Neomycin sulfate production wastewater treatment method

A technology of neomycin sulfate and waste water production, which is applied in biological water/sewage treatment, water/sewage treatment, natural water treatment, etc. It can solve the problem of paralysis of anaerobic reactor, large amount of sludge loss and increased aeration rate, etc. problems, to achieve good social and economic benefits, high methane production rate, and reduced operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

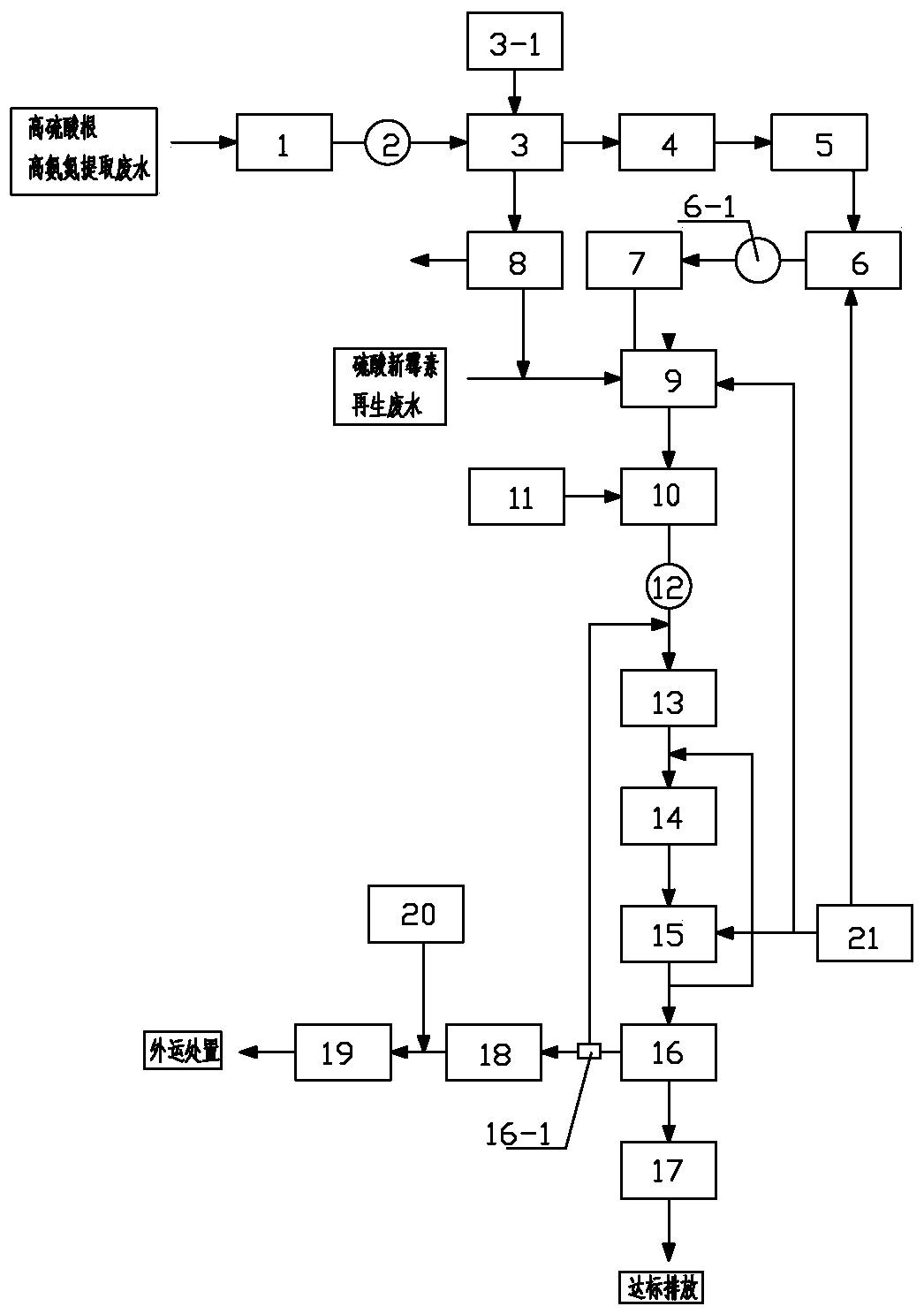

[0019] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and specific conditions.

[0020] When the present invention is implemented, it is provided by the following examples.

