Preparing method and application of Cr-Al-C series MAX phase coating

A coating, cr-c technology, applied in the field of preparation of Cr-Al-C MAX phase coating, can solve problems affecting battery power, stability and life, achieve excellent corrosion resistance and protection performance, and improve the degree of bonding , Improve the effect of interface conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

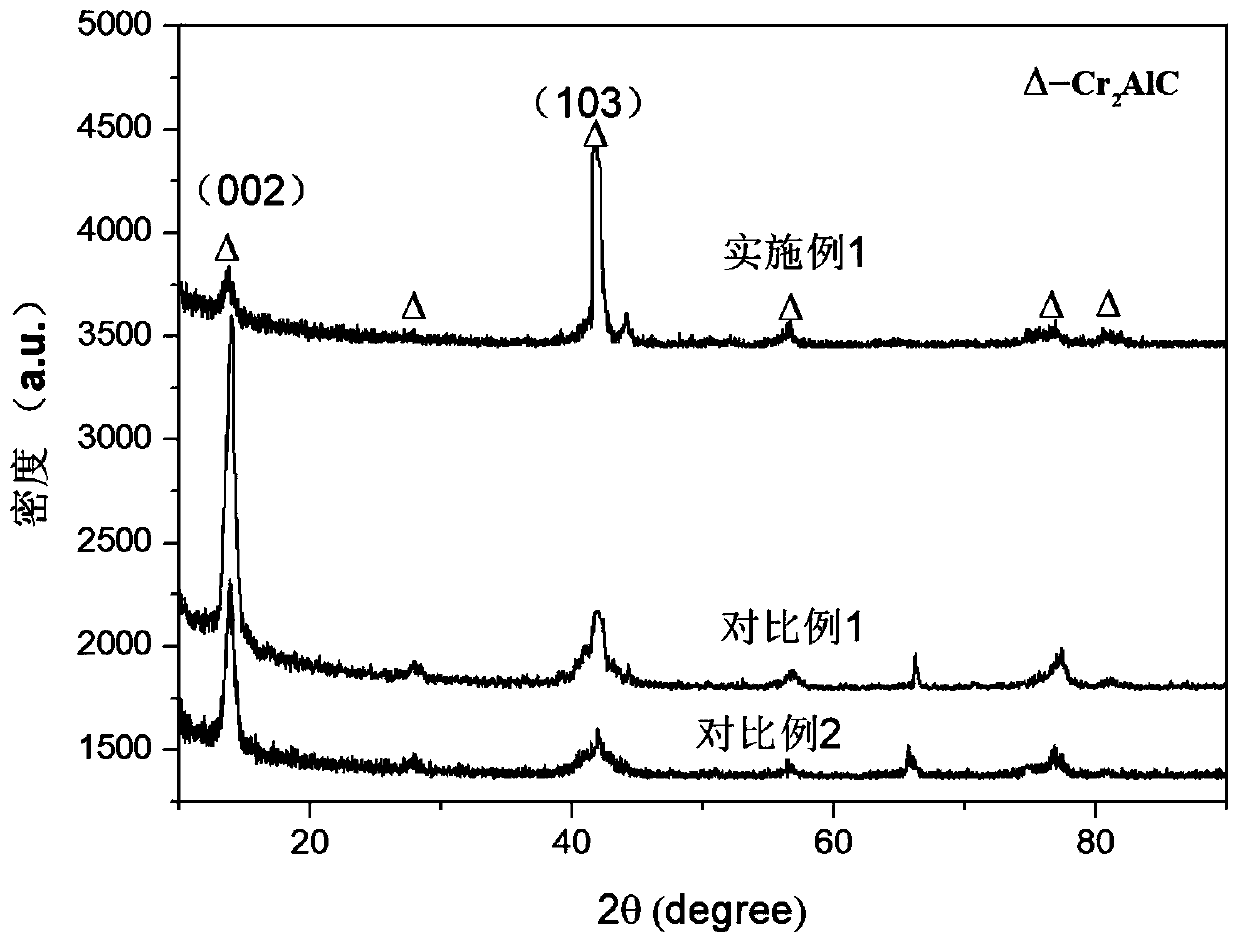

Embodiment 1

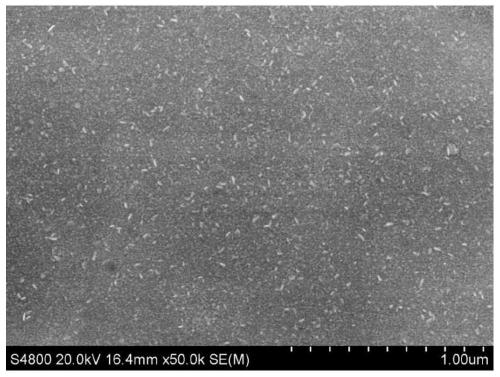

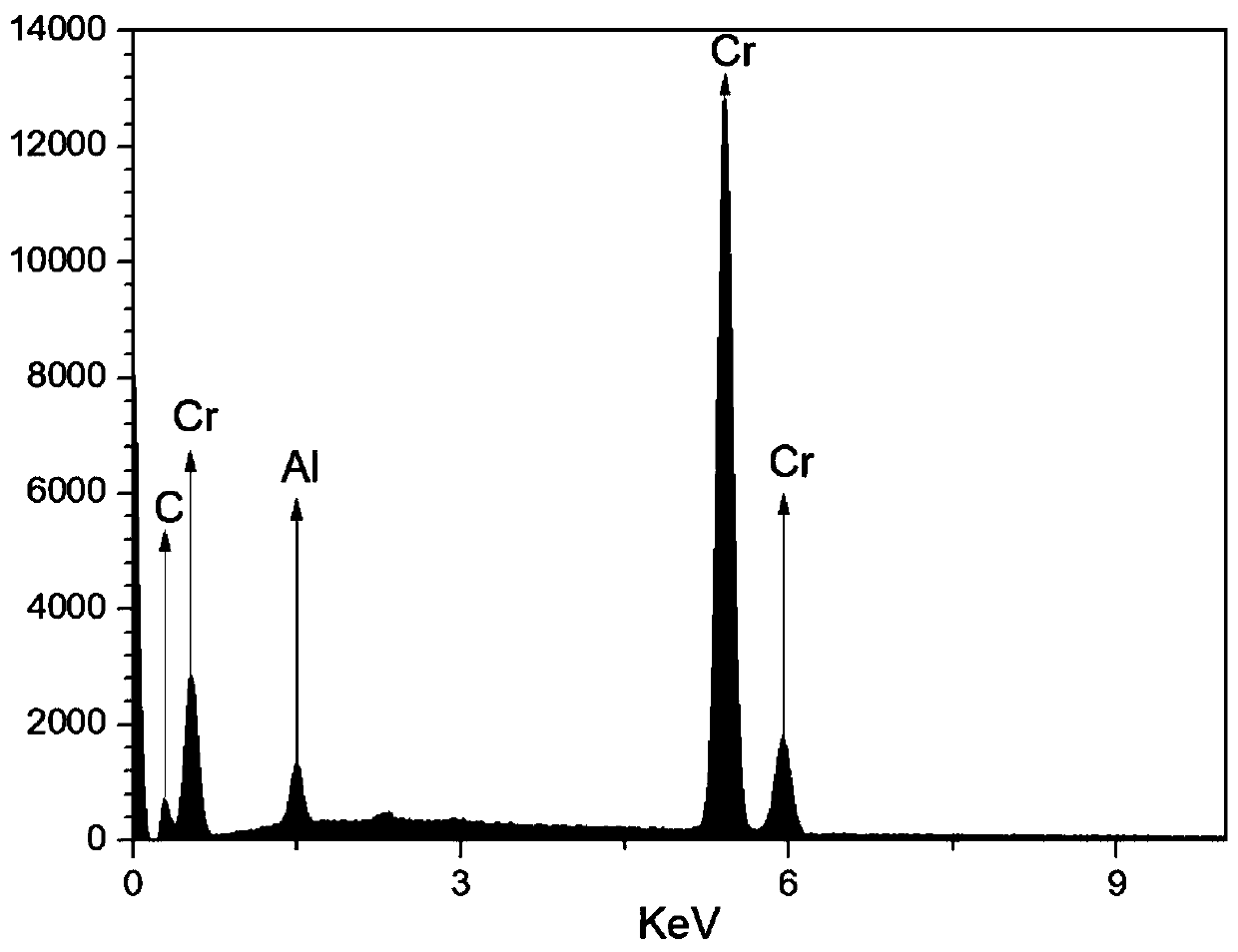

[0038] In this embodiment, the substrate is a 304 stainless steel bipolar plate used in a proton exchange membrane fuel cell, and the preparation method of the Cr-Al-C system MAX phase coating on the surface of the substrate is as follows:

[0039] (1) Put the substrate after cleaning, degreasing and drying into the cavity, and wait until the vacuum pressure in the cavity is 3.0×10 -5 Below Torr, 100 standard milliliters / minute of argon gas is introduced into the vacuum chamber, the linear anode ion source current is set to 0.3A, the substrate bias voltage is -100V, and the substrate is etched for 30 minutes with ionized argon ions.

[0040] (3) The Cr-C transition layer is deposited by arc ion plating technology, wherein the cathode arc target provides the Cr source, and the gas CH 4 Provide C source, arc target current is 90A, CH 4 The flow rate is 10 standard ml / min, the flow rate of argon gas is 300 standard ml / min, the bias voltage of the substrate is -200V, the deposition...

Embodiment 2

[0055] In this embodiment, the substrate is a 316L stainless steel bipolar plate used in a proton exchange membrane fuel cell, and the preparation method of the Cr-Al-C system MAX phase coating on the surface of the substrate is as follows:

