Efficient slump retaining agent and preparation method thereof

A slump-retaining agent and high-efficiency technology, applied in the field of building materials, can solve the problems of high mud content and stone powder content in sand and gravel, slow down the construction progress, and greatly fluctuate in cement quality, and achieve the goal of improving workability and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

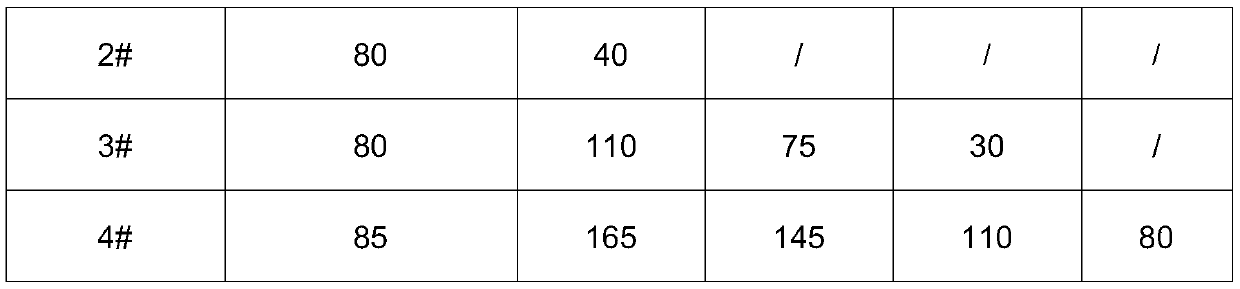

Image

Examples

Embodiment 1

[0033] Take 200g of hydroxybutyl vinyl polyglycol ether and 196g of water, put them in a three-necked flask, and stir mechanically at 40°C until the hydroxybutyl vinyl polyglycol ether is completely dissolved; add 1g of hydrogen peroxide, continue Stir for 5 minutes; stir 0.45g of sodium vitamin C, 1g of mercaptoethanol, and 38g of water in a beaker and start to drop them into a three-neck flask at a rate of 0.2g / min; after 10 minutes, add 7.6g of acrylic acid, 24.5g of hydroxyethyl Ester and 4g monomer diacrylamide dimethyl propane sulfonic acid were stirred evenly in a beaker and then added dropwise into a three-necked flask at a rate of 0.49g / min; after 3h, the dropwise addition was completed, and then the temperature was continued for 0.5h. After the reaction is finished, the material is discharged to obtain the product.

Embodiment 2

[0035] Mix 190g of prenyl polyethylene glycol ether and 203g of water under mechanical stirring at 45°C until completely dissolved; add 1g of hydrogen peroxide and continue stirring for 5 minutes; mix 0.5g of sodium vitamin C, 0.9g of mercaptoethanol, and 43g of water Stir evenly in the beaker and start to drop into the three-necked flask at a rate of 0.22g / min; 1. Stir 7g of acrylamide in the beaker and add it dropwise into the three-necked flask at a rate of 0.53g / min; after 3.5h, the dropwise addition is completed, and then continue to keep warm for 1h. After the reaction is finished, the material is discharged to obtain the product.

Embodiment 3

[0037] Mix 210g of hydroxybutyl vinyl polyethylene glycol ether and 195g of water under mechanical stirring at 50°C until completely dissolved; add 1g of ferrous sulfate and continue stirring for 10min; mix 0.56g of sodium vitamin C, 0.86g of mercaptoethanol, and After the water was stirred evenly in the beaker, it began to be added dropwise into the three-necked flask at a rate of 0.23g / min; Acrylamide dimethyl propane sulfonic acid was stirred evenly in the beaker and then added dropwise into the three-necked flask at a rate of 0.56g / min; the dropwise addition was completed in 3.5h, and then continued to keep warm for 1h. After the reaction is finished, the material is discharged to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com