High-heat-resistance electroplating-free PC/ASA alloy material for vehicle heat dissipation grid

A heat dissipation grill and alloy material technology, which is applied in the field of high heat-resistant electroplating-free PC/ASA alloy materials and PC/ASA alloy materials for vehicle heat dissipation grills. Thermal performance is not up to standard and other problems, to achieve the effect of improving toughness, increasing compatibility, and improving uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

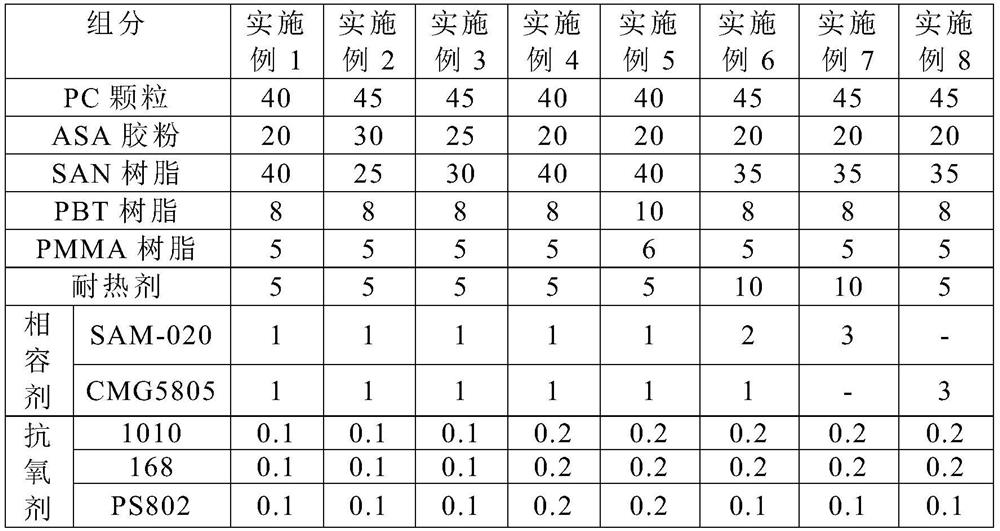

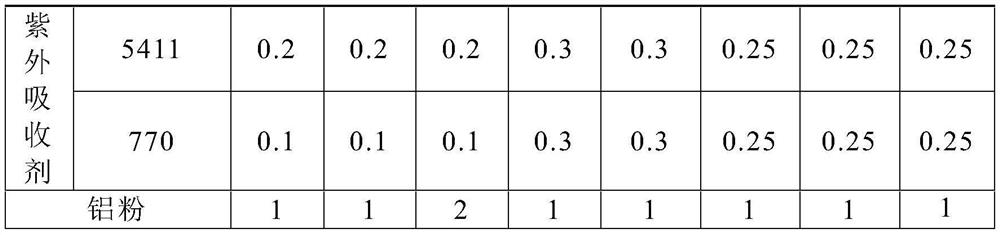

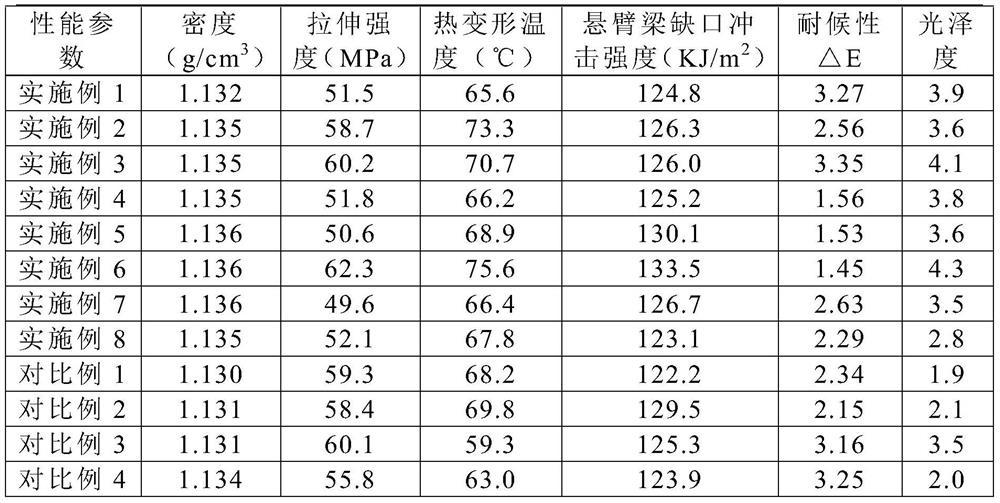

[0084] Examples 1-8 provide high heat-resistant electroplating-free PC / ASA alloy materials for vehicle radiator grilles, and the parts by weight of the raw material components are shown in Table 1. The PC resin used in Examples 1-8 is PC IR2200WW from Idemitsu, Taiwan, which is characterized by high fluidity; the ASA rubber powder is LP2065X from Pingyi Chemical; the SAN resin is NF2200 from Ningbo Taihua, which has medium fluidity and higher heat distortion temperature; PBT resin is PBT 4140-201D from Changchun, Taiwan; PMMA is IRD70 from Mitsubishi Rayon; 020 (PS-g-MAH) and CMG5805 (POE-g-MAH); aluminum powder is ECKARTDE MP 34-20C, particle size is 34μm; antioxidant is BASF 1010, 168 and PS802 compound antioxidant; ultraviolet absorption Agents are Cytec 5411 and 770.

[0085] The parts by weight of PC / ASA alloy material components in the embodiment 1-8 of table 1

[0086]

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com