the concentration of sodium alginate is 0.5wt%, and the concentration of gl...

Embodiment 2

[0057] (1) Dissolve 0.2g of lecithin, 0.2g of cholesterol, 0.5mL of oleic acid, and 0.3mL of triolein in 7.5mL of a mixed solvent formed of ether and chloroform at a volume ratio of 0.5:1 to obtain oil Mutually;

[0058] (2) Dissolve 0.1 g of berberine sulfate in 3.75 mL of sucrose solution with a concentration of 7 wt % to form an inner water phase;

[0059] (3) Take the internal water phase with a volume ratio of 0.5:1 to the oil phase and slowly inject it into the oil phase, and pass it through a high-speed homogenizer at 10000r.min -1 Homogenize for 15 minutes at a speed of 1 to obtain colostrum;

[0060] (4) Take 5mL of colostrum and quickly pour it into the mixed solution to form the outer water phase, and pass it through a high-speed homogenizer at 9000r.min -1 homogeneous at a rate of 3min to obtain double emulsion, and the concentration of L-lysine in the mixed solution is 30mmol.L -1 , the concentration of sodium alginate is 0.3wt%, the concentration of glucose is...

Embodiment 3

[0064] (1) Dissolve 0.2g of lecithin, 0.04g of cholesterol, 0.3mL of oleic acid, and 0.4mL of triolein in 7.5mL of a mixed solvent formed of ether and chloroform at a volume ratio of 1.5:1 to obtain an oil phase ;

[0065] (2) Dissolve 0.05 g of berberine sulfate in 11.25 mL of sucrose solution with a concentration of 6 wt % to form an inner water phase;

[0066] (3) Take the internal water phase with a volume ratio of 1.5:1 to the oil phase and slowly inject it into the oil phase, and pass it through a high-speed homogenizer at 11000r.min -1 Homogenize at a speed of 10 min to obtain colostrum;

[0067] (4) Take 6mL of colostrum and quickly pour it into the mixed solution to form the outer water phase, and pass it through a high-speed homogenizer at 10000r.min -1 Homogenize at a rate of 1min to obtain double emulsion, and the concentration of L-lysine in the mixed solution is 50mmol.L -1 , the concentration of sodium alginate is 0.4wt%, the concentration of glucose is 6wt%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com