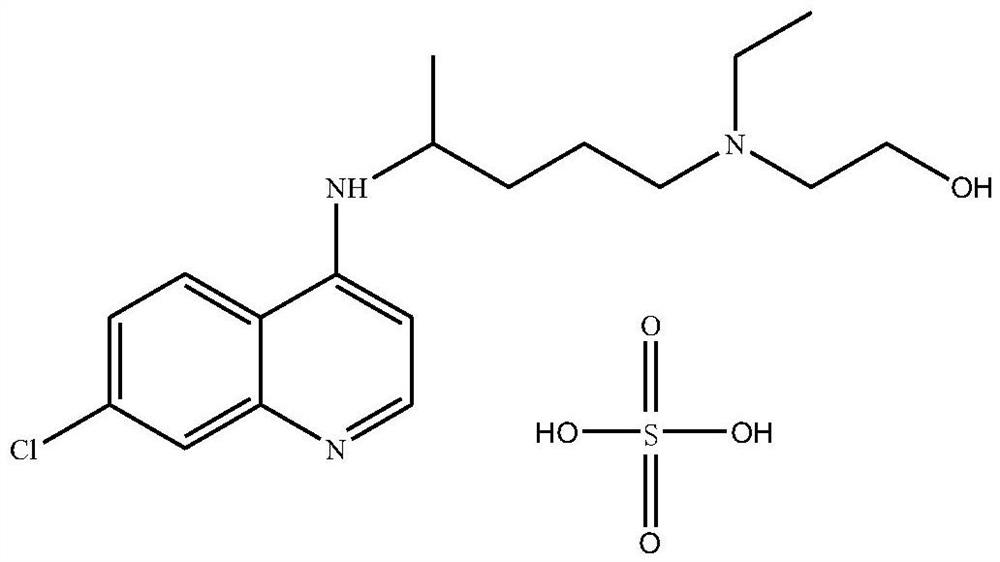

A method for continuous production of 5-(n-ethyl-n-2-hydroxyethylamine)-2-pentylamine

A technology of hydroxyethylamine and ethyl, which is applied in the field of continuous production of 5--2-pentylamine, can solve the problems of excessive waste discharge, cumbersome operation steps, serious environmental pollution, etc., and achieve improved economic benefits and simple reaction process High efficiency and low catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In some more specific embodiments, adopt co-precipitation method or deposition precipitation method to prepare and obtain described loaded nano-nickel-based catalyst; The preparation method of described loaded-type nano-nickel-based catalyst comprises:

[0033] Mix the mixed metal salt solution containing the main active component and the auxiliary agent, the lye with the metal salt solution of the carrier, the carrier oxide powder solution, and the carrier colloid particle solution at a pH of 9.5-10 A precipitation reaction occurs, followed by aging treatment at 30-100°C for 2-24h, then roasting at 400-800°C for 2-10h, and then reduction treatment at 400-750°C for 2-8h in a reducing atmosphere to obtain the supported Nano-nickel-based catalysts.

[0034] Further, the lye includes any one or a combination of two or more in sodium hydroxide solution, potassium hydroxide solution, sodium carbonate solution, potassium carbonate solution, and is not limited thereto.

[003...

