Neodymium iron boron permanent magnet with corrosion preventing and abrasion resisting clad layer and preparing method of neodymium iron boron permanent magnet

An anti-corrosion and wear-resistant, permanent magnet technology, used in the manufacture of permanent magnets, magnets, magnetic objects, etc., can solve problems such as damage to the magnetic properties of corrosion-resistant magnets, and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing an NdFeB permanent magnet with an anti-corrosion and wear-resistant coating, which is used to prepare the above-mentioned NdFeB permanent magnet, the preparation method comprising the following steps:

[0023] S1: degreasing, grinding, polishing and cleaning the surface of the permanent magnet body 1;

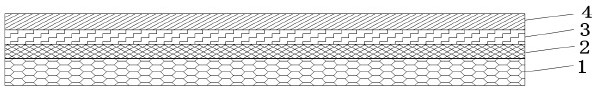

[0024] S2: The bonding layer 2, the inner protective layer 3 and the outer protective layer 4 are sequentially deposited on the surface of the permanent magnet body 1 by physical vapor deposition.

[0025] In an optional embodiment, Al in the preparation method 2 o 3 The purity of / Al / AlN can be greater than 99wt%, Al 2 o 3 The / Al / AlN film layer is used as the bonding layer. The film layer formed by the high-purity target effectively combines the inner and outer protective layers with the NdFeB permanent magnet body substrate, smoothes the surface defects of the substrate, improves the quality of the upper layer film, and also plays a role in c...

Embodiment 1

[0029] Fill the vacuum coating chamber with argon to a pressure of 0.5Pa, turn on the Al 2 o 3 Target, adjust the RF power to 180W, and pre-sputter the target for 30min. Degrease, grind, polish and clean the permanent magnet body 1 to deposit the bonding layer 2; then, fill the vacuum chamber with argon to a pressure of 0.7Pa, and the radio frequency power is 150W, and sputter on the bonding layer 2 by radio frequency Deposit the inner protective layer 3; finally, fill the vacuum chamber with argon gas until the pressure is 0.6Pa, and the radio frequency power is 100W, and deposit the outer protective layer 4 on the inner protective layer 3 by radio frequency sputtering; after testing, under this condition, the The performance of the composite film layer is as follows:

[0030] project performance total film thickness 4.3µm Film hardness 10.86GPa Corrosion protection performance At a temperature of 38°C and a salt water concentration of 3.5%, ...

Embodiment 2

[0032] Fill the vacuum coating chamber with argon to a pressure of 0.5Pa, turn on the Al 2 o 3 Target, adjust the RF power to 180W, and pre-sputter the target for 30min. Degrease, grind, polish and clean the permanent magnet body 1 to deposit the bonding layer 2; then, fill the vacuum chamber with argon to a pressure of 0.7Pa, and the radio frequency power is 150W, and sputter on the bonding layer 2 by radio frequency Deposit the inner protective layer 3; finally, fill the vacuum chamber with argon gas until the pressure is 0.6Pa, and the radio frequency power is 200W, and deposit the outer protective layer 4 on the inner protective layer 3 by radio frequency sputtering; after testing, under this condition, the The performance of the composite film layer is as follows:

[0033] project performance total film thickness 5.6µm Film hardness 19.37GPa Corrosion protection performance At a temperature of 38°C and a concentration of salt water of 3.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com