An advanced treatment system and method for water reuse in fine chemical tail water

An advanced treatment, fine chemical technology, applied in water/sewage treatment, water/sewage multi-stage treatment, special compound water treatment, etc., can solve the problem of low removal efficiency of organic pollutants, and improve sustainability and degradation efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The three-stage electrocatalytic Fenton / electrochemical double oxidation coupling device + reverse osmosis (RO) system combination process is used to treat the tail water of triazole nitrogen-containing heterocyclic compound pesticide production, and realize the full reuse of pesticide wastewater.

[0064] Pesticide production tail water inflow 500m 3 / d, COD=500mg / L, TDS concentration 4000mg / L.

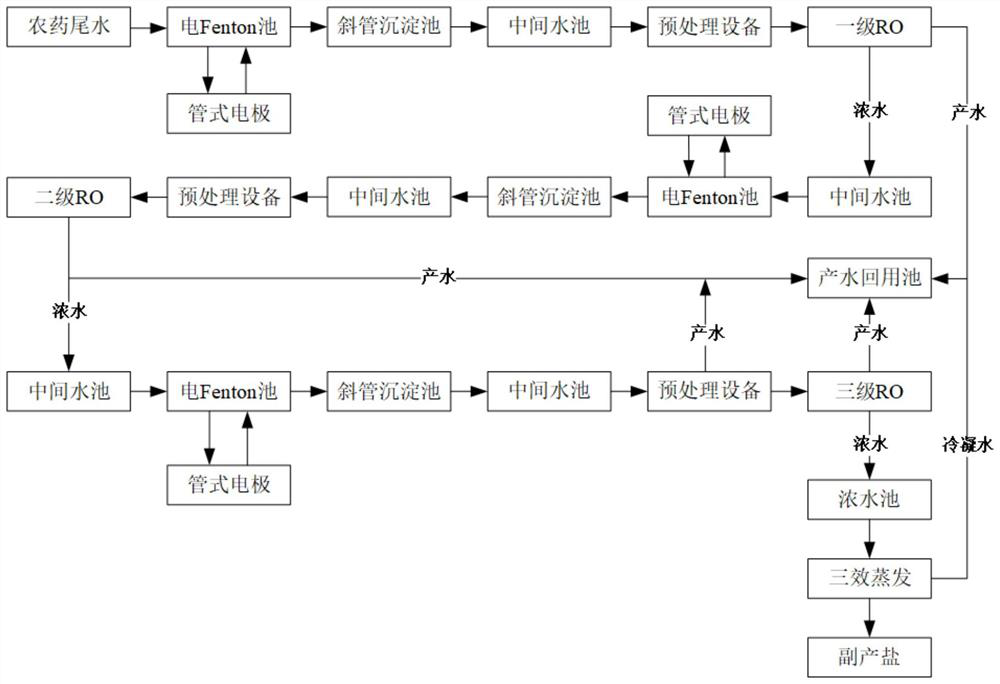

[0065] A method for advanced treatment of pesticide tail water reuse, such as figure 2 Shown:

[0066] Step 1. At 500m 3 Add sulfuric acid to the pesticide tail water to adjust the pH to 3.0-4.0;

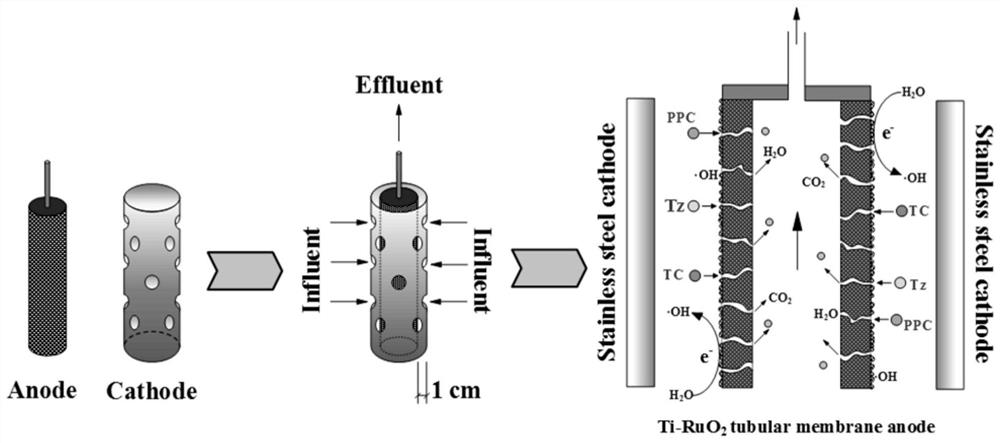

[0067] Step 2. Electrocatalytic Fenton oxidation process: Pesticide tail water is circulated in the double oxidation reaction tank, and at the same time, the electrocatalytic porous composite iron electrode is used to generate Fe 2+ , the electrocatalytic Fenton oxidation current density is 15mA / cm 2 , when the reaction time reaches 4h, open the electrochemical oxidation unit ...