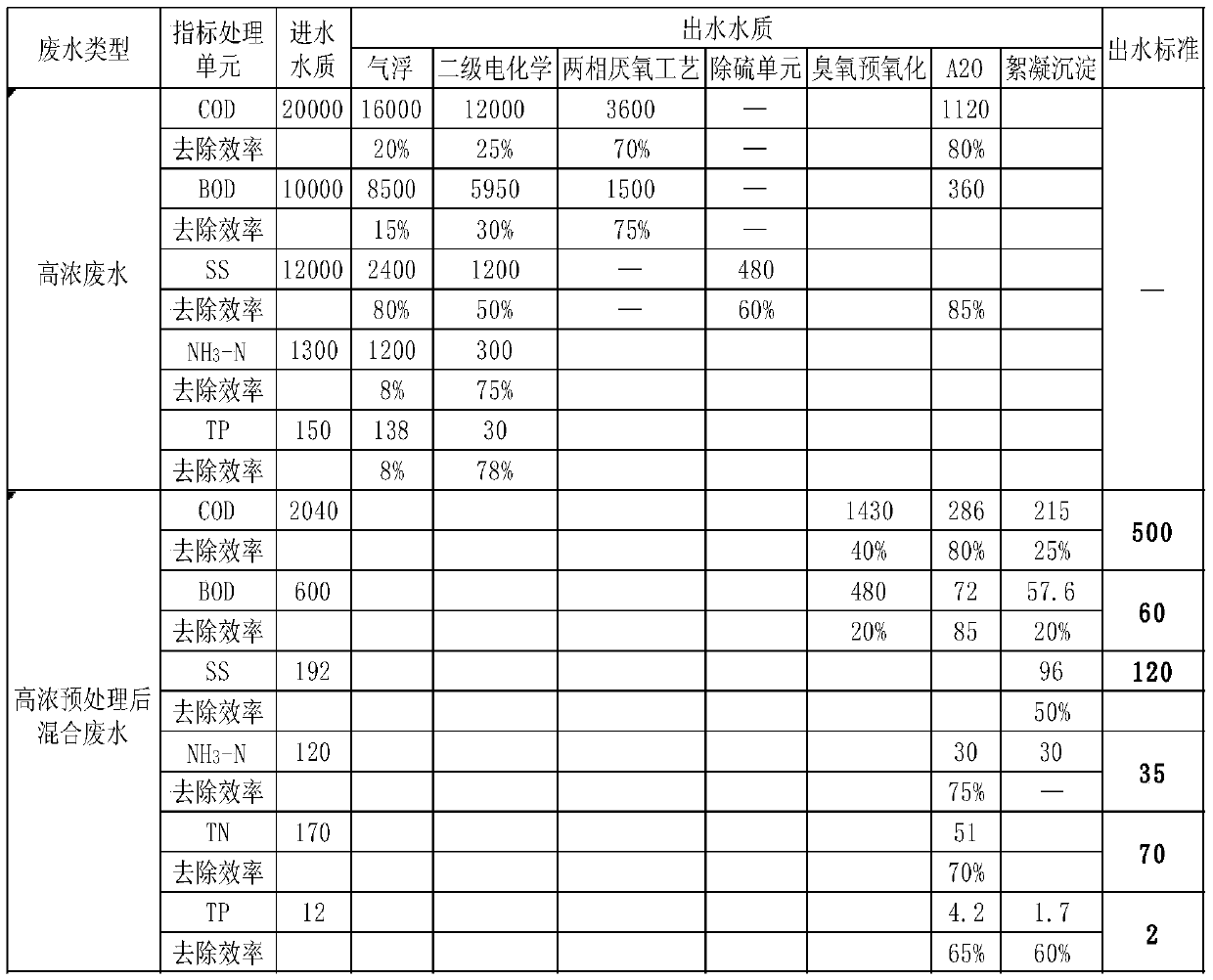

[0021] A kind of neomycin sulfate produces wastewater treatment method, comprises the following steps:

[0022] (1) Adjusting water quality and quantity: Many pharmaceutical productions are intermittent production, and the water quantity and quality fluctuate greatly, which is not conducive to the normal purification function of wastewater treatment equipment. In order to improve the impact capacity of sewage treatment facilities on organic matter load and reduce water quality fluctuations, a preset The regulating pool adjusts the water quantity and quality of the raw water. After the waste water with high sulfate and high ammonia nitrogen is removed through the grid well to remove larger suspended solids, floating solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com