Bone trabecula porous tantalum dental implant and preparation method thereof

A technology for dental implants and porous tantalum, which is used in dental implants, dentistry, additive manufacturing, etc., can solve the problems of poor implantation stability of dental implants, difficult to prepare dental implants, easy oxidation mechanical properties, etc., and achieve stable implantation. Good stability and long-term stability, excellent osteoconductive and osteoinductive properties, and the effect of shortening the implantation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing a trabecular porous tantalum dental implant described in the above scheme, comprising the following steps:

[0044] The three-dimensional model of the trabecular bone porous tantalum dental implant is constructed by using the modeling software, and the additive manufacturing is carried out with pure tantalum or medical tantalum alloy powder as the raw material according to the constructed model.

[0045] The present invention has no special requirements on the modeling software, and modeling software well known to those skilled in the art can be used.

[0046] After obtaining the three-dimensional model, the present invention preferably converts the three-dimensional model into the format required by the printing equipment and imports it into the additive manufacturing equipment, and then uses pure tantalum or tantalum-containing alloy medical tantalum alloy powder as raw material for printing; in the present inv...

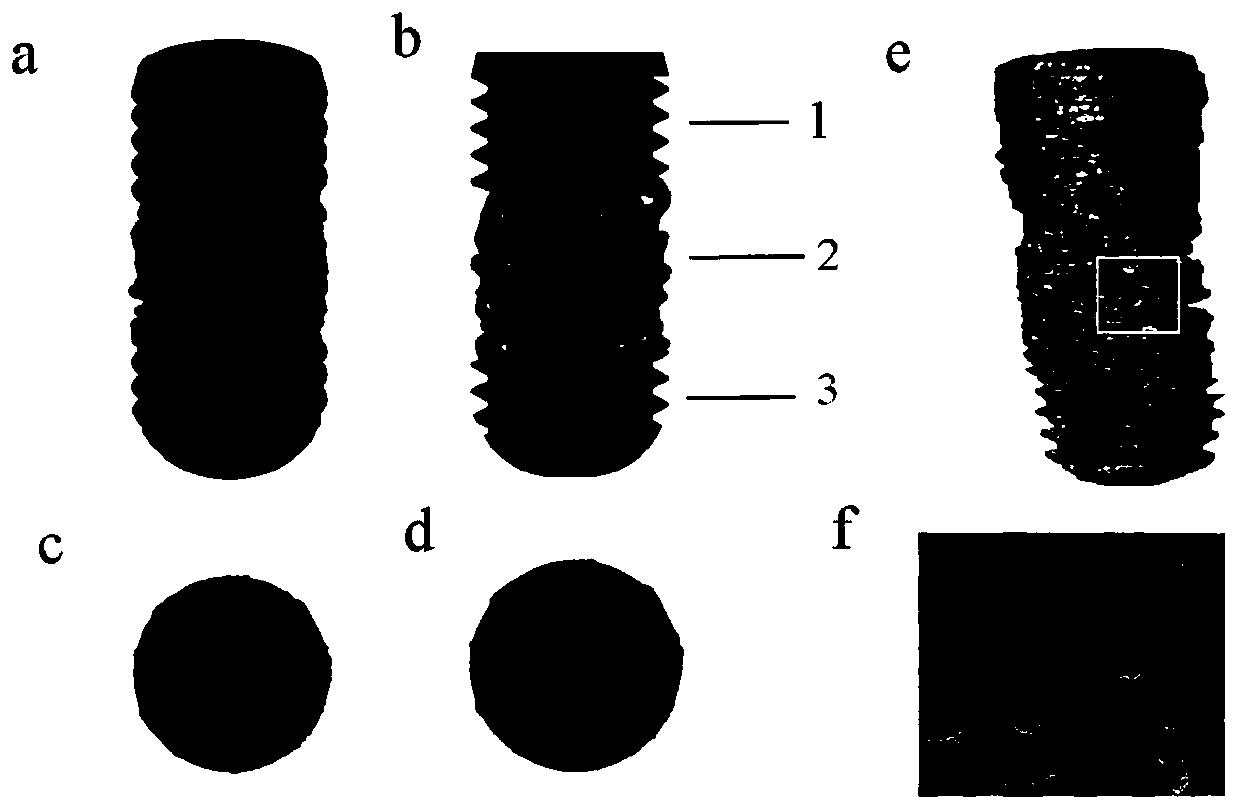

Embodiment 1

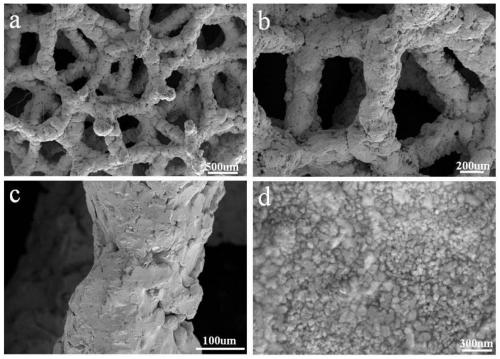

[0056] Use professional modeling software to design the structure of the three functional areas, and build a three-dimensional model of the trabecular bone porous tantalum dental implant. Among them, the top functional area is a dense structure; the middle functional area is a bionic bone trabecular porous structure; the bottom functional area is dense structure. The total length is 16mm, the diameter is 6mm, the length of the top functional area is 5mm, the length of the middle functional area is 7mm, and the length of the bottom functional area is 4mm. There are threads for mechanical fixation on the outside of the top functional area, with a depth of 1mm; the upper surface has an inner hexagonal groove for connecting the abutment, with a depth of 3mm and a diameter of 3mm. The central functional area is a bionic bone trabecular porous structure with an average pore diameter of 500 μm, an average wire diameter of 300 μm, a porosity of 70%, and a pore connectivity of 99%; the...

Embodiment 2

[0065] Use professional modeling software to design the structure of the three functional areas, and build a three-dimensional model of the trabecular bone porous tantalum dental implant. Among them, the top functional area is a dense structure; the middle functional area is a bionic bone trabecular porous structure; the bottom functional area is dense structure. Overall length 13mm, diameter 5mm, top length 4mm, middle length 5mm, bottom length 4mm. On the outer side of the top functional area, there are threads for mechanical fixation, with a depth of 0.8mm; on the upper surface, there are inner hexagonal grooves for connecting the abutment, with a depth of 2mm and a diameter of 3mm. The central functional area has a bionic bone trabecular porous structure, with an average pore size of 470 μm, an average wire diameter of 330 μm, a porosity of 75%, and a pore connectivity of 99%; the center of the porous structure has an internal reinforcing column with a diameter of 2.5 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com