Anti-thread-gluing thread grease and using method thereof

A thread grease and anti-galling technology, applied in the field of oil casing thread grease, can solve problems such as poor adhesion, inability to guarantee oil-based grease thread grease, and oil casing thread stiction failure, etc., and achieve good auxiliary lubrication and sealing , Good anti-sticking effect, enhance the effect of lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

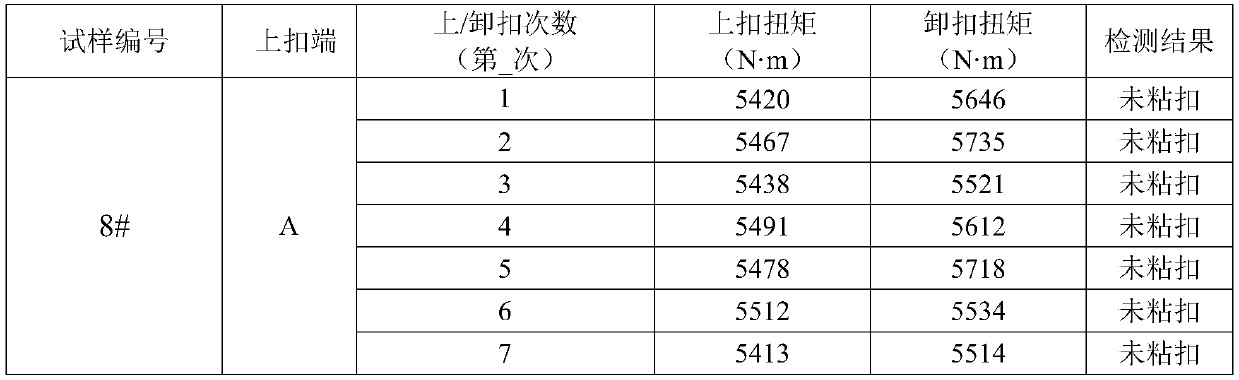

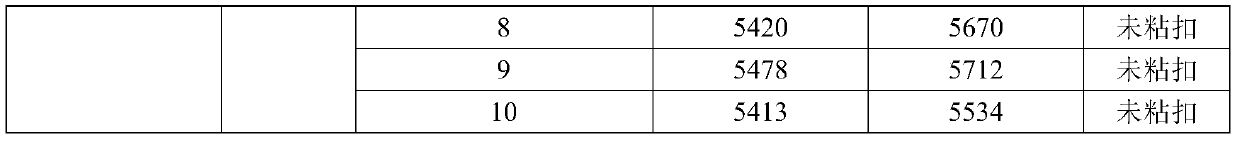

Examples

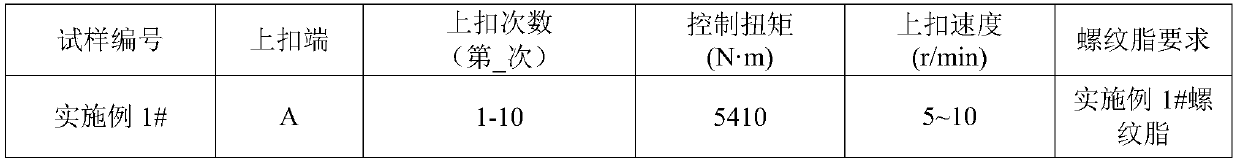

Embodiment 1

[0045] An anti-sticking thread grease of the present invention is composed of three components, wherein the mass ratio of the three components is A:B:C=1:2:4, in mass percentage, component A includes polyamide curing agent 40%, n-hexane 60%; component B includes epoxy resin 53%, nickel powder 9%, high-purity tungsten disulfide powder 33%, silicon nitride 3%, fumed silicon dioxide 2%; component C includes titanium Base grease 40%, microcrystalline graphite 5%, silicon carbide whisker 10%, graphite powder 16%, polytetrafluoroethylene powder 15%, nickel-titanium alloy 2%, zinc powder 12%.

[0046] According to the above component ratios, use the reaction kettle to mix the three components separately for use. When using, first clean the threaded surface of the oil casing, and then first apply component B evenly to the surface of the outer thread of the oil casing, and then apply Apply component A evenly to the surface of the threads that have been coated with component B above. Af...

Embodiment 2

[0058] An anti-sticking thread grease of the present invention is composed of three components, wherein the mass ratio of the three components is: A:B:C=0.8:1.6:4.2, in mass percentage, component A includes polyamide Curing agent 50% and n-hexane 50%; component B includes epoxy resin 47%, nickel powder 15%, high-purity tungsten disulfide powder 33%, silicon nitride 1%, fumed silicon dioxide 3%; component C Including titanium-based grease 50%, microcrystalline graphite 4%, silicon carbide whiskers 7%, graphite powder 15%, polytetrafluoroethylene powder 13%, nickel-titanium alloy 1% and zinc powder 10%.

[0059] According to the above component ratios, use the reaction kettle to mix the three components separately for use. When using, first clean the threaded surface of the oil casing, and then first apply component B evenly to the surface of the outer thread of the oil casing, and then apply Apply component A evenly to the surface of the outer thread of the oil casing that has ...

Embodiment 3

[0070] The novel anti-stick thread grease involved in the present invention is composed of three components, wherein the mass ratio of the three components is: A:B:C=1.1:2.2:4.2, in mass percentage, component A includes poly Amide curing agent 30% and n-hexane 70%; component B includes epoxy resin 53%, nickel powder 11%, tungsten disulfide powder 33.7%, silicon nitride 1.3% and fumed silicon dioxide 1%; component C includes Titanium-based grease 44%, microcrystalline graphite 4%, silicon carbide whisker 8%, graphite powder 16%, polytetrafluoroethylene powder 14%, nickel-titanium alloy 3%, zinc powder 11%.

[0071] According to the above component ratios, use the reaction kettle to mix the three components separately for use. When using, first clean the threaded surface of the oil casing, and then first apply component B evenly to the surface of the outer thread of the oil casing, and then apply Apply component A evenly to the surface of the outer thread of the oil casing that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com