Modified polymer film and preparation method and application thereof

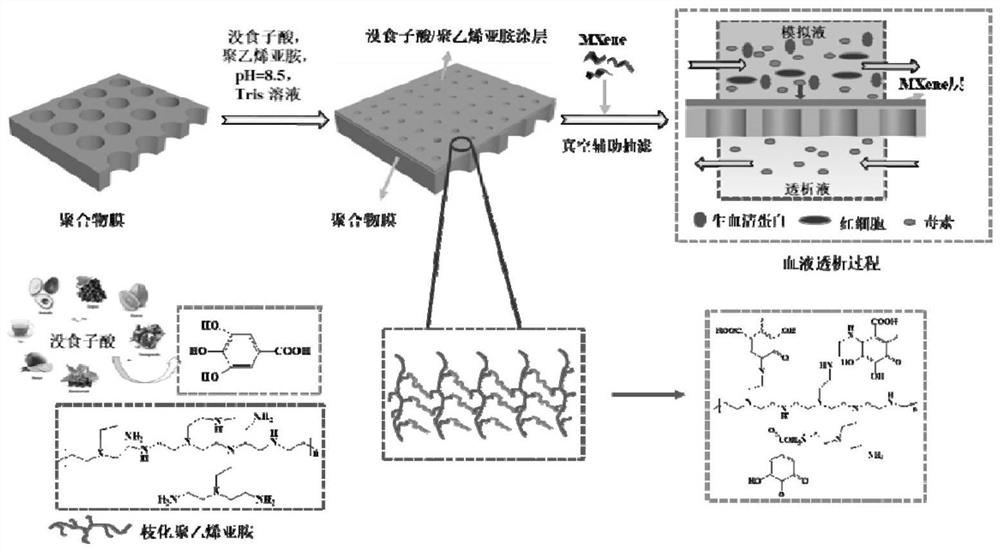

A polymer film and modification technology, which is applied in the direction of chemical instruments and methods, film, film technology, etc., can solve the problems of uneven coating film thickness, uneven coating film thickness, large loss of raw materials, etc., and achieve good anti-protein Effects of adsorption capacity and good antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] The preparation of embodiment 1 multilayer GA / MXene modified polymer film

[0114] (1)Na + Preparation of intercalated MXene: Mix 10mL 9mol / L hydrochloric acid solution with 0.5g lithium fluoride powder, stir for 5min to obtain an etching solution, add 0.5g titanium aluminum carbide powder to the etching solution and seal the container, at 35°C Stir for 24 hours for etching; after the etching, centrifuge at 12000 rpm for 5 minutes, pour off the supernatant, then add deionized water to wash, repeat the above steps 8-10 times; after pouring the supernatant for the last time, pour the suspension Add 10 mL of NaOH solution with a concentration of 0.05 g / mL and stir for 2 hours, then wash the precipitated powder with a large amount of deionized water until the pH of the solution after centrifugation is 7-8, and disperse the obtained slurry to a small amount Deionized water for standby to obtain a dispersion liquid, the concentration of the dispersion liquid is 0.01-0.05g / L....

Embodiment 2

[0121] The preparation of embodiment 2 multilayer GA / MXene modified polymer film

[0122] (1)Na + The preparation method of intercalation MXene, the synthesis of sulfanilic acid diazonium salt and the sulfonation modification of MXene are the same as in Example 1.

[0123] (2) Preparation of polymer membrane: polysulfone powder, porogen polyvinylpyrrolidone and N,N-dimethylacetamide solution were mixed in a round-bottomed flask at a mass ratio of 16:8:76, and heated at 60°C Under stirring for 8h, stand overnight for degassing. Then pour the above-mentioned casting solution on a glass plate, use a 200 μm scraper to shape it, and quickly immerse it in a constant temperature coagulation bath at 25°C to form a film, and soak the obtained polysulfone membrane in deionized water. PVDF membrane is denoted as M PVDF . Wherein, the N,N-dimethylacetamide solution is a pure solution with a mass concentration ≥ 99%.

[0124] (3) Preparation of GA-modified polymer film: prepare a buff...

Embodiment 3

[0126] The preparation of embodiment 3 multilayer GA / MXene modified polymer film

[0127] (1)Na + The preparation method of intercalation MXene, the synthesis of sulfanilic acid diazonium salt and the sulfonation modification of MXene are the same as in Example 1.

[0128] (2) Preparation of polymer membrane: Put polyethersulfone powder, porogen polyethylene glycol (molecular weight 10000) and N,N-dimethylacetamide solution in a round bottom according to the mass ratio of 14:10:76 Mix in the flask, stir at 60°C for 8h, and let stand overnight for degassing. Then pour the above-mentioned casting solution on a glass plate, use a 200 μm scraper to scrape it into shape, quickly immerse it in a constant temperature coagulation bath at 25°C to form a film, and soak the obtained polyethersulfone membrane in deionized water. The PVDF membrane is denoted as M PVDF .

[0129] (3) Preparation of GA-modified polymer film: prepare a final concentration of 2g / L Tris buffer solution, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com