Modified asphalt concrete capable of adsorbing carbon dioxide

A technology for adsorbing carbon dioxide and modifying asphalt, used in the field of asphalt concrete and modified asphalt concrete. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

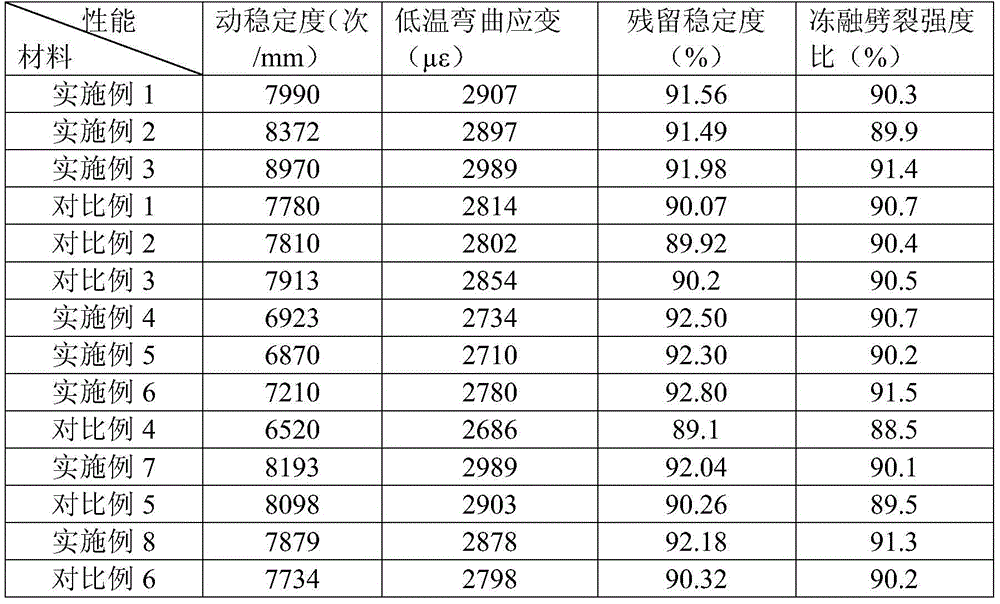

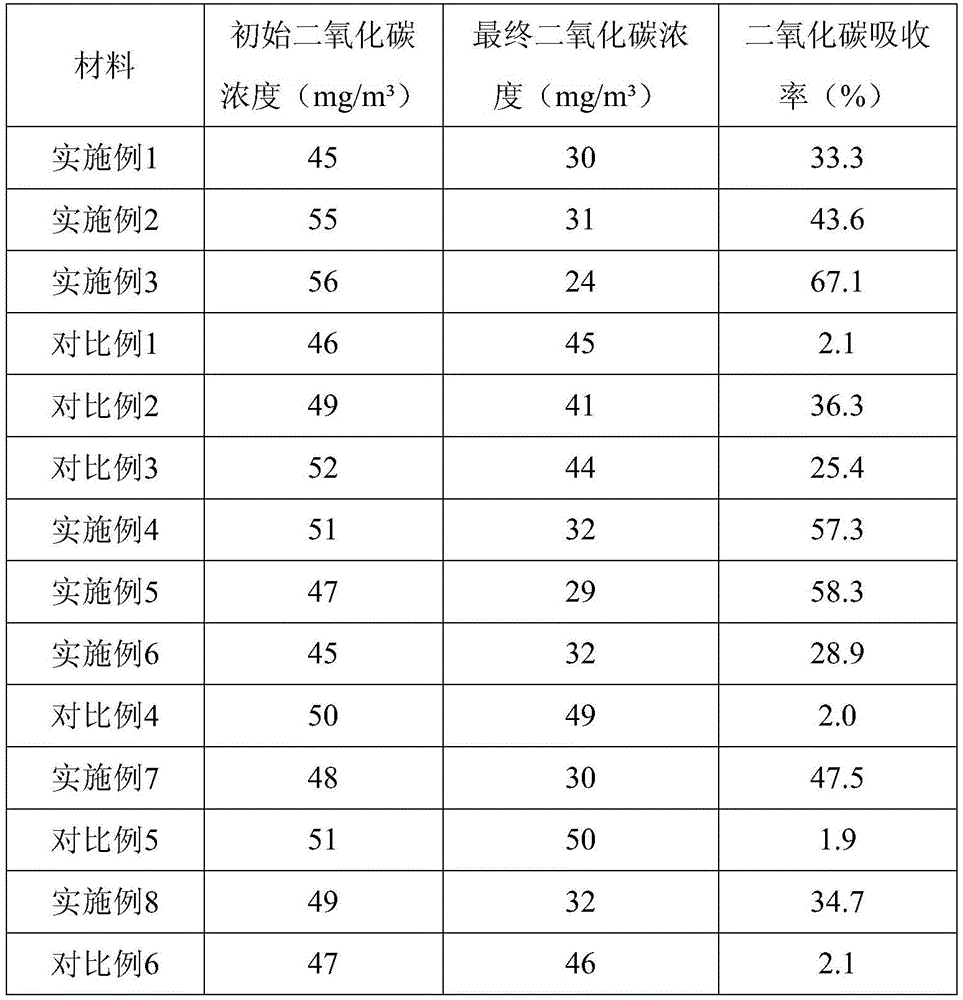

Examples

Embodiment 1

[0024] This embodiment provides a modified asphalt concrete capable of absorbing carbon dioxide, which is made of the following raw materials in parts by weight: 100 parts of ore material, 4.0 parts of asphalt, 0.4 part of ferropyroxene, 0.2 part of chlorite powder, and 0.01 part of nepheline powder 0.15 parts of dioctyl terephthalate, 0.04 parts of tert-butyl-o-acetyl citrate, 0.075 parts of fatty acid polyoxyethylene methyl ether, and 0.01 parts of N,N'-ethylene bisstearamide. The mineral material gradation type is AC-13 type. Described asphalt is road petroleum asphalt.

[0025] The preparation method of the present embodiment modified asphalt concrete comprises the following steps:

[0026] Step 1. Mix nepheline powder and calcium ferropyroxene powder evenly, add them into the ethanol solution with a mass percentage concentration of 20%, add fatty acid polyoxyethylene methyl ether after manual stirring for 15 minutes, and use a high-speed shearing machine to cut at 300r / m...

Embodiment 2

[0030] This embodiment provides a modified asphalt concrete capable of absorbing carbon dioxide, which is made of the following raw materials in parts by weight: 100 parts of ore material, 9.0 parts of asphalt, 2.4 parts of ferropyroxene, 2.0 parts of chlorite powder, and 0.05 parts of nepheline powder 1.0 part of dioctyl terephthalate, 0.2 part of tert-butyl-o-acetyl citrate, 0.5 part of fatty acid polyoxyethylene methyl ether, and 0.06 part of N,N'-ethylene bisstearamide. The mineral material gradation type is AC-13 type. The pitch is coal tar pitch.

