Silicone tube coating method and application

A silicone tube and coating technology, applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problem of easy peeling, weak adhesion between coating and silicone tube material, uneven film thickness, etc. problems, to achieve the effect of saving raw materials, easy mass production, and improved characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

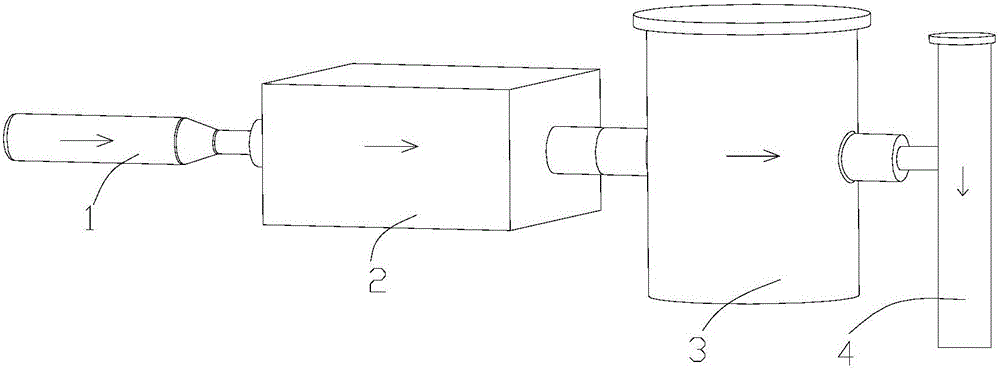

Image

Examples

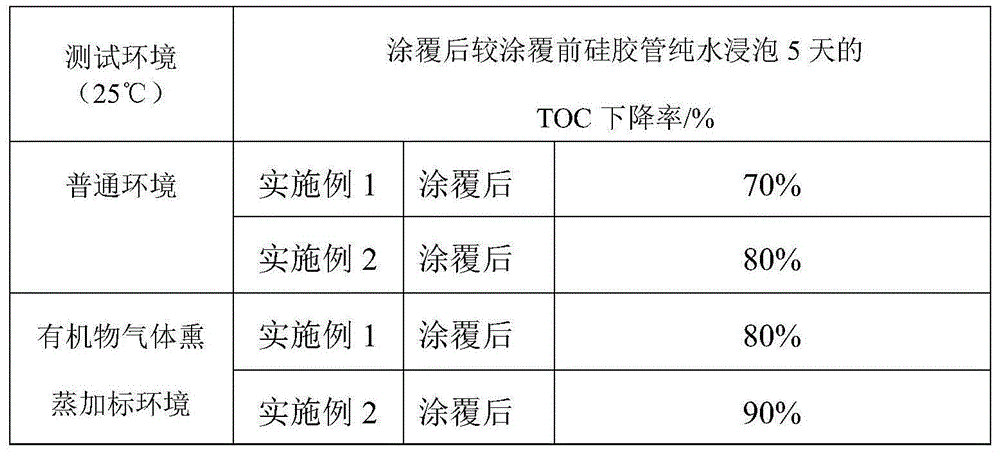

Embodiment 1

[0045] Select 30 silicone tubes with the size of ID10×OD14×L310mm., and keep 5 for comparison test before and after coating.

[0046] (1) cleaning, the silicone tube is repeatedly cleaned 3 times with distilled water;

[0047] (2) drying, drying at 70°C;

[0048] (3) mask, use ABS plastic parts to cover the inner wall of the silicone tube;

[0049] (4) Accompaniment film production, intercepting a section of silica gel tube of ID10×OD14×L310mm in this embodiment, and placing it in the deposition reaction chamber;

[0050] (5) Clean up the reaction site, remove impurities from the evaporation chamber, cracking chamber, and deposition chamber, and remove all possible impurities;

[0051] (6) The detection of pre-treatment reliability, the silicone tube of the mask is tested, mainly detecting the humidity of the silicone tube, the hygienic soaking of the silicone tube and the mechanical tensile strength of the silicone tube;

[0052] (7) Install racks, place 30 qualified silic...

Embodiment 2

[0057] Select 200 silicone tubes with the size of ID10×OD14×L310mm., and keep 10 for comparison test before and after coating.

[0058] (1) cleaning, the silicone tube is repeatedly cleaned 3 times with distilled water;

[0059] (2) drying, drying at 60°C;

[0060] (3) mask, use ABS plastic parts to cover the inner wall of the silicone tube;

[0061] (4) Accompaniment film production, intercepting a section of silica gel tube of ID10×OD14×L310mm in this embodiment, and placing it in the deposition reaction chamber;

[0062] (5) Clean up the reaction site, remove impurities from the evaporation chamber, cracking chamber, and deposition chamber, and remove all possible impurities;

[0063] (6) The detection of pre-treatment reliability, the silicone tube of the mask is tested, mainly detecting the humidity of the silicone tube, the hygienic soaking of the silicone tube and the mechanical tensile strength of the silicone tube;

[0064] (7) racking, placing 190 qualified silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com