A kind of multiphase transparent ceramic, multiphase transparent ceramic optical fiber and its preparation method and application

A technology of transparent ceramics and optical fibers, applied in glass manufacturing equipment, manufacturing tools, etc., to achieve the effects of rich luminescence spectrum, mild preparation conditions, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of multiphase transparent ceramics, the preparation steps are as follows:

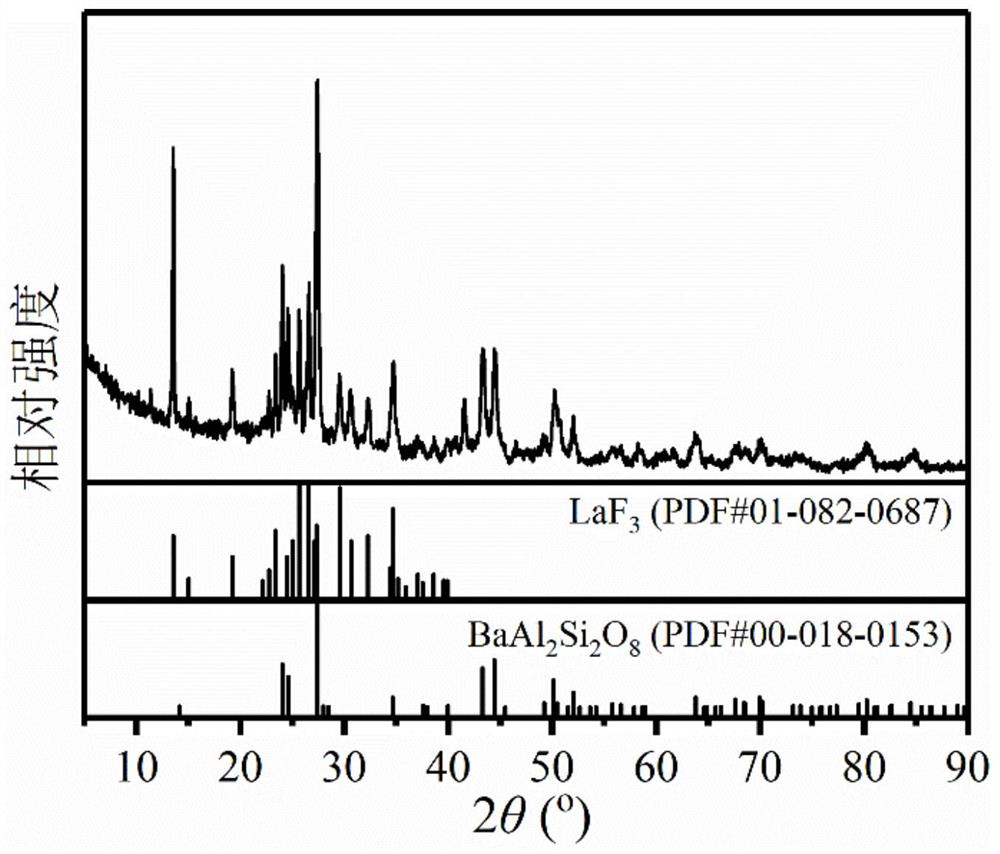

[0057] (1) Weigh the following component raw materials according to the following molar percentages: 25% SiO 2 , 25% BaCO 3 , 25% Al 2 o 3 , 24.5% LaF 3 , 0.5% Eu 2 o 3 Then fully grind with an agate mortar for 15 minutes;

[0058] (2) Put the uniformly mixed raw materials into an alumina crucible, place them in a high-temperature box furnace at 1500° C. for 30 minutes, and melt them to obtain molten glass;

[0059] (3) Pour molten glass into the formwork for cooling and forming to obtain a transparent glass block;

[0060] (4) Quickly transfer the glass to a muffle furnace, and anneal at 500°C for 48 hours to obtain a precursor glass;

