Sound absorbing, flame-retardant and flame-retardant wall cloth and preparation method thereof

A technology of wall covering and polypropylene, which is applied in the manufacture of fire-resistant and flame-retardant filaments, non-woven fabrics, and rayon. It can solve problems such as poor flame-retardant and wear-resistant properties, violent combustion, and endangering the safety of indoor personnel. , to achieve the effect of improving viscosity, increasing compatibility and enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

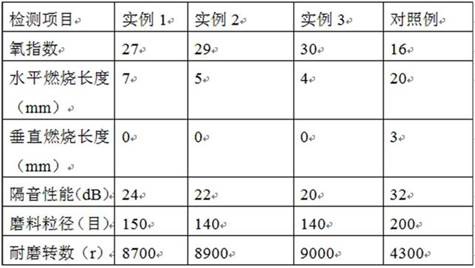

Examples

preparation example Construction

[0045] Preparation of the mixture:

[0046] Weigh the corn stalk fiber and put it into a pulverizer for pulverization, and mix the pulverized product with a sodium hydroxide solution with a concentration of 0.5 mol / L and a potassium permanganate solution with a concentration of 0.3 mol / L at a mass ratio of 1:10:4 Finally, put it into a water bath, stir and mix to obtain a mixed solution;

[0047] Preparation of pretreated corn stover fiber:

[0048] Raise the temperature of the above-mentioned water bath to 90-100°C, heat preservation pre-oxidation treatment for 40-60 minutes, filter and separate the filter residue after the pre-oxidation treatment, and obtain the filter residue, magnesium chloride solution with a concentration of 2mol / L and chlorine with a concentration of 1mol / L The zinc chloride solution was mixed according to the mass ratio of 1:7, placed on a shaker for oscillating reaction for 1 to 2 hours, then filtered, and the filter residue was obtained by separatio...

example 1

[0058] Preparation of the mixture:

[0059] Weigh the corn stalk fiber and put it into a pulverizer for pulverization, and mix the pulverized product with a sodium hydroxide solution with a concentration of 0.5 mol / L and a potassium permanganate solution with a concentration of 0.3 mol / L at a mass ratio of 1:10:4 Finally, put it into a water bath, stir and mix to obtain a mixed solution;

[0060] Preparation of pretreated corn stover fiber:

[0061] Raise the temperature of the above-mentioned water bath to 90°C, heat the pre-oxidation treatment for 40 minutes, filter and separate the filter residue after the pre-oxidation treatment is completed, and combine the obtained filter residue and the magnesium chloride solution with a concentration of 2mol / L and the zinc chloride solution with a concentration of 1mol / L by Mix at a mass ratio of 1:7, place on a shaker to vibrate for 1 hour, filter, and separate to obtain a filter residue;

[0062] Mix the filter residue and deionize...

example 2

[0071] Preparation of the mixture:

[0072] Weigh the corn stalk fiber and put it into a pulverizer for pulverization, and mix the pulverized product with a sodium hydroxide solution with a concentration of 0.5 mol / L and a potassium permanganate solution with a concentration of 0.3 mol / L at a mass ratio of 1:10:4 Finally, put it into a water bath, stir and mix to obtain a mixed solution;

[0073] Preparation of pretreated corn stover fiber:

[0074] Raise the temperature of the above-mentioned water bath to 95°C, heat preservation and pre-oxidation treatment for 50 minutes, filter and separate the filter residue after the pre-oxidation treatment is completed, and obtain the filter residue and the magnesium chloride solution with a concentration of 2mol / L and the zinc chloride solution with a concentration of 1mol / L. Mixed at a mass ratio of 1:7, placed on a shaker and oscillated for 2 hours, filtered, and separated to obtain a filter residue;

[0075] Mix the filter residue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com