Cup chuck of substrate holding device and substrate holding device

A substrate holding and chucking plate technology, which is applied in the direction of semiconductor devices, electrolytic components, circuits, etc., can solve the problems of affecting product yield, prone to damage, and low thickness of electroplating layer, so as to improve convenience and efficiency and reduce damage Risk, the effect of reducing the exposed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to describe the technical content, structural features, achieved objects and effects of the present invention in detail, the following will be described in detail with reference to the embodiments and the drawings.

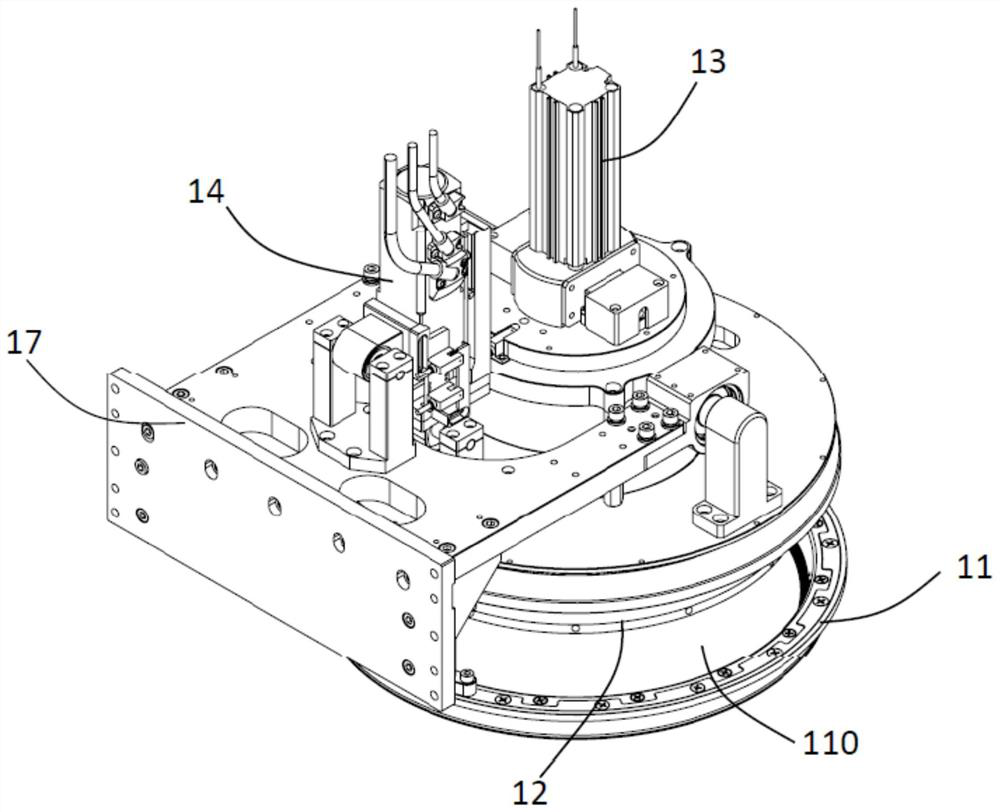

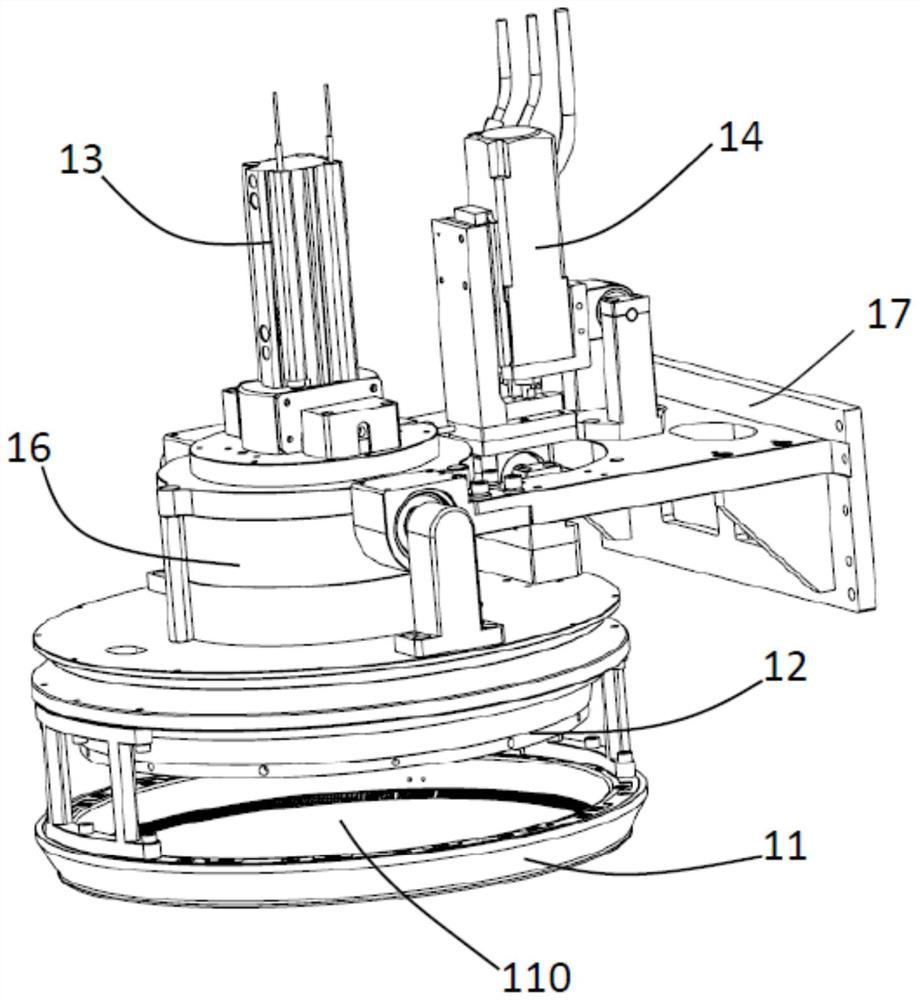

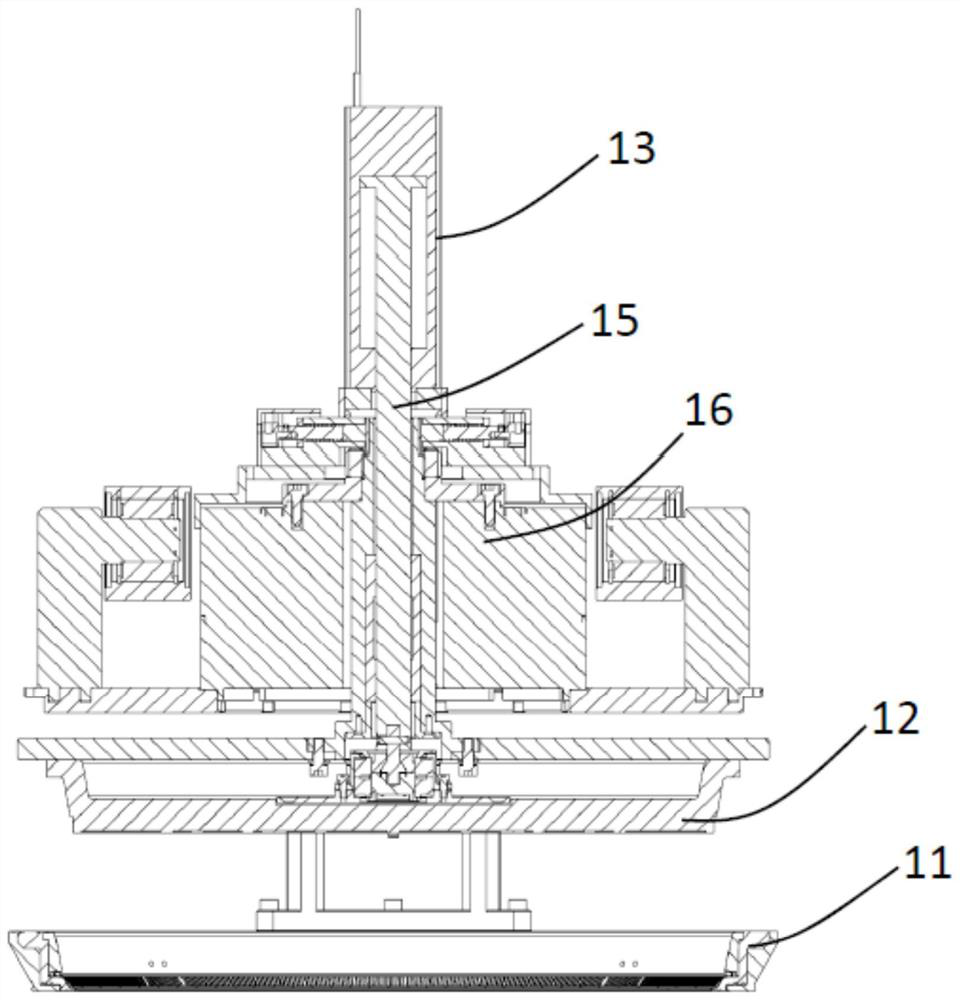

[0071] figure 1 and figure 2 A substrate holder in an embodiment of the present invention is shown. The substrate holding device includes components such as a cup chuck 11 , a chuck plate 12 , a chuck plate drive device 13 , an angle drive device 14 , a rotation drive device 16 , and a vertical drive device. A penetrating accommodating space 110 is formed in the center of the cup-shaped chuck 11 , and the accommodating space 110 is used for accommodating the substrate 10 . The chuck plate driving device 13 is connected to the chuck plate 12 through the universal joint shaft 15 to drive the chuck plate 12 to ascend and descend. Specifically, see image 3 , the chuck plate 12 is lifted to the substrate loading / unloading position away from the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com