[0031] The preparation method of the present embodiment modified asphalt concrete comprises the following steps:

[0032] Step 1. Mix nepheline powder and calcium ferropyroxene powder evenly, add them into the ethanol solution with a concentration of 30% by mass, stir manually for 15 minutes, add fatty acid polyoxyethylene methyl ether, and use a high-speed shearing machine to cut at 400r / min Stir at high speed for 20min, th...

Embodiment 3

[0036] This embodiment provides a modified asphalt concrete capable of absorbing carbon dioxide, which is made of the following raw materials in parts by weight: 100 parts of ore material, 6.0 parts of asphalt, 1.5 parts of ferropyroxene, 1.0 part of chlorite powder, and 0.03 parts of nepheline powder 0.5 part of dioctyl terephthalate, 0.15 part of tert-butyl-o-acetyl citrate, 0.2 part of fatty acid polyoxyethylene methyl ether, and 0.03 part of N,N'-ethylene bisstearamide. The mineral material gradation type is AC-13 type. The asphalt is SBS modified asphalt.

[0037] The preparation method of the present embodiment modified asphalt concrete comprises the following steps:

[0038] Step 1. Mix nepheline powder and calcium ferropyroxene powder evenly, add them into the ethanol solution with a concentration of 30% by mass, stir manually for 15 minutes, add fatty acid polyoxyethylene methyl ether, and use a high-speed shearing machine to cut at 400r / min Stir at high speed for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com