Welding and packaging integrated method for high-temperature superconducting tape

A high-temperature superconducting tape, welding and packaging technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven surface, low joint strength, thickness difference, etc., to meet the preparation requirements, uniform thickness, The effect of smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

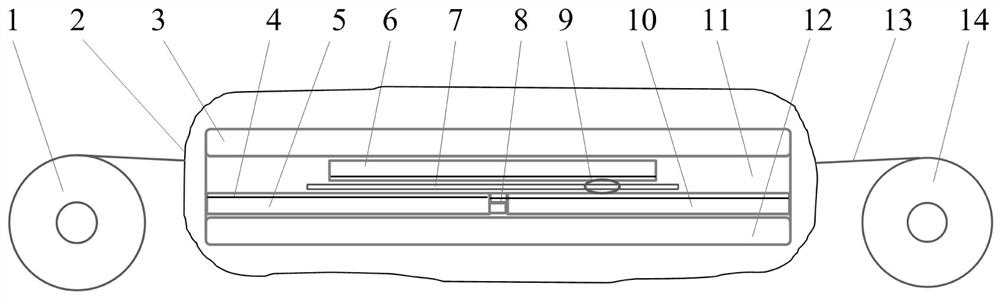

[0026] Embodiment 1, with reference to figure 1 , an integrated method for welding and packaging high-temperature superconducting tapes, the superconducting tape 13 produced by the method includes a tape A1 part, a bridge structure joint 2 and a tape B14 part. Its production includes the following steps: Step 1, corroding the superconducting surface side of one end of the superconducting core tape A5 (covered with the superconducting layer 4), the length is 1-3 cm, and the corrosion thickness is 1 / 2 of the thickness of the superconducting core tape, such as figure 2 and image 3 The corroded surface 15 on the side of the superconducting surface at the end of the superconducting core ribbon A is shown. After the corrosion is completed, cut the corroded surface 15 on the superconducting surface side at the end of the superconducting core strip A so that its length is less than 2mm; after corrosion, the Hastelloy surface is exposed. In addition, the corroded surface 15 on the ...

Embodiment 2

[0037] Example 2, the high-temperature melting point solder sheet 7 is made of Sn-Ag-Cu alloy sheet, the upper packaging layer 3 and the lower packaging layer 12 are made of pure copper, and the superconducting core tape A5, superconducting core tape B10 and superconducting core tape C6 are made of Copper-coated superconducting tape, the rest are the same as in Embodiment 1.

Embodiment 3

[0038] Embodiment 3, the high-temperature melting point solder sheet 7 is made of Sn-Ag-Cu alloy sheet, the material of the upper packaging layer 3 and the lower packaging layer 12 is made of brass, and the superconducting core tape A5, the superconducting core tape B10 and the superconducting core tape C6 are made of Copper-coated superconducting tape, the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com