A kind of preparation method of heat-resistant liquid high activity and high stability modified aluminum powder

A high-stability, high-activity technology, applied in the treatment of dyed polymer organic compounds, explosives, fibrous fillers, etc., can solve the problem of the inability of modified aluminum powder to resist, and achieve improved dispersion and suspension, low equipment requirements, and technology. The effect of green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

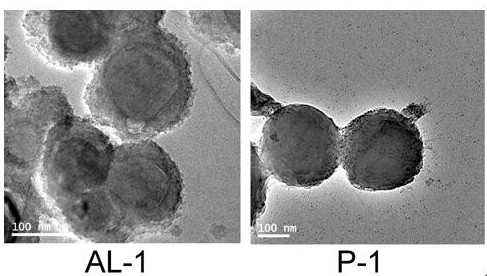

[0028] At normal temperature and pressure, 5 g of nano-aluminum powder was added to 100 mL of water, and ultrasonically dispersed for 0.5 min to obtain an aluminum powder dispersion; then 0.5 g of dopamine and 0.5 g of polysuccinimide were added to the aluminum powder dispersion in sequence , adjust the pH value to 6, stir and react at room temperature for 24 hours, and form a dense copolymer coating layer on the surface of the aluminum powder; then filter, wash, and vacuum-dry to obtain the modified aluminum powder, which is marked as AL-1. The content of the cladding layer is 8.5 wt.% of the mass of the aluminum powder.

[0029] Stability of modified aluminum powder: After heating the modified aluminum powder in a mixture of ethyl acetate and water (volume ratio: 1:4) at 60°C for 1 hour, no hydrogen gas is generated, and the microscopic appearance of the modified aluminum powder remains unchanged. change.

[0030] Determination of ignition power, burning rate and ignition d...

Embodiment 2

[0032] At normal temperature and pressure, 8.75 g of nano-aluminum powder was added to 200 mL of water, and ultrasonically dispersed for 0.7 min to obtain an aluminum powder dispersion; then 0.3 g of tea polyphenols and 0.4 g of polyacrylamide were added to the aluminum powder dispersion in sequence , adjusted the pH value to 8, stirred and reacted at room temperature for 6 hours, and formed a dense copolymer coating layer on the surface of the aluminum powder; then filtered, washed, and dried in vacuum to obtain a modified aluminum powder, marked as AL-2. The content of the cladding layer is 8.2 wt.% of the mass of the aluminum powder.

[0033] Stability of modified aluminum powder: After heating the modified aluminum powder in a mixture of ethyl acetate and water (volume ratio 1:4) at 70°C for 1 hour, no hydrogen gas is produced.

[0034] Determination of ignition power, burning rate and ignition delay of modified aluminum powder: see Table 1.

Embodiment 3

[0036]At normal temperature and pressure, 3 g of micron aluminum powder was added to 50 mL of water and ultrasonically dispersed for 0.6 min to obtain an aluminum powder dispersion; then 0.4 g of tannic acid and 0.2 g of polyaniline were added to the aluminum powder dispersion in sequence, Adjust the pH value to 6.5, stir and react at room temperature for 10 hours, and form a dense copolymer coating layer on the surface of the aluminum powder; then obtain the modified aluminum powder (AL-3) through suction filtration, washing, and vacuum drying. The content is 3.3 wt.% of the mass of aluminum powder.

[0037] Stability of modified aluminum powder: After heating the modified aluminum powder in a mixture of ethyl acetate and water (volume ratio 1:4) at 80°C for 1 hour, no hydrogen gas is produced.

[0038] Determination of ignition power, burning rate and ignition delay of modified aluminum powder: see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com