Fireproof UV pre-coated paper and manufacturing method thereof

A manufacturing method and technology of pre-coated paper, applied in special paper, fire retardant addition, coating and other directions, can solve the problem of affecting the fire performance and aesthetics of wooden fire doors, reducing the fire performance of wooden fire doors, and easy cracking of wooden fire doors, etc. problem, to achieve good fire resistance, improve fire performance, and improve the effect of edge sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

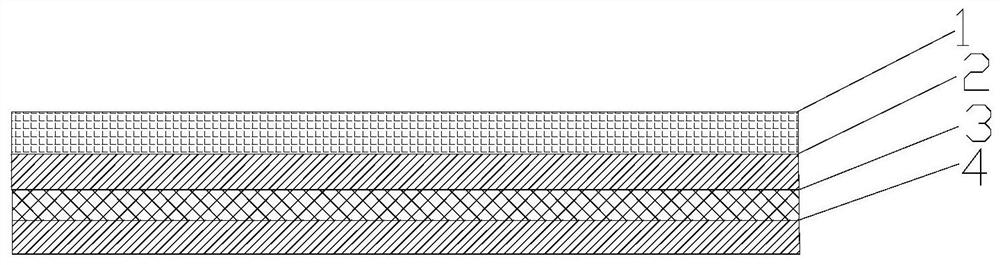

[0048] Such as figure 1 Shown, a kind of fireproof UV pre-coated paper comprises first fireproof layer 4, paper layer 3, second fireproof layer 2, fireproof UV paint layer 1 from bottom to top successively, the raw material of described first fireproof layer 4 and the second The raw materials of the fireproof layer 2 are the same. The thickness of the paper layer is 25 silk, and the air permeability is 200μm / Pa·s.

[0049] The raw materials of the first fireproof layer 4 and the second fireproof layer 2 are, in parts by weight, 10 parts of fireproof liquid and 90 parts of water-based paint.

[0050] The raw materials of the fireproof liquid are, in parts by weight, 1 part of fireproof flame retardant and 2 parts of deionized water. The fireproof flame retardant is purchased from Sanyu Chemical (Shenzhen) Co., Ltd., and the model is FHZRJ.

[0051] The water-based paint is a water-based acrylic emulsion with a solid content of 38%, purchased from BASF (China) Co., Ltd., and t...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that the thickness of the paper layer is 50 filaments, and the air permeability is 230 μm / Pa·s. The raw materials of the first fireproof layer and the second fireproof layer are, in parts by weight, 20 parts of fireproof liquid and 100 parts of water-based paint. The raw materials of the fireproof liquid are calculated as 1 part of fireproof flame retardant and 2 parts of deionized water in parts by weight. The solid content of the aqueous acrylic emulsion is 46%, and it is purchased from BASF (China) Co., Ltd., and the brand name is Joncryl 8055ap. The weight of the used fireproof UV paint per square meter of paper layer is 350g, purchased from Sweden Bona company, and the trade mark is 808W-DZ.

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 is that the thickness of the paper layer is 25 filaments, and the air permeability is 200 μm / Pa·s. The raw materials of the first fireproof layer and the second fireproof layer are, in parts by weight, 10 parts of fireproof liquid and 90 parts of water-based paint. The raw materials of the fireproof liquid are calculated as 1 part of fireproof flame retardant and 2 parts of deionized water in parts by weight. The water-based coating is a water-based polyurethane emulsion, the solid content of which is 35%, purchased from BASF, Germany, and the brand name is EB90A 52000. The weight of used fireproof UV paint per square meter paper layer is 200g, purchased from Sweden Bona company, the trade mark is 808W-DZ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com