Treatment method for edible film for meat preservation

An edible and acetic acid solution technology, which is applied to the preservation of meat/fish with a coating protective layer, can solve the problems of reducing the barrier and inhibition performance of edible films, low compactness and film-forming stability, and prolonged fresh-keeping period. , to achieve long-lasting and effective antibacterial and bactericidal effects, good water and gas barrier properties, and extended shelf life and storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

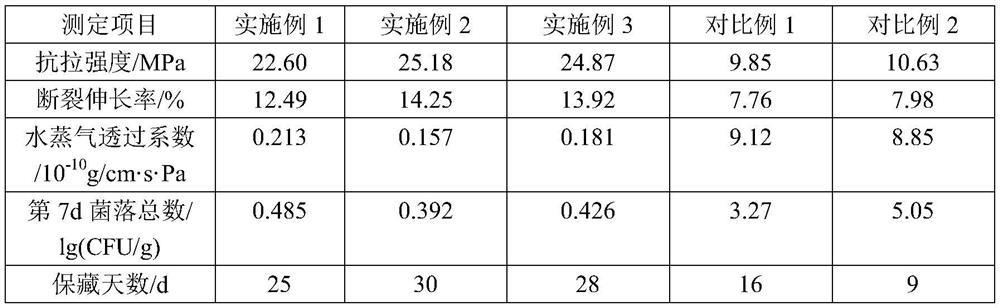

Examples

Embodiment 1

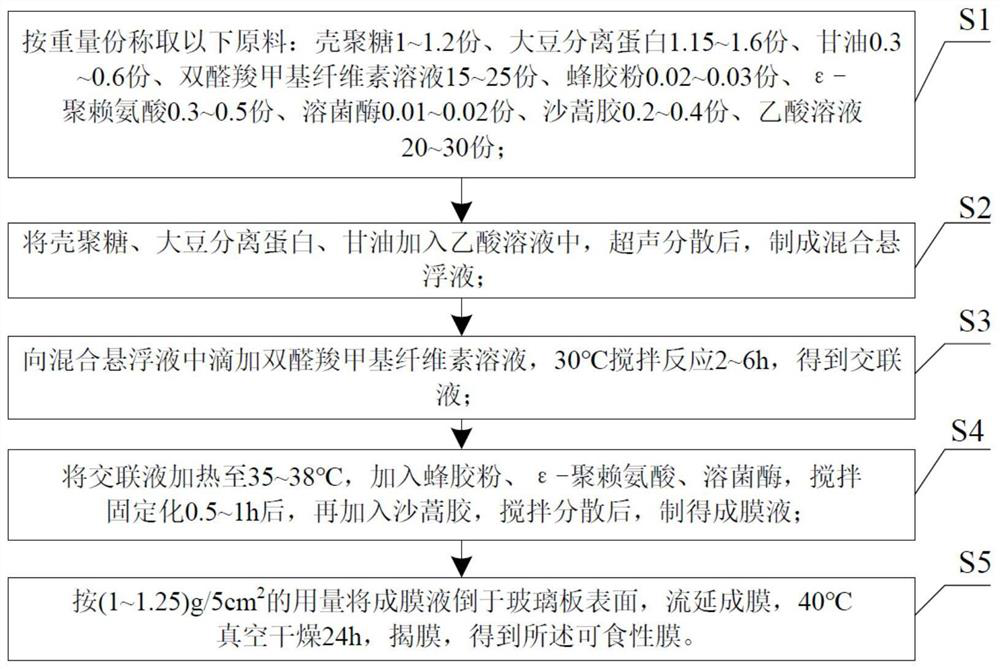

[0019] A method for preparing an edible film for meat preservation, comprising the following steps:

[0020] S1: Weigh 2g of chitosan, 2.3g of soybean protein isolate, 0.6g of glycerin, 35g of 8% dialdehyde carboxymethylcellulose solution, 0.04g of propolis powder, 0.6g of ε-polylysine, 0.02g of lysozyme, Artemisia gum 0.4g, 0.2% acetic acid solution 45g;

[0021] S2: Add chitosan, soybean protein isolate, and glycerin to 0.2% acetic acid solution, and ultrasonically disperse to make a mixed suspension;

[0022] S3: Add 8% dialdehyde carboxymethyl cellulose solution dropwise to the mixed suspension, stir and react at 30°C for 3 hours to obtain a cross-linking liquid;

[0023] S4: Heating the cross-linking solution to 35°C, adding propolis powder, ε-polylysine, and lysozyme, stirring and immobilizing for 0.5 hours, then adding Artemisia gum, stirring and dispersing, to prepare a film-forming solution;

[0024] S5: Pour 80g of film-forming solution on the surface of a glass pl...

Embodiment 2

[0026] A method for preparing an edible film for meat preservation, comprising the following steps:

[0027] S1: Weigh 2.2g of chitosan, 2.8g of soybean protein isolate, 0.9g of glycerin, 40g of 8% dialdehyde carboxymethylcellulose solution, 0.05g of propolis powder, 0.8g of ε-polylysine, and 0.03g of lysozyme , Artemisia gum 0.6g, 0.2% acetic acid solution 50g;

[0028] S2: Add chitosan, soybean protein isolate, and glycerin to 0.2% acetic acid solution, and ultrasonically disperse to make a mixed suspension;

[0029] S3: Add 8% dialdehyde carboxymethyl cellulose solution dropwise to the mixed suspension, stir and react at 30°C for 6 hours to obtain a cross-linking solution;

[0030] S4: Heating the cross-linking solution to 38°C, adding propolis powder, ε-polylysine, and lysozyme, stirring and immobilizing for 0.5 hours, then adding Artemisia gum, stirring and dispersing, to prepare a film-forming solution;

[0031] S5: Pour 80g of film-forming solution on the surface of a...

Embodiment 3

[0033] A method for preparing an edible film for meat preservation, comprising the following steps:

[0034] S1: Weigh 2.4g of chitosan, 3.2g of soybean protein isolate, 1.2g of glycerin, 50g of 8% dialdehyde carboxymethylcellulose solution, 0.06g of propolis powder, 1g of ε-polylysine, 0.04g of lysozyme, Artemisia gum 0.8g, 0.2% acetic acid solution 60g;

[0035] S2: Add chitosan, soybean protein isolate, and glycerin to 0.2% acetic acid solution, and ultrasonically disperse to make a mixed suspension;

[0036] S3: Add 8% dialdehyde carboxymethyl cellulose solution dropwise to the mixed suspension, stir and react at 30°C for 6 hours to obtain a cross-linking solution;

[0037] S4: Heating the cross-linking solution to 38°C, adding propolis powder, ε-polylysine, and lysozyme, stirring and immobilizing for 1 hour, then adding Artemisia gum, stirring and dispersing, to prepare a film-forming solution;

[0038] S5: Pour 100g of film-forming solution on the surface of a glass pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com