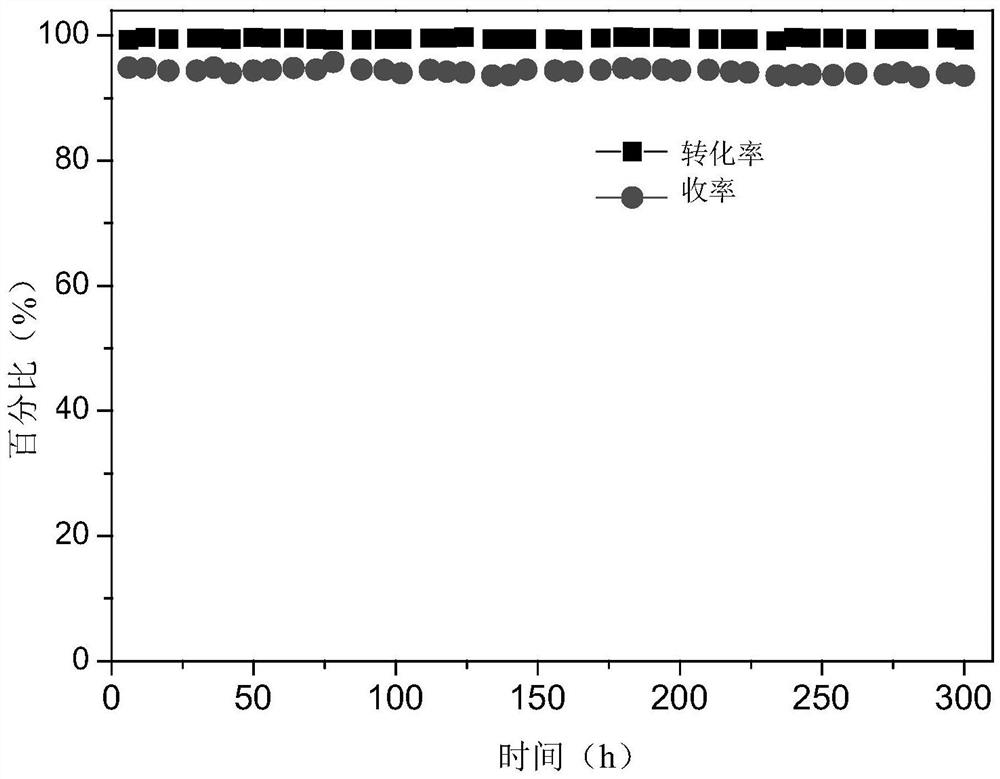

Embodiment 1

[0046] 66.88g Ni(NO 3 ) 2 ·6H 2 O, 2.17g Cu(NO 3 ) 2 ·3H 2 O, 117.0g Al(NO 3 ) 3 9H 2 O was added into 1100ml deionized water successively to prepare a 0.5mol / L metal salt solution A; 40g NaOH and 21.2g NaOH 2 CO 3 Add 200ml of deionized water to make a mixed alkaline solution B; add salt solution A and alkaline solution B dropwise to a 2000ml three-necked flask at the same time under rapid stirring, keep the pH of the precipitation process = 10±0.2, and raise the temperature to 80°C after the precipitation is completed After aging for 4 hours, filter after aging, and wash with deionized water until the filtrate is neutral. The filter cake was dried at 110°C for 12h and calcined at 400°C for 10h. Tablet sieve 20-40 mesh catalyst particles, fill 4g in a fixed-bed reactor, heat up to 550°C for 4 hours in a hydrogen atmosphere (flow rate 100mL / min) and reduce for 4 hours to obtain activated catalyst 1, the composition of the catalyst and the active metal Ni The grain s...

Embodiment 2

[0048] 60.45g NiSO 4 ·6H 2 O, 8.71g CoSO 4 ·7H 2 O, 95.97g Al 2 (SO 4 ) 3 18H 2 O is added to 810ml deionized water successively to prepare metal salt solution A of 0.5mol / L; the preparation of mixed alkali solution B and catalyst precipitation is the same as in Example 1; Wash with water until the filtrate is neutral. The filter cake was dried at 110°C for 12h and calcined at 500°C for 6h. Tablet sieve 20-40 mesh catalyst particles, fill 4g in a fixed bed reactor, heat up to 500°C and reduce for 6h in a hydrogen atmosphere (flow rate 100mL / min) to obtain activated catalyst 2, the composition of the catalyst and the active metal Ni The grain sizes are listed in Table 1. Weigh 5-(N-ethyl-N-2-hydroxyethylamine)-2-pentanone, ethanol, and 25% concentrated ammonia water in a mass ratio of 1:1:3 to prepare a reaction solution. At a reaction temperature of 120°C, H 2 Pressure 0.2MPa, H 2 The molar ratio to 5-(N-ethyl-N-2-hydroxyethylamine)-2-pentanone is 5:1 and the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com