A kind of preparation method of magnetically immobilized lipase

A technology of immobilized lipase and magnetism, applied to biochemical equipment and methods, and enzymes immobilized on or in inorganic carriers, which can solve the problems of insufficient toughness of immobilized carriers, affecting lipase activity, and large grinding and screening losses, etc. problems, to achieve a wide range of environmental adaptation, increase toughness, and good lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

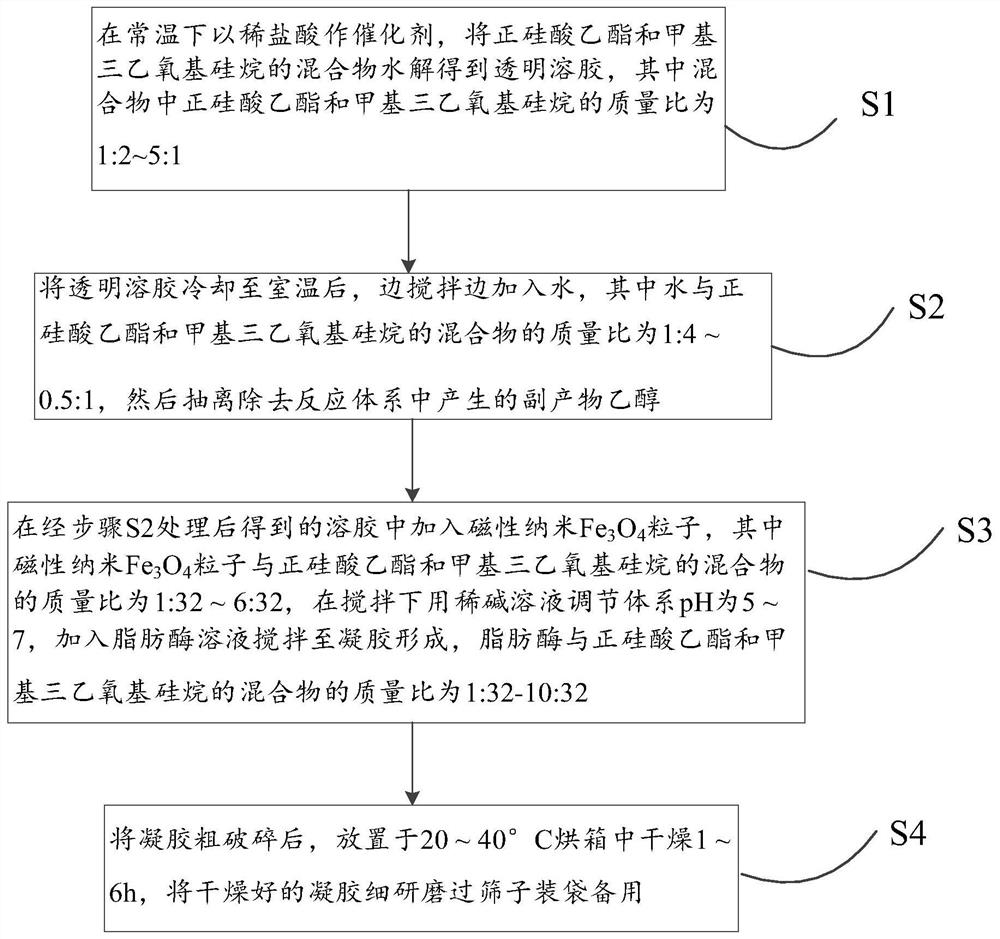

[0044] According to the preparation method of magnetically immobilized lipase of the present invention, steps S1 and S2 are the formation of sol precursors: weigh 6g and 26g, 16g and 16g, 22g and 10g, 26g and 6g, and 28g and 4g of TEOS and MTES respectively , under stirring, add 7g of 0.1mol / L dilute hydrochloric acid solution, the mass ratio of dilute hydrochloric acid solution to the mixture of TEOS and MTES is 7:32, after vigorous stirring for 20min, dilute acid at room temperature hydrolyzes the mixture of TEOS and MTES to form a clear transparent sol precursor , add 20g of water while stirring. The ethanol produced in the hydrolysis process was extracted under high vacuum, and the temperature of the water bath was increased to 37°C for suction filtration until the ethanol content in the sol was less than 6%.

[0045] Enter the formation of step S3 gel: add magnetic nano-Fe under stirring 3 o 4 Particles, adjust the pH of the system to 5 with dilute alkali solution, add ...

Embodiment 2

[0052] On the basis of steps S1 and S2 of Example 1, enter the formation of step S3 gel: add magnetic nano Fe under stirring 3 o 4 For the particles, use dilute alkali solution to adjust the system to different pH values in the range of 4-8, add lipase solution, and stir until gel is formed. Add 5g of magnetic nano-Fe 3 o 4 The mass ratio of the particles to the mixture of TEOS and MTES is 5:32, the dilute lye solution is a KOH solution with a concentration of 0.8mol / L, and 3ml of lipase stock solution is added.

[0053] Finally, enter the gel drying: After the gel is roughly broken, it is placed in an oven at 25°C and dried for 3 hours. Finely grind the dried gel through a 60-mesh sieve and bag it for later use.

[0054] Table 2 Experimental results at different pH values in the gel step

[0055]

[0056]

[0057] As shown in Table 2, when the mass ratio of TEOS and MTES is in the range of 1:2 to 5:1, the pH value during gelation can be expanded to 5-7. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com