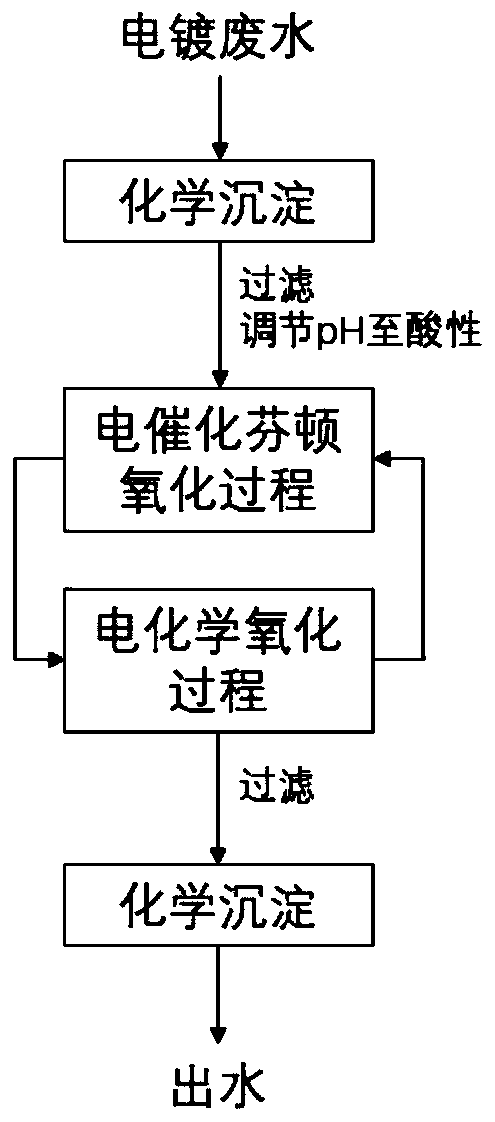

Double-oxidation device and method for advanced treatment of electroplating wastewater

A technology for electroplating wastewater and advanced treatment, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment and other directions, can solve the problem of low COD removal efficiency, avoid strong acid corrosion, efficient degradation, high electrocatalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Electro-Fenton / electrochemical double oxidation coupling process was used to treat galvanizing wastewater in an electroplating enterprise.

[0056] The influent COD of galvanized wastewater is 1444mg / L. Zinc ion concentration is 8.1g / L; chloride ion concentration is 46g / L, pH=2.

[0057] Step 1. The water sample is pretreated by the chemical precipitation method. will be 2.5m 3 The galvanizing wastewater is poured into the middle pool 4, the pH value is adjusted to 8.0-9.0 with caustic soda, and allowed to settle for 1 hour. After being filtered by the plate and frame filter press 5, the water sample is injected into the double oxidation reaction tank 3, and the pH is adjusted to 3.0-4.0.

[0058] Step 2, electrocatalytic Fenton oxidation process: the galvanized production wastewater circulates in the double oxidation reaction tank 3 and the electrochemical oxidation unit 2 (the power supply of the electrochemical oxidation unit 2 is not turned on during the electroc...

Embodiment 2

[0079] The electro-Fenton / electrochemical double oxidation coupling process was used to treat the chromium plating production wastewater of an electroplating enterprise.

[0080] Influent COD of wastewater from chrome plating production is 2127mg / L. Chromium ion concentration is 7.7g / L; chloride ion concentration is 37g / L, pH=1.5.

[0081] Step 1. The water sample is pretreated by a redox method. will be 2.5m 3 The chrome-plating waste water is poured into the middle pool 4, and the water sample is yellow at this time, and sodium sulfite is added in the middle pool 4 until the water sample turns dark green and stops adding. Due to Cr in chrome plating wastewater 6+ It has strong oxidizing properties, which will greatly interfere with the electrocatalytic Fenton oxidation reaction, and will also corrode the tubular membrane electrode of the electrochemical oxidation unit 2, so it is necessary to remove the Cr 6+ reduced to Cr 3+ .

[0082] Step 2, using the chemical preci...

Embodiment 3

[0095] The electro-Fenton / electrochemical double oxidation coupling process was used to treat the tin-plating wastewater of an electroplating enterprise.

[0096] Influent COD of tinning production wastewater = 1643mg / L. The tin ion concentration is 9.6g / L; the chloride ion concentration is 39g / L, pH=1.7.

[0097] Step 1. The water sample is pretreated by the chemical precipitation method. will be 2.5m 3 The tin-plating waste water is poured into the intermediate pool 4, and the pH value is adjusted to 8.0-9.0 with caustic soda, and left to settle for 1 hour. After being filtered by the plate and frame filter press 5, the water sample is injected into the double oxidation reaction tank 3, and the pH is adjusted to 3.0-4.0.

[0098] Step 2, electrocatalytic Fenton oxidation process: the tin-plating production wastewater circulates in the double oxidation reaction tank 3 and the electrochemical oxidation unit 2 (the power supply of the electrochemical oxidation unit 2 is not tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com