[0056] (1) Put the 316L stainless steel substrate after cleaning, degreasing and drying into the cavity, and wait until the vacuum pressure in the cavity is 3.0×10 -5 Below Torr, 100 standard milliliters / minute of argon gas is fed into the vacuum chamber, the linear anode ion source current is set to 0.3A, the substrate bias voltage is -200V, and the substrate is etched with ionized argon ions for 20 minutes.

[0057] (2) The Cr-C transition layer is deposited by arc ion plating technology, wherein the cathode arc target provides the Cr source, and the gas CH 4 Provide C source, arc target current is 65A, CH 4 The flow rate is 10 standard ml / min, the flow rate of argon gas is 300 standard ml / min, the bias voltage of the substrate is -200...

Embodiment 3

[0061] In this embodiment, the substrate is a 309 stainless steel bipolar plate used in a proton exchange membrane fuel cell, and the preparation method of the Cr-Al-C system MAX phase coating on the surface of the substrate is as follows:

[0062] (1) Put the 309 stainless steel substrate after cleaning, degreasing and drying into the cavity, and wait until the vacuum pressure in the cavity is 3.0×10 - 5 Below Torr, 100 standard milliliters / min of argon gas was introduced into the vacuum chamber, the linear anode ion source current was set to 0.3A, the substrate bias was -150V, and the substrate was etched for 30 minutes with ionized argon ions.

[0063] (3) The Cr-C transition layer is deposited by arc ion plating technology, wherein the cathode arc target provides the Cr source, and the gas CH 4 Provide C source, arc target current is 90A, CH 4 The flow rate is 10 standard ml / min, the flow rate of argon gas is 300 standard ml / min, the bias voltage of the substrate is -150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com