Embodiment 2

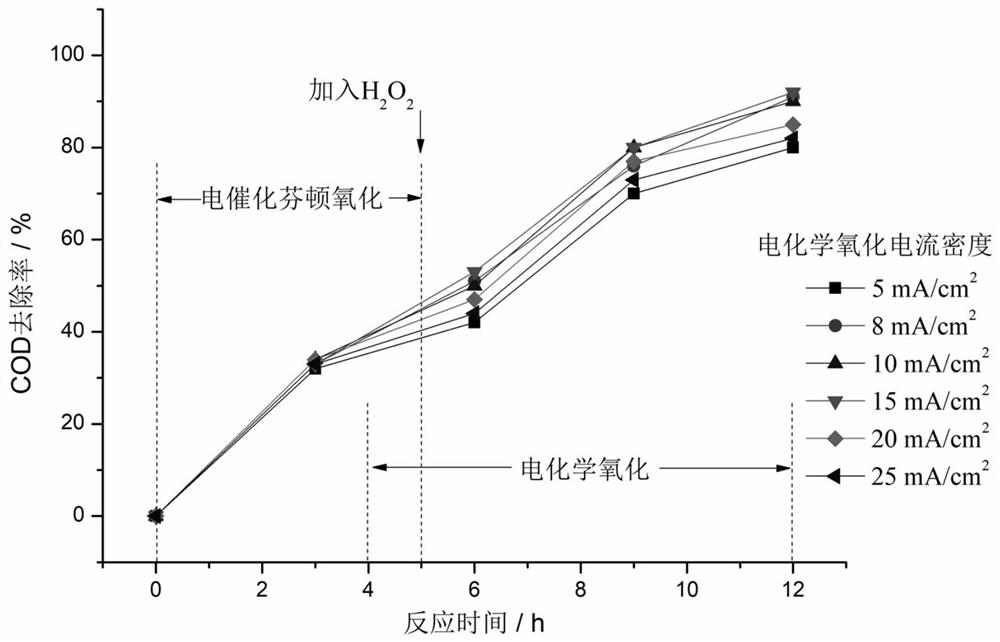

[0087] In this embodiment, when the other conditions are basically the same as in Example 1, only different current densities are used in the electrochemical oxidation step: 5mA / cm 2 , 8mA / cm 2 、15mA / cm 2 、20mA / cm 2 、25mA / cm 2The COD removal efficiency of the primary treatment (step 1 to step 3) under the conditions (only the COD removal efficiency of the double oxidation process of the primary treatment is examined), such as image 3 As shown, when the current density is low, the 12hCOD removal efficiency of the pesticide tail water is relatively low; the current density is 8-15mA / cm 2 When , the COD removal efficiency of pesticide tail water is high, and when the current density is increased, the COD removal efficiency will decrease, and to a certain extent, with the increase of current density, the COD removal rate will gradually decrease.

Embodiment 3

[0089] Other conditions in this embodiment are basically the same as in Example 1, the difference is that only the COD removal efficiency of the double oxidation process of primary treatment is investigated, and the electrocatalytic Fenton oxidation current density in the electrocatalytic Fenton oxidation process of step 2 is respectively 5mA / cm 2 , 8mA / cm 2 、10mA / cm 2 、15mA / cm 2 、20mA / cm 2 、25mA / cm 2 , other process conditions are the same, the COD removal efficiency after primary treatment (step 1 to step 3), such as Image 6 As shown, in the 12h of "electrocatalytic Fenton oxidation - electrochemical oxidation", when the electrocatalytic Fenton current density rises from 5 to 20mA / cm 2 During the process, the COD removal rate continued to increase, and when the current density continued to rise from 20 to 25mA / cm 2 , the COD removal rate decreased slightly. This shows that when the Fe released in the system 2+ When the concentration is within a certain range, it can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com