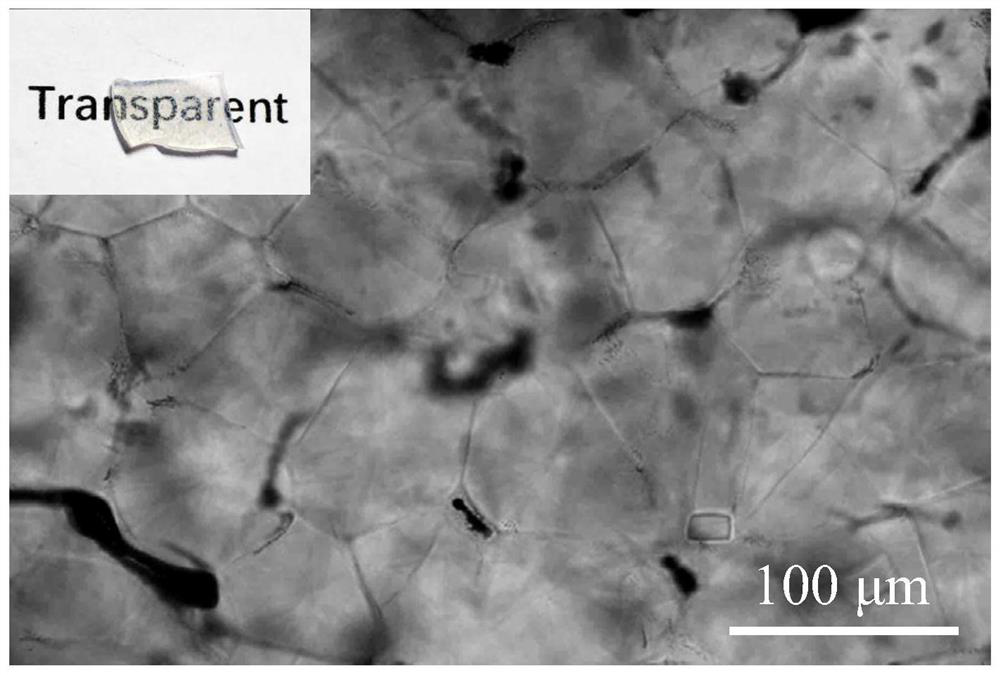

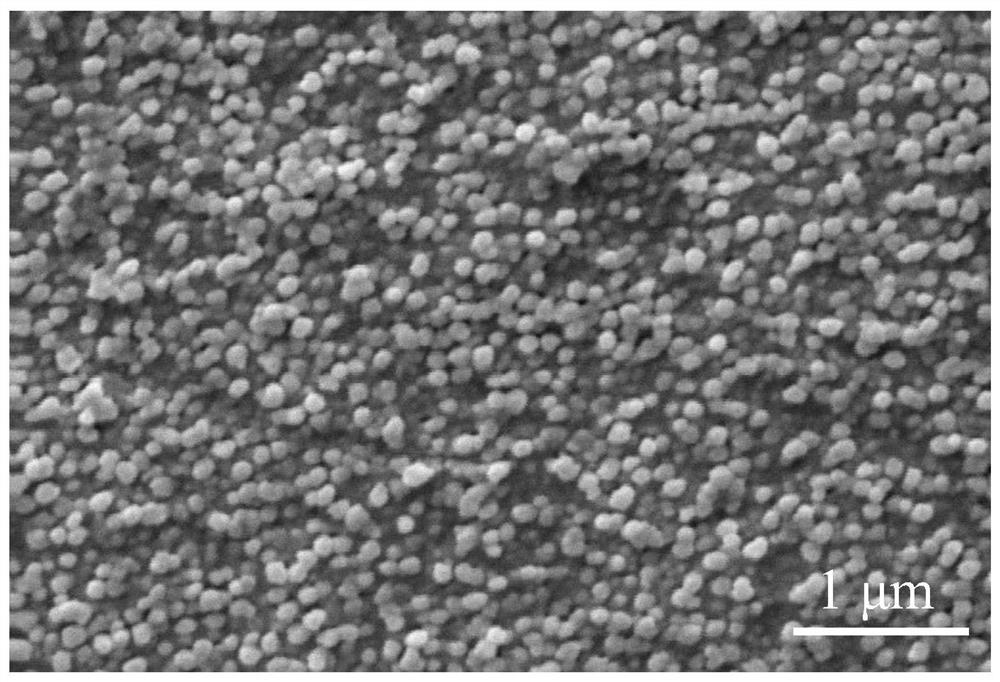

[0061] (5) Cut the precursor glass into the desired size, place it in a muffle furnace for heat treatment, the crystallization temperature is 830°C, hold the temperature for 4 hours, and take it out after returning to room temperatur...

Embodiment 2

[0074] A preparation method of multiphase transparent ceramics, the preparation steps are as follows:

[0075] (1) Weigh the following component raw materials according to the following mole percentage: 30% SiO 2 , 20% BaCO 3 , 30%Al 2 o 3 , 19.9% GdF 3 , 0.1% Eu 2 o 3 Then fully grind it with an agate mortar for 25 minutes;

[0076] (2) Put the uniformly mixed raw materials into an alumina crucible, place them in a high-temperature box furnace at 1550° C. for 60 minutes, and heat them for 60 minutes to melt to obtain a glass melt;

[0077] (3) Pour molten glass into the formwork for rapid cooling and forming to obtain a transparent glass block;

[0078] (4) Quickly transfer the glass to a muffle furnace, and anneal at 650°C for 96 hours to obtain a precursor glass;

[0079] (5) Cut the precursor glass into the desired size, place it in a muffle furnace for heat treatment, the crystallization temperature is 790°C, hold the temperature for 2 hours, and take it out aft...

Embodiment 3

[0090] A preparation method of multiphase transparent ceramics, the preparation steps are as follows:

[0091] (1) Weigh the following component raw materials according to the following molar percentages: 40% SiO 2 , 20% BaCO 3 , 25% Al 2 o 3 , 14% BaF 2 , 1% Eu 2 o 3 Then fully grind it with an agate mortar for 25 minutes;

[0092] (2) Put the uniformly mixed raw materials into an alumina crucible, place them in a high-temperature box furnace at 1500°C for 20 minutes, and heat them for 20 minutes to melt to obtain a molten glass;

[0093] (3) Pour molten glass into the formwork for cooling and forming to obtain a transparent glass block;

[0094] (4) Quickly transfer the glass to a muffle furnace, and anneal at 550°C for 96 hours to obtain a precursor glass;

[0095] (5) Cut the precursor glass into the desired size, place it in a muffle furnace for heat treatment, the crystallization temperature is 800°C, the holding time is 2.5h, and take it out after returning to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com