Preparation method for large-length welding spot-free copper-chromium-zirconium contact wire

A copper-chromium-zirconium, contact wire technology, used in cable/conductor manufacturing, conductive materials, metal/alloy conductors, etc., can solve problems such as inability to uniformly organize, uneven deformation of wire blanks, and differences in product organization, and achieve shortening. The effect of heating and heating time, weakening precipitation strengthening effect, and controlling product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

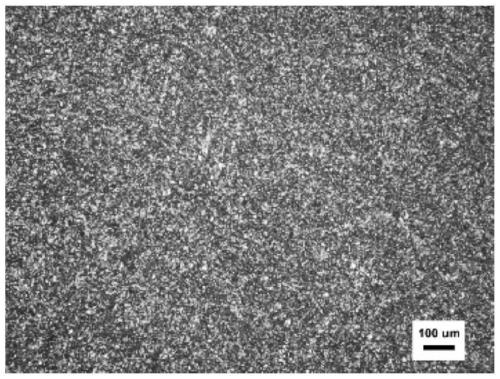

[0039] The composition of copper chromium zirconium is: Cr: 0.95wt%, Zr: 0.12wt%, Mg: 0.04wt%, Si: 0.02wt%, Cu: balance; the process flow of copper chromium zirconium contact wire:

[0040] 1) Casting: The smelting temperature is controlled at 1250-1350°C, the cooling water pressure is 0.3MPa, the copper-chromium-zirconium alloy wire billet diameter is 30mm, the casting speed is 45mm / min, and the weight of the drawing wire billet is 2.3t. ;

[0041] 2) Cold processing: the 30mm wire blank is processed to 20mm by 5 cold drawing, the total deformation is 55.56%, and the deformation of each pass is controlled between 10% and 20%;

[0042] 3) Annealing treatment: Anneal the wire billet after cold working, the temperature is controlled at 750°C, the holding time is 3h, and it is cooled with the furnace;

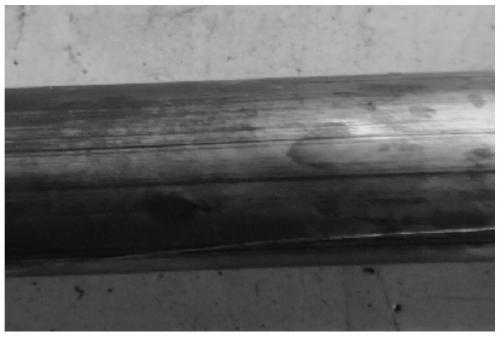

[0043] 4) Continuous extrusion: TLJ630 continuous extrusion machine is used for processing. Tooling mold and preheated copper rod are preheated at 650°C for 2 hours. First, 5m preh...

Embodiment 2

[0051] The composition of copper chromium zirconium is: Cr: 0.8wt%, Zr: 0.1wt%, Mg: 0.03wt%, Si: 0.04wt%, Cu: balance; the process flow of copper chromium zirconium contact wire:

[0052] 1) Casting: The melting temperature is controlled at 1250-1350°C, the cooling water pressure is 0.3MPa, the diameter of the copper-chromium-zirconium alloy wire billet produced by the upward continuous casting method is 35mm, the casting speed is 40mm / min, and the weight of the drawing wire billet is 2.3t. ;

[0053] 2) Cold processing: the 35mm wire blank is processed to 25mm by 5 cold drawing, the total deformation is 48.98%, and the deformation of each pass is controlled between 10-20%;

[0054] 3) Annealing treatment: Anneal the wire billet after cold working, the temperature is controlled at 800°C, the holding time is 2h, and it is cooled with the furnace;

[0055] 4) Continuous extrusion: TLJ630 continuous extrusion machine is used for processing. Tooling mold and preheated copper rod ...

Embodiment 3

[0062] The composition of copper chromium zirconium is: Cr: 1.2wt%, Zr: 0.05wt%, Mg: 0.02wt%, Si: 0.03wt%, Cu: balance; the process flow of copper chromium zirconium contact wire:

[0063] 1) Casting: The smelting temperature is controlled at 1250-1350°C, the cooling water pressure is 0.3MPa, the diameter of the copper-chromium-zirconium alloy wire billet produced by the upward continuous casting method is 35mm, the casting speed is 50mm / min, and the weight of the drawing wire billet is 2.1t. ;

[0064] 2) Cold processing: the 35mm wire blank is processed to 28mm by 3 cold drawing, the total deformation is 36%, and the deformation of each pass is controlled between 10% and 20%;

[0065] 3) Annealing treatment: annealing the cold-processed wire blank, the temperature is controlled at 600°C, the holding time is 5h, and cooled with the furnace;

[0066] 4) Continuous extrusion: TLJ630 continuous extrusion machine is used for processing. Tooling mold and preheated copper rod are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com