A Nanoparticle-Driven Method for Low-Energy Ultrasonic Metal Welding

A nanoparticle and metal welding technology, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of unfavorable application due to surface damage, reduce welding input energy, and limit application prospects, so as to achieve easy control of welding quality, Reduced risk, flexible and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of nano copper paste, it adopts the following steps to prepare:

[0038] 1. Take by weighing 10 g of copper sulfate pentahydrate powder and join in 40 ml of ethylene glycol, and be heated to 75° C., obtain solution A after the copper sulfate pentahydrate powder is completely dissolved.

[0039] II. Weigh 16 g of sodium hypophosphite powder and 10 g of polyvinylpyrrolidone into 160 ml of ethylene glycol, and heat to 75° C. After the powder is completely dissolved, solution B is obtained.

[0040] III. Slowly adding solution A into solution B, heating to 75° C. and reacting for 1.5 h to prepare dispersion liquid C containing copper nanoparticles.

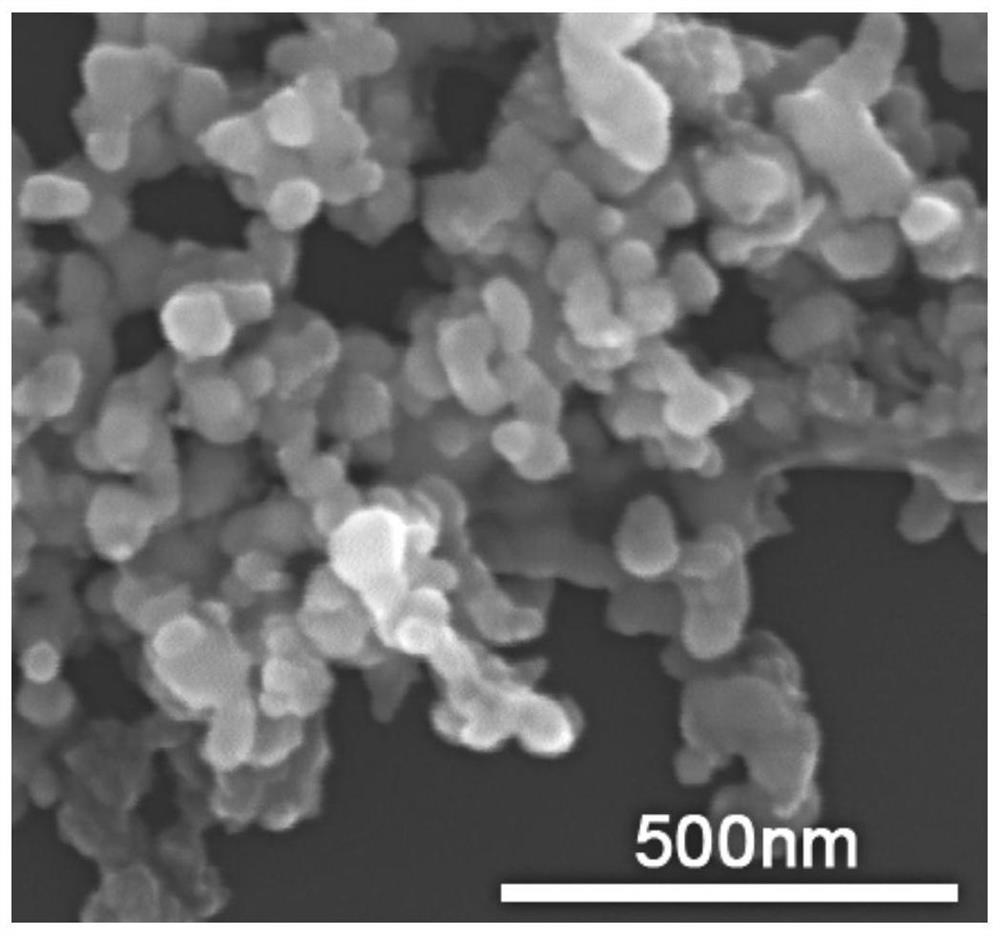

[0041] IV. After the dispersion liquid C is cooled to room temperature, centrifugation is performed to separate the copper nanoparticles and the organic solvent. The separated copper nanoparticles were washed 2-4 times with a mixed solution D of deionized water and absolute ethanol in ultrasonic vibration. The size of ...

