Implementation method for promoting lignin depolymerization through pre-oxidation-catalytic hydrogenolysis

A technology for catalyzing hydrogenolysis and realizing methods, applied in lignin derivatives, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the waste of lignin resources and the biomass is less than 1% , the complex structure of lignin and other problems, to achieve the effect of significant gain, easy operation, and improve the overall yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

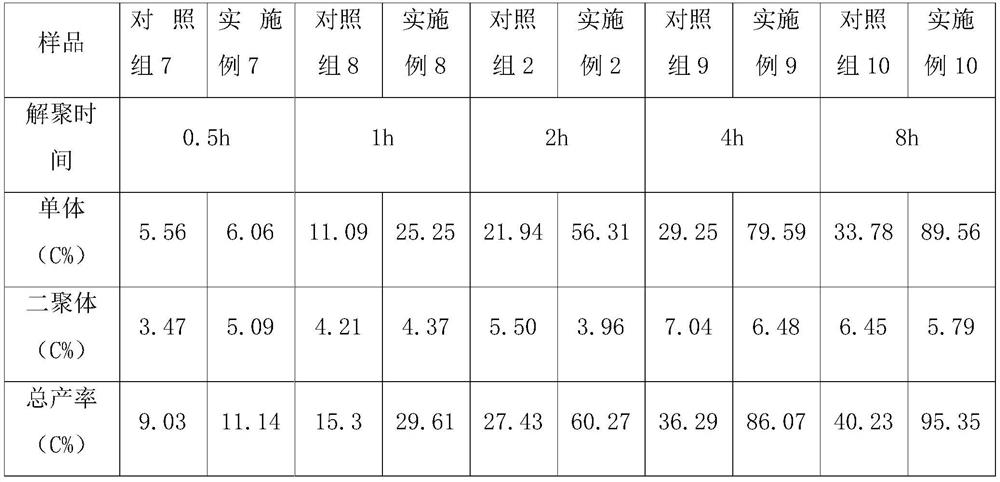

Embodiment 1

[0044] Add 1g of industrial lignin, 0.05g of 2,3-dichloro-5,6-dicyano-p-benzoquinone (DDQ), and 40ml of acetonitrile into the reactor, close the reactor, and use high-purity O 2 Purge 3-5 times, then fill the reactor with 1MPaO 2 , react at 90°C for 2 hours, after the reaction is over, place the reaction kettle in ice water to cool, then release the gas, and open the kettle; concentrate the pre-oxidized mixture under reduced pressure, and drop it into water or ether to precipitate when it becomes thick. Collect the precipitate and freeze-dry to obtain pre-oxidized lignin; 0.1g pre-oxidized lignin, 0.1gCuMgAlO x Catalyst and 2.4g ethanol are put into the reactor, react at 300 DEG C for 2h, the total yield of monomer and dimer after quantitative calculation of the liquid phase product obtained from the reaction is 36.56C% (unoxidized lignin decomposed under the same depolymerization condition The overall yield of polymerization was 27.43C%).

Embodiment 2

[0046] Add 1g of industrial lignin, 0.15g of 2,3-dichloro-5,6-dicyano-p-benzoquinone (DDQ), and 40ml of acetonitrile into the reactor, seal the reactor, and use high-purity O 2 Purge 3-5 times, then fill the reactor with 1MPaO 2 , react at 90°C for 2 hours, after the reaction is over, place the reaction kettle in ice water to cool, then release the gas, and open the kettle; concentrate the pre-oxidized mixture under reduced pressure, and drop it into water or ether to precipitate when it becomes thick. Collect the precipitate and freeze-dry to obtain pre-oxidized lignin; 0.1g pre-oxidized lignin, 0.1gCuMgAlO x The catalyst and 2.4g of ethanol were put into the reactor, and reacted at 300°C for 2h. The total yield of monomer and dimer after quantitative calculation of the liquid phase product obtained from the reaction was 60.27C%. The overall yield of polymerization was 27.43C%).

Embodiment 3

[0048] Add 1g of industrial lignin, 0.3g of 2,3-dichloro-5,6-dicyano-p-benzoquinone (DDQ), and 40ml of acetonitrile into the reactor, close the reactor, and use high-purity O 2 Purge 3-5 times, then fill the reactor with 1MPaO 2 , react at 90°C for 2 hours, after the reaction is over, place the reaction kettle in ice water to cool, then release the gas, and open the kettle; concentrate the pre-oxidized mixture under reduced pressure, and drop it into water or ether to precipitate when it becomes thick. Collect the precipitate and freeze-dry to obtain pre-oxidized lignin; 0.1g pre-oxidized lignin, 0.1gCuMgAlO x The catalyst and 2.4g of ethanol were put into the reactor and reacted at 300°C for 2h. After quantitative calculation, the total yield of monomer and dimer was 51.39C%. The overall yield of polymerization was 27.43C%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com