Electron beam surface modeling process of a cold plate with low resistance and enhanced heat transfer

A technology to strengthen heat exchange and molding process, applied in electron beam welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of single triangular groove microstructure, limited drag reduction effect, collapse of molding unit, etc. Simple and easy to control, improve the service life, and prevent the effect of collapse of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] A method for modeling the surface of an aluminum alloy aimed at the electron beam surface modeling process of the present invention, the specific steps are as follows:

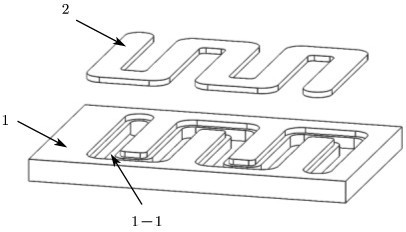

[0042] Process the base plate 1 and cover plate 2 in the cold plate according to the design drawings. The material is aluminum alloy. After the processing is completed, grooves 1-1 are formed on the base plate 1. Use alcohol, acetone and other solvents to clean the surface of the base plate 1 to be molded to remove oil stains , dry for later use;

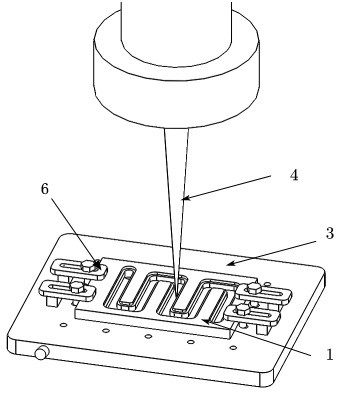

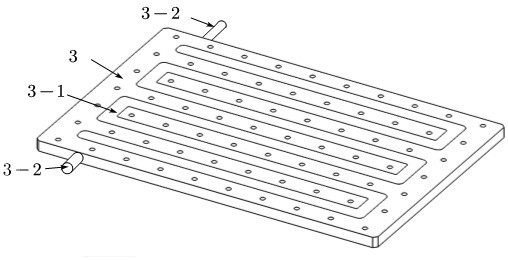

[0043] Install the substrate 1 into the vacuum electron beam welding machine, fix the substrate 1 with the cooling and fixing tool 3, adjust the distance between the substrate 1 and the electron gun 3 to be about 800mm, then close the vacuum chamber door, and extract the vacuum until the vacuum degree reaches 3 ×10 -3 After Pa, adjust the workpiece position to below the electron gun;

[0044] Carry out electron beam surface modeling on channel 1-1 according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com