Embodiment 2

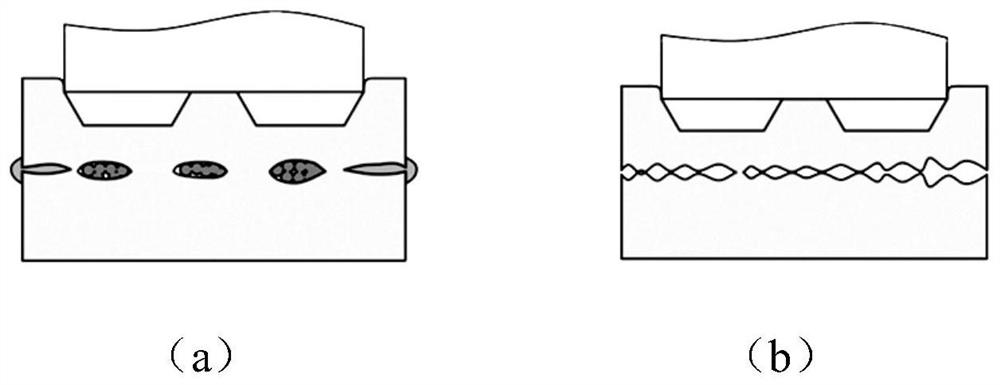

[0045] Ultrasonic welding of copper-copper metal and interface characterization using nano-copper paste intermediate layer

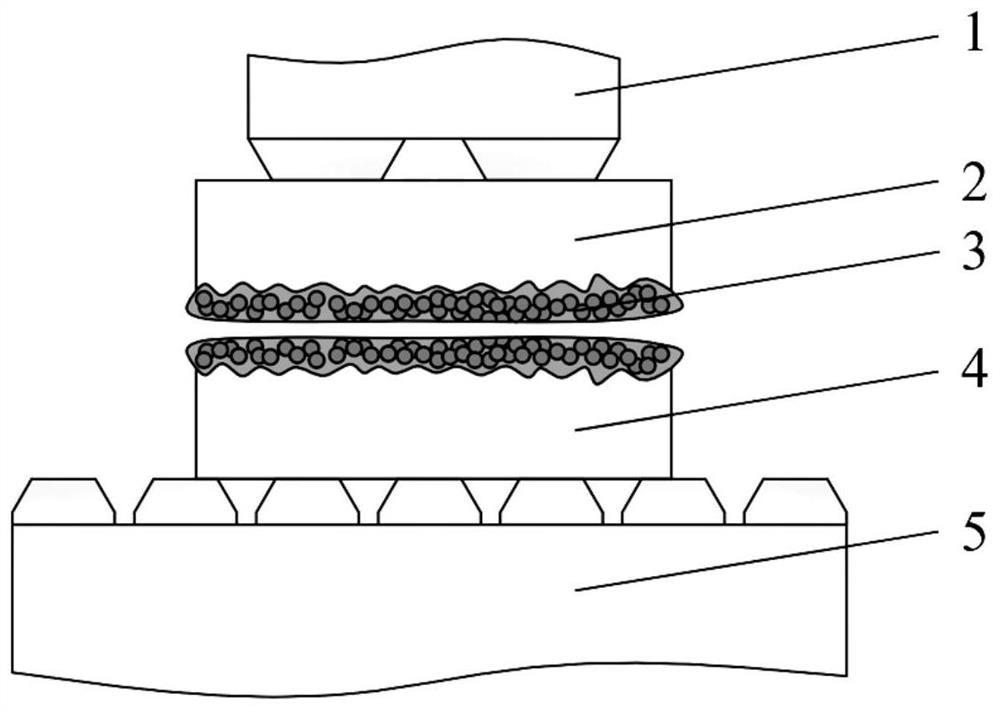

[0046] like figure 2As shown, using the nano-copper paste of Example 1 to ultrasonically weld copper-copper metal, including the following steps:

[0047] 1. The upper layer of material to be welded 2 and the lower layer of material to be welded 4 are both 20 mm × 10 mm × 0.5 mm copper strips, and the connection surface of the material to be welded 2 and the material to be welded 4 is polished with 800# sandpaper to remove the surface oxide layer, and then Immerse in absolute ethanol for ultrasonic cleaning for 3 min.

[0048] II. Select the interlayer nano-particle paste as nano-copper paste, screen-print the copper nano-particle paste with a thickness of 10 μm on the surfaces of the material to be welded 2 and the material to be welded 4, and use figure 2 Place the upper and lower layers of copper strips to be soldered in the manner shown.

[0049...

Embodiment 3

[0056] Example 3 Ultrasonic welding of aluminum-copper metal using nano-copper paste intermediate layer

[0057] A method for ultrasonically welding aluminum-copper metal using copper nanoparticles, comprising the following steps:

[0058] I. The material to be welded on the upper layer is aluminum strip, and the material to be welded on the lower layer is copper strip, both of which are 20 mm×10 mm×0.5 mm in size. The connection surface of the material to be welded and the material to be welded is polished with 800# sandpaper to remove the surface oxide layer , and then immersed in absolute ethanol for ultrasonic cleaning for 3 min.

[0059] II. Select the interlayer nano-particle paste as nano-copper paste, screen-print nano-copper paste with a thickness of 10 μm on the surface of the material to be welded and the material to be welded, and use such as figure 2 Place the upper and lower layers of copper strips to be soldered in the manner shown.

[0060] III. According to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com