Drill bit housing steel and preparation method thereof

A steel and shell technology, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of short service life and wear resistance defects of drill bit shells, and improve high temperature mechanical properties, hardness and wear resistance properties, good strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

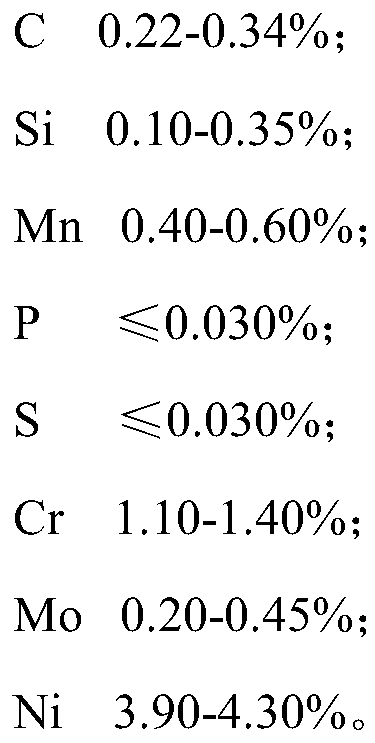

[0050] A steel material for the drill bit shell, the chemical composition of which is shown in Table 3.

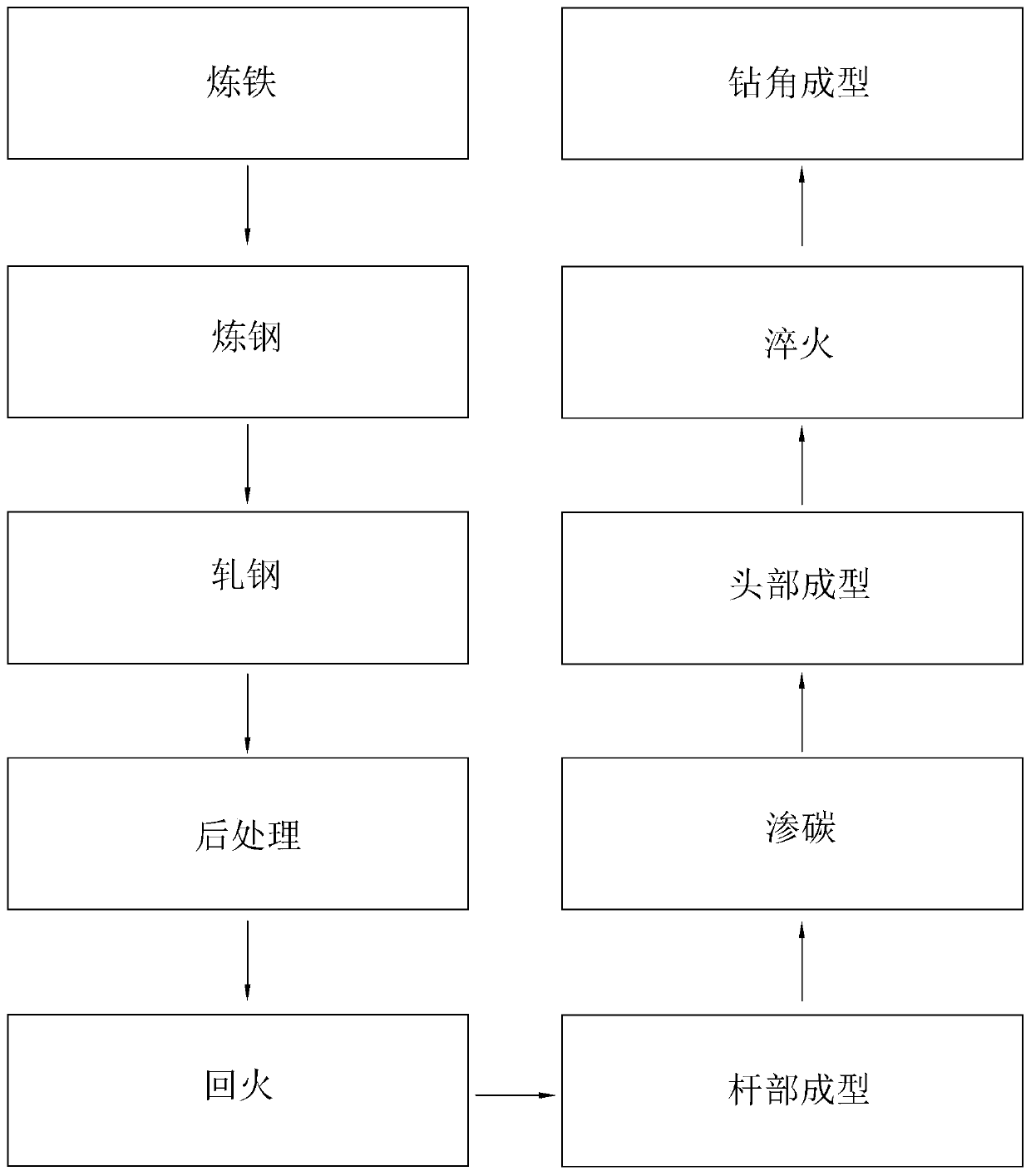

[0051] Such as figure 1 Shown, the preparation method of this drill bit shell comprises the following steps:

[0052] S1, ironmaking, reducing sintered ore to molten iron in a blast furnace, the temperature of the blast furnace is 1500-1700°C;

[0053] S2, steelmaking, alloy raw materials are weighed according to the weight ratio of each element, and the alloy raw materials are put into molten iron in the converter or electric furnace to make steel. The temperature of the ladle is 1550-1650 ° C. The molten steel after smelting is in the LF refining furnace and VD furnace for refining treatment, the refined molten steel is poured into continuous casting slabs in the continuous casting machine, and the steelmaking-continuous casting cycle is 6h;

[0054] S3, steel rolling, the temperature of the heating furnace is 900-1100°C, the continuous casting slab is heated by the he...

Embodiment 2

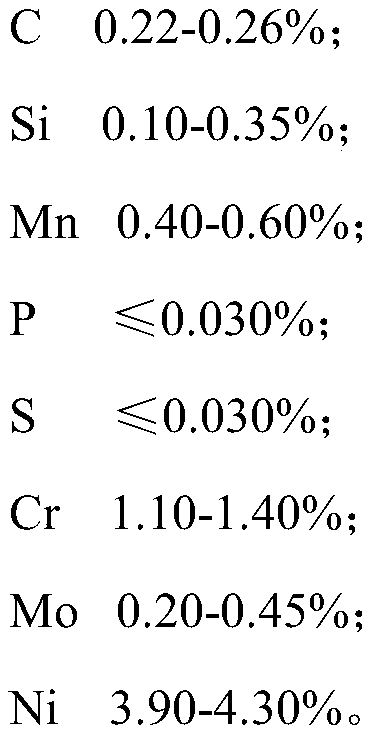

[0071] The difference from Example 1 is that the chemical composition of the drill bit shell steel is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com