Cutting and polishing integrated device for standard test block of stratified soft rock and use method

A standard test block, cutting and grinding technology, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problem that layered soft rock blocks are easy to be damaged, it is difficult to prepare standard test blocks, and the difficulty of fixing methods Large and other problems, to achieve good application prospects and practical value, easy to operate and maintain, to ensure the effect of surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

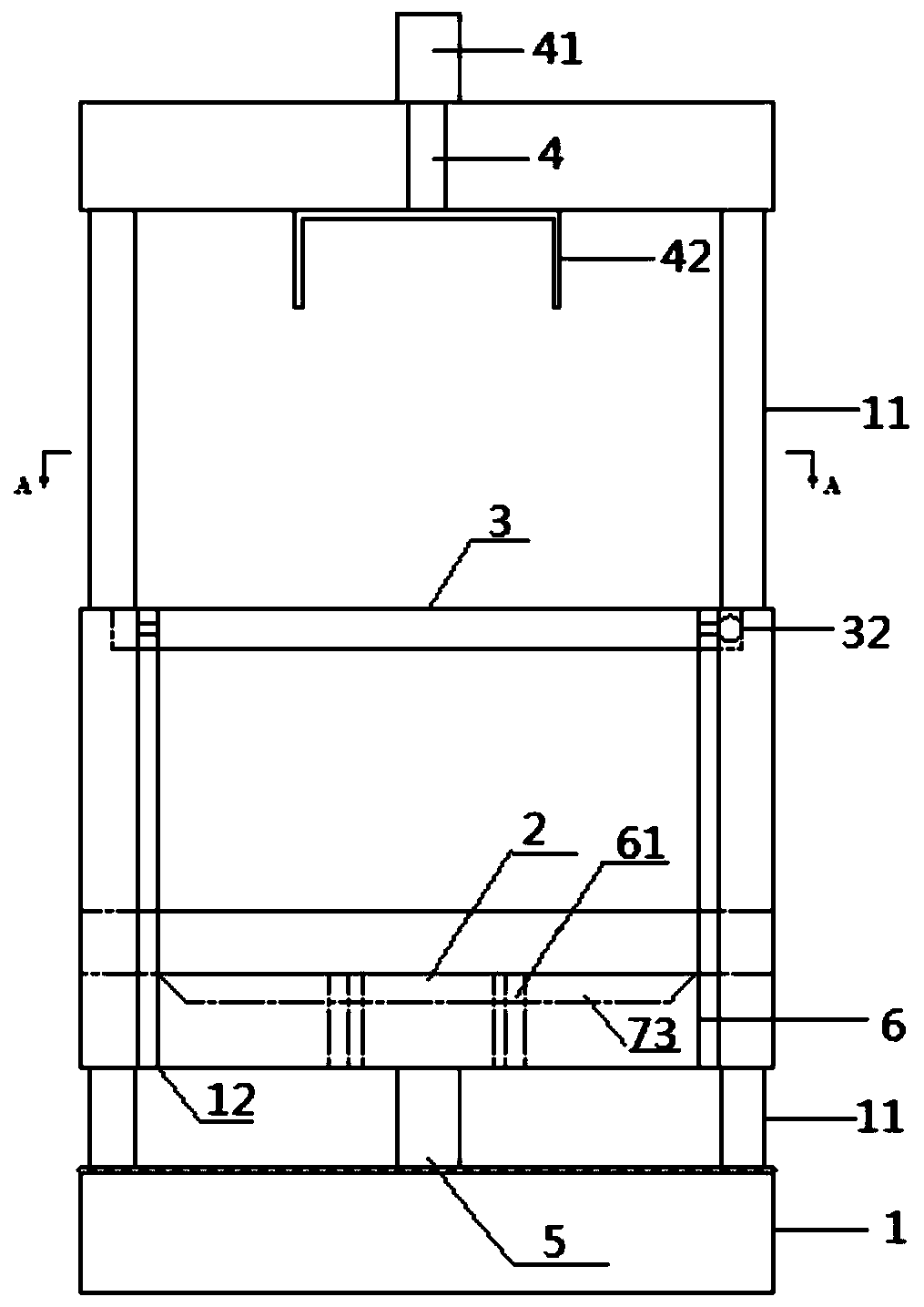

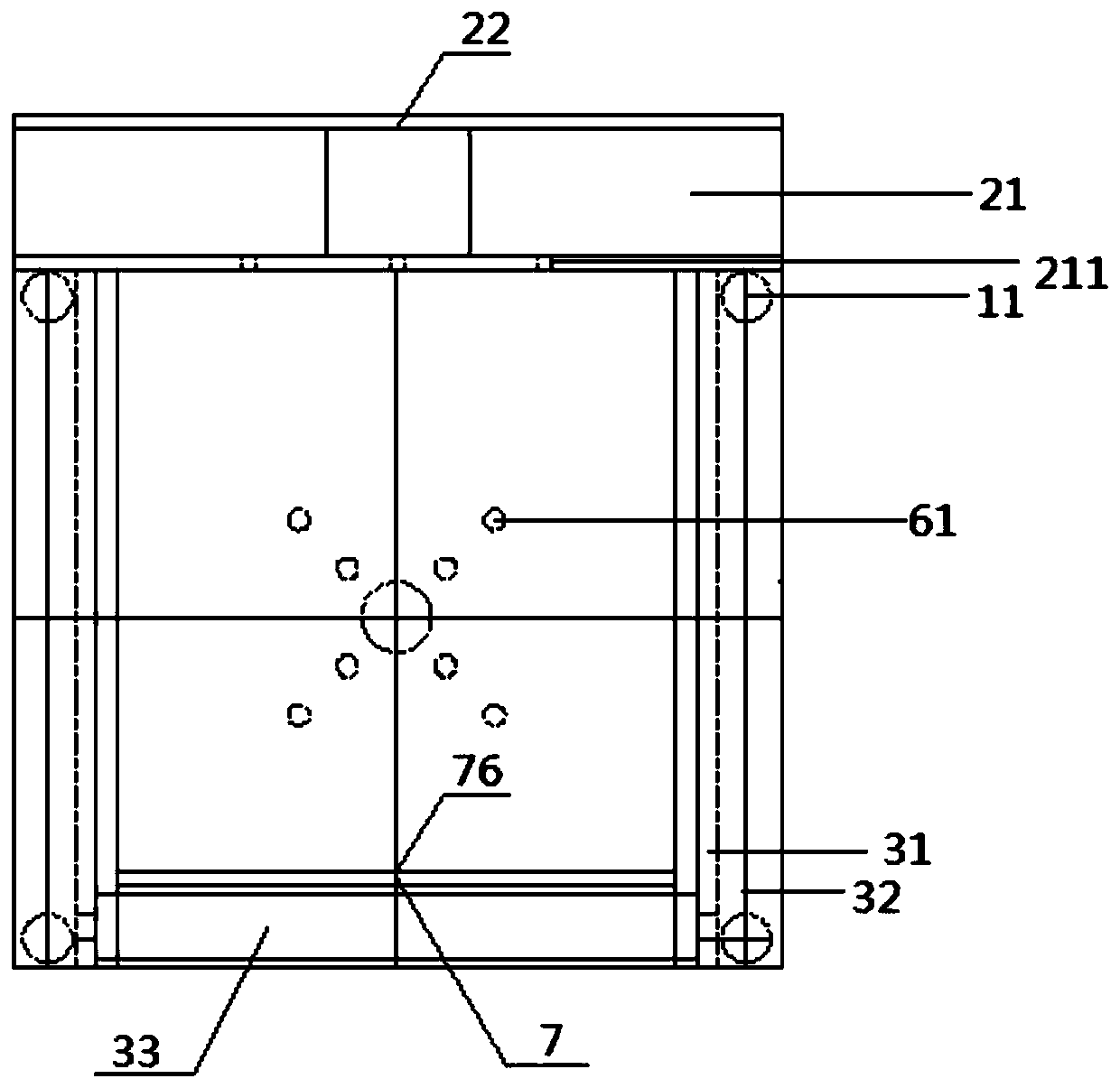

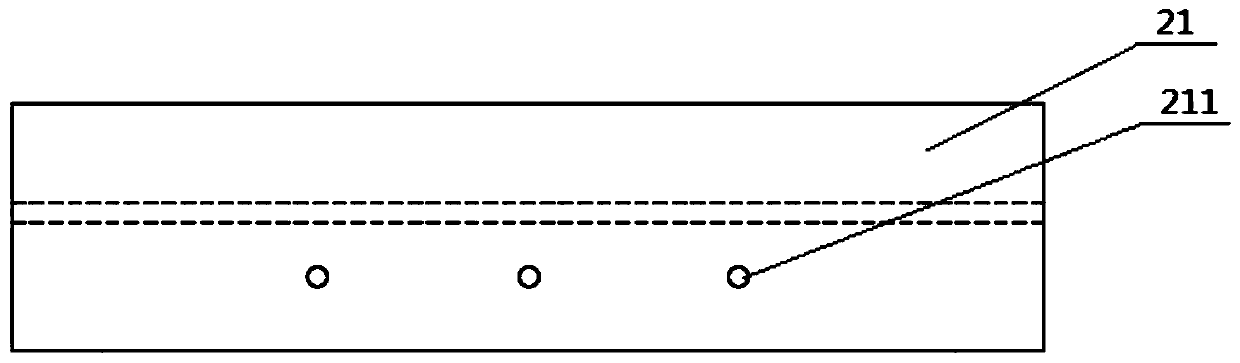

[0051] An exemplary embodiment of the present invention is basically as figure 1 and figure 2 As shown: this embodiment provides an integrated device for cutting and grinding standard test blocks of layered soft rock. The mobile cutting mechanism 2 and the horizontal grinding mechanism 3 on the first floor and the turntable mechanism 4 on the third floor; among them, support columns 11 are arranged and fixed around the base 1 on the first floor so that the device forms a frame structure, and the surrounding support columns 11 Extend upwards and pass through the second layer to the third layer in order to support the mobile cutting mechanism 2 and the horizontal grinding mechanism 3 on the second layer and the turntable mechanism 4 on the third layer; where the turntable mechanism 4 is supported on both sides The middle position of column 11.

[0052] An oil hydraulic device 5 is also installed on the base 1 as a lifting mechanism to support the mobile platform 6 located on ...

Embodiment 2

[0061] Embodiment 2 is basically the same as Embodiment 1, and the difference is that: as a preferred solution of the above-mentioned horizontal grinding mechanism 3, a second motor (not shown) is installed at the position where the driving slider is located, and the second motor is used to Drive the grinding tool 33 to rotate; In the present embodiment, the grinding tool 33 can be detachably connected with the output shaft of the second motor. structure, under the action of the second motor, the detachable grinding tool 33 rotates around its own circumferential direction; at the same time, the grinding tool 33 moves back and forth along the longitudinal guide rails 32 on the left and right sides under the action of the first motor of the drive assembly 31, so as to test the rock. The plane on the block is moved and polished to ensure the quality of the grinding.

[0062] on the other hand, figure 1 and figure 2 It shows a schematic diagram of an integrated device